Loudspeaker voice diaphragm and making method thereof

A speaker and sound film technology, applied in the field of speaker sound film and its production, can solve the problems of increasing the degree of distortion of the speaker, shifting the sticking position, affecting the quality of the speaker, etc., to increase the degree of distortion, improve the quality, and avoid the degree of distortion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

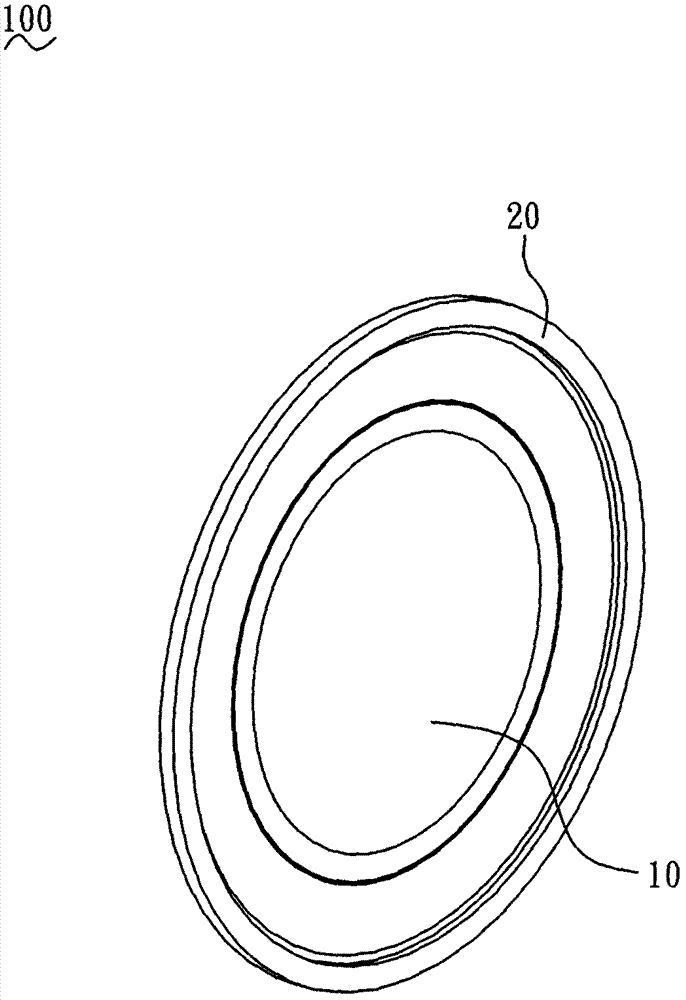

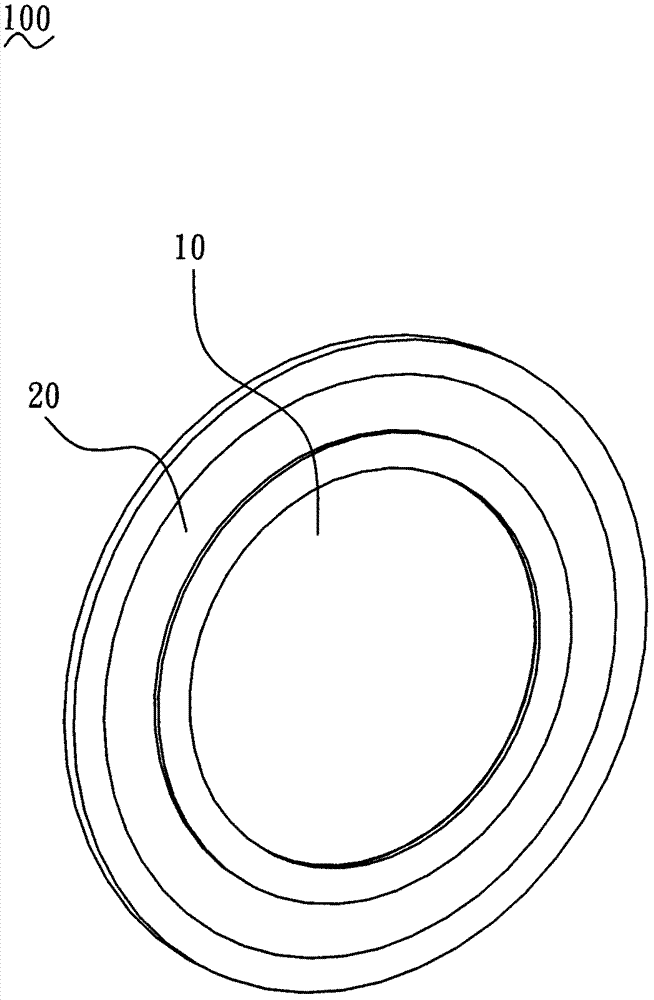

[0020] see figure 1 with figure 2 , a speaker sound film 100 is installed on a speaker (not shown in the figure), and includes a diaphragm 10 and an overhang portion 20 .

