Cleaning device used for hollow glass production

A cleaning device and glass technology, which is applied in the directions of cleaning methods using liquids, transportation and packaging, cleaning of flexible items, etc. The overall structure is compact and reasonable, the installation is convenient, and the structure design is reasonable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

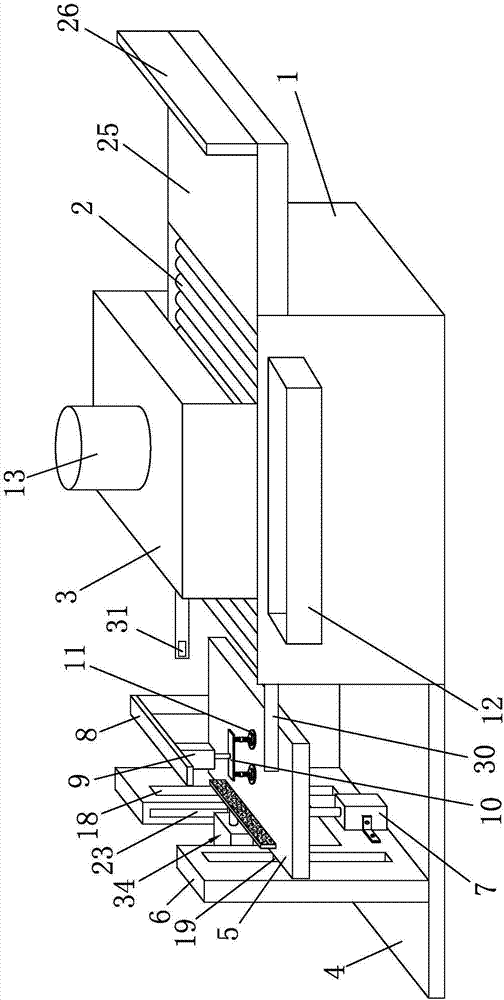

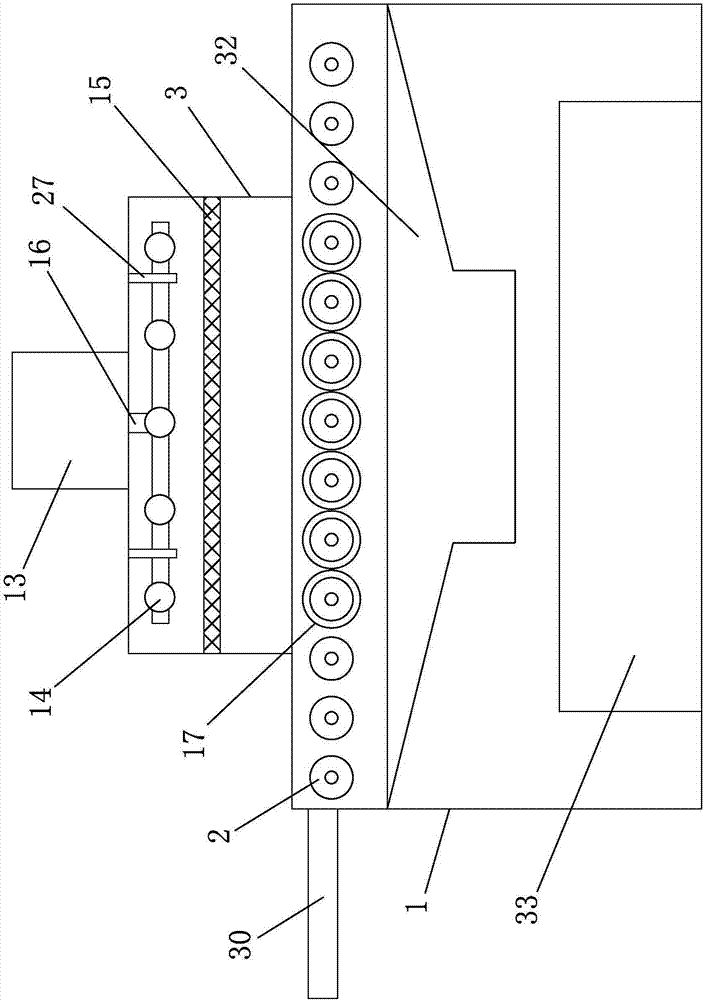

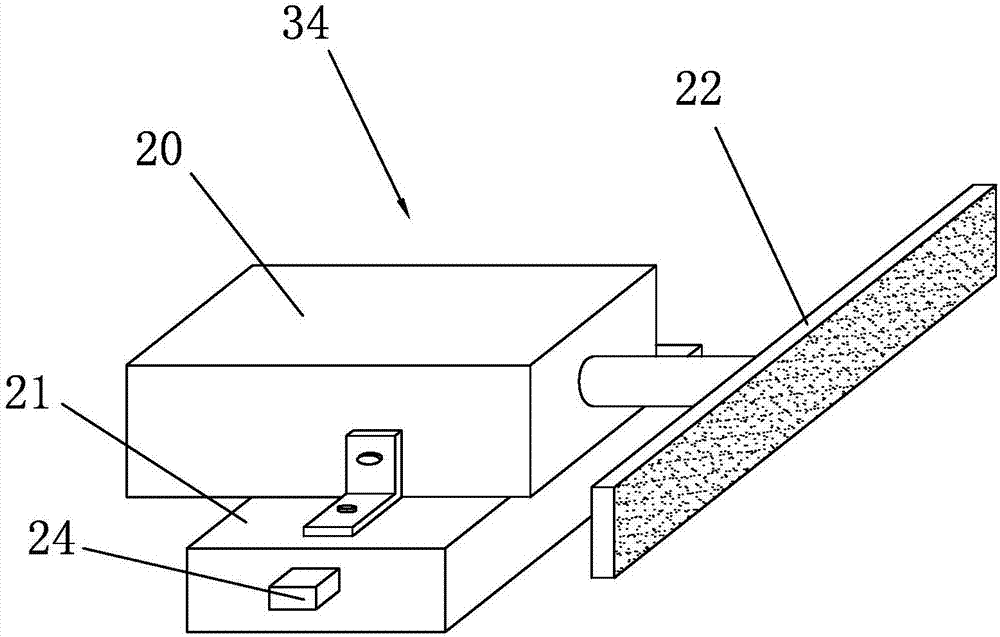

[0025] like Figure 1 to Figure 4 As shown, it is a cleaning device for the production of insulating glass according to the present invention, which includes a feeding assembly, a cleaning platform 1, a conveying roller 2 and a cleaning chamber 3. The feeding assembly is fixedly connected to the left end surface of the cleaning platform 1 through a mounting plate 4, and the feeding The assembly includes a lifting device, a pushing device 34 and a limiting device. The lifting device includes a lifting plate 5, a sliding plate 6 and a lifting cylinder 7. The sliding plate 6 is in a "concave" shape, and a limiting chute is arranged on the inner wall of the sliding plate 6. 23. The moving plate 21 is embedded in the limit chute 23 through the embedding block 24, and moves up and down along the limit chute 23. The design of the shape of the sliding plate 6 can facilitate the fixing and installation of the pushing device 34 and the lifting device. The structure The design is more re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com