Cattle feed transfer trolley

A transfer vehicle and cattle feed technology, which is applied to trolleys, motor vehicles, multi-axis trolleys, etc., can solve the problems of easy lumping and cumbersome work, and achieve the effects of improving efficiency, saving labor, and increasing the dumping angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

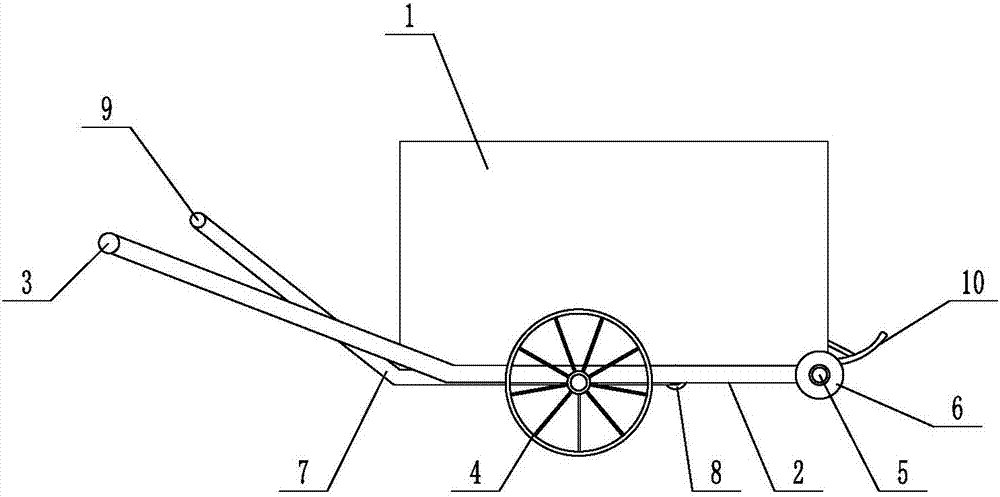

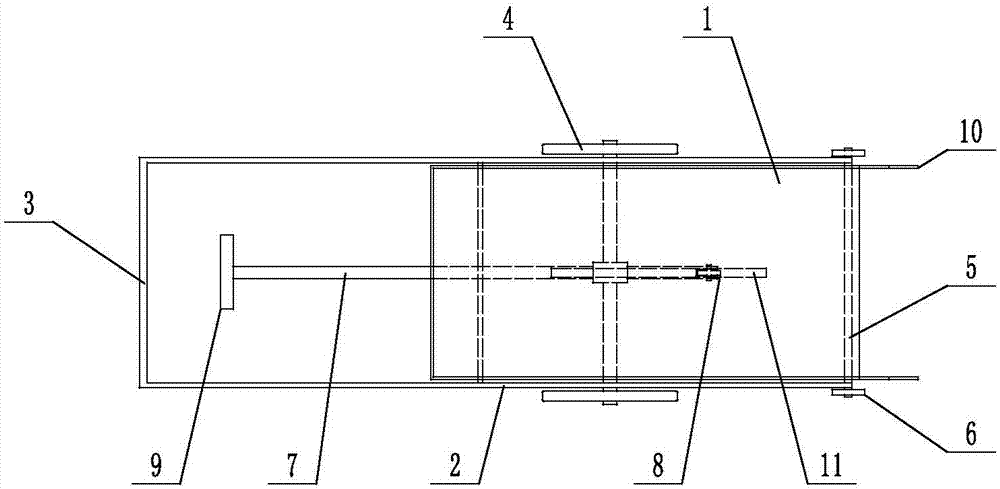

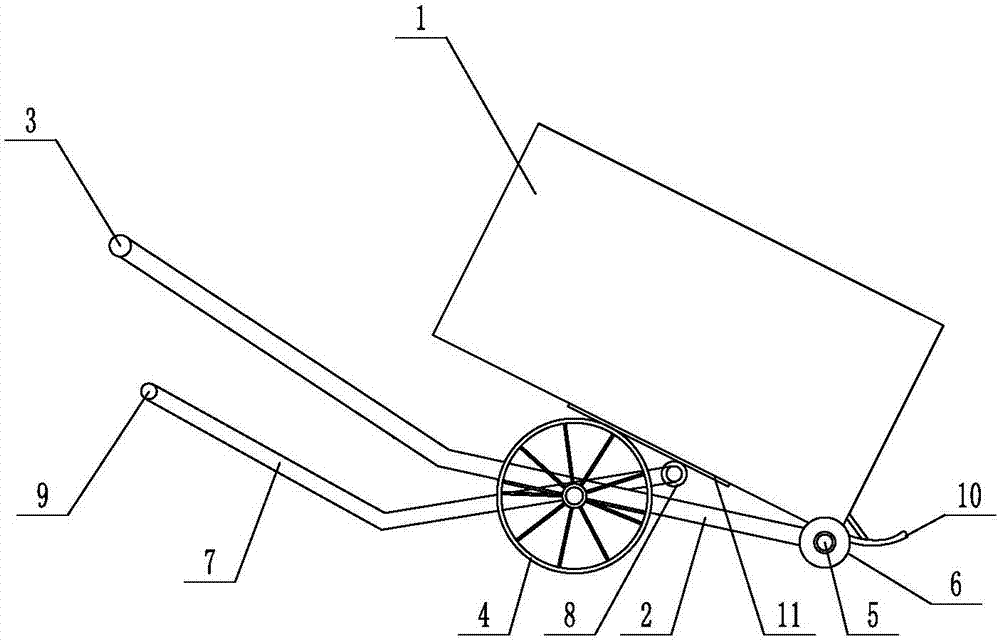

[0016] Such as Figure 1-3 As shown, the present invention comprises material box 1, vehicle frame 2, the handle 3 that is located at the left end of vehicle frame 2, the wheel 4 that is connected in the middle of vehicle frame 2 by bearing, and the right end of described material box 1 is connected with vehicle frame 2 by rotating shaft 5. The right end is connected, and the two ends of this rotating shaft 5 are connected with auxiliary wheel 6 by bearing.

[0017] The lower end of the vehicle frame 2 is connected with a crowbar 7 through a bearing, and the right end of the crowbar 7 is connected with a pry wheel 8 through a bearing, and the right end extends to the left end of the discharge box 1, and the left end of the crowbar 7 is provided with a horizontal pressing pole 9.

[0018] Both sides of the right end of the material box 1 are fixedly connected with limit rods 10 .

[0019] The lower end of the material box 1 is provided with a reinforcing plate 11 matched with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com