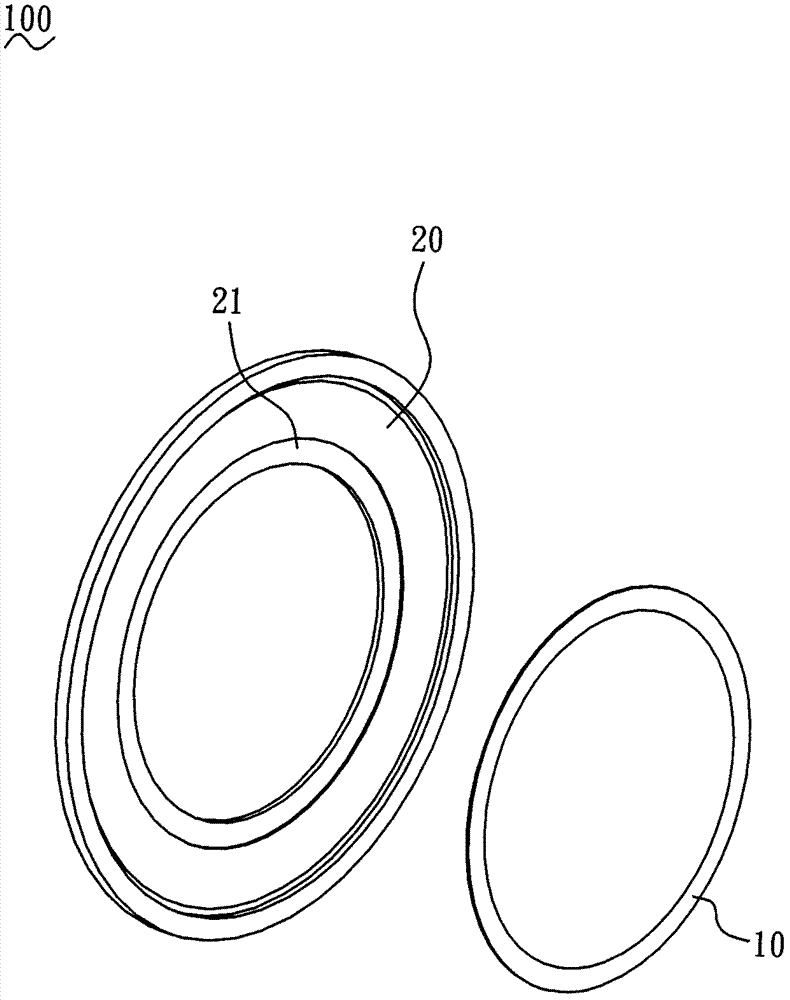

[0021] see image 3 , the diaphragm 10 is circular, made of acrylonitrile-butadiene-styrene copolymer (Acrylonitrile Butadiene Styrene, ABS) plastic, and a layer of nanometer material is electroplated on the surface.

[0022] The hanging edge portion 20 is in the shape of a ring, and is in-moulded on the outer periphery of the diaphragm 10 by room temperature vulcanized silicone rubber (RTV), and a circle is formed on the inner edge of the outer surface of the hanging edge portion 20. An annular mounting groove 21. The outer periphery of the diaphragm 10 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com