Rapid flour kneading machine

A fast, flour-based technology, applied in dough mixers, structural parts of mixing/kneading machines, dough fermenters, etc., can solve the problems of insufficient dough elasticity, affecting food taste, and inability to ferment dough, etc., to achieve multiple kneading angles, Guarantee the controllability of fermentation, ensure the quality and freshness of fermentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

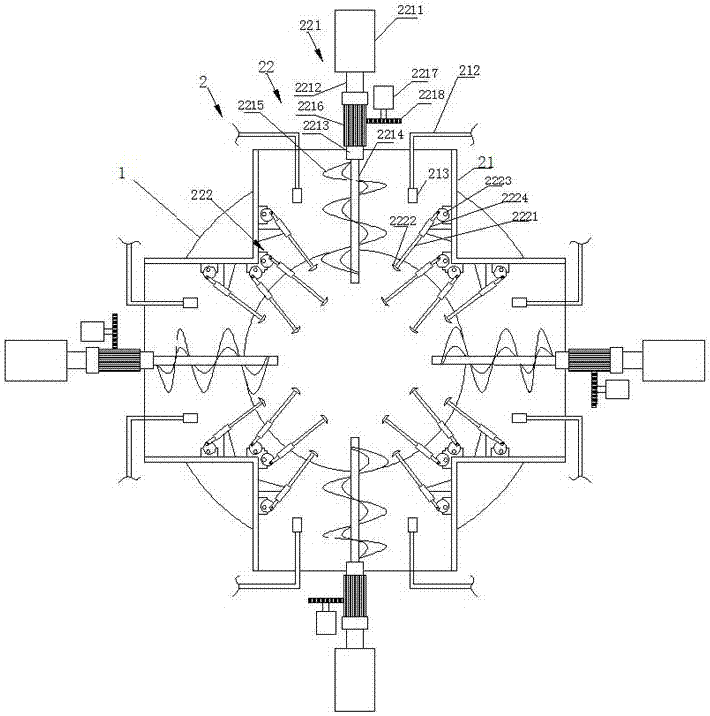

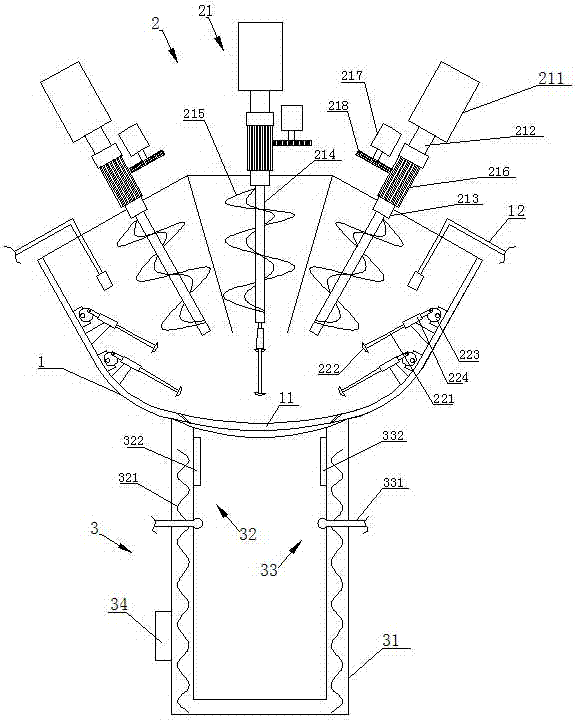

[0022] like Figures 1 to 3 As shown, a fast flour kneading machine includes a basin body 1 and a plurality of kneading noodle devices 2 arranged obliquely on the basin body 1; In the body 21 and extending to the dough mixing device 22 in the basin body 1; the telescopic water inlet pipe 212 facing the basin body 1 is arranged in the cylinder body 21; the end of the telescopic water inlet pipe 212 is a cylindrical self-rotating nozzle 213; The kneading device 22 includes a stirring device 221 that can be raised and lowered along the cylinder body 21 and extends into the basin body 1, and a beating device 222 evenly distributed on the inner periphery of the cylinder body 21; 1 inside the striker 2221; the end of the striker 2221 towards the basin body 1 is provided with a hemispherical hammer 2222, and the other end is hinged on the outer per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com