L type braided belt processing method

A processing method and braiding technology, which is applied in the direction of the tools that the ribbon passes through, textiles and papermaking, fabric surface trimming, etc., can solve the problems of easy reset, large included angle, and inability to complete the shaping of the braided tape, so as to achieve difficult reset, The effect of structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0019] A method for processing an L-shaped braided belt, the steps are as follows:

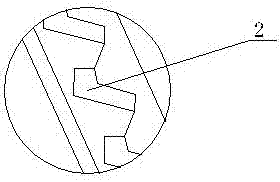

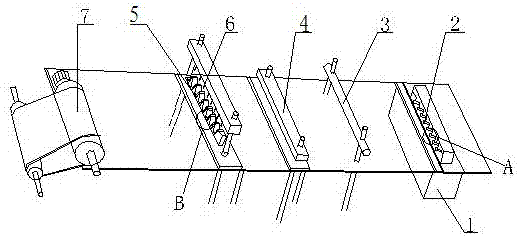

[0020] S1: The heating box 1 heats the first L-shaped perforation 2 of the mold mounting plate to 400 degrees, and inserts the braid into the heated first L-shaped perforation 2 to complete the preliminary shaping of the braid;

[0021] S2: The braid enters above the ejector rod 3 and penetrates into the pressing unit 4. After the pressing unit 4 presses and fixes the braid, the ejector rod 3 lifts up to straighten the braid to complete the straightening step of the braid;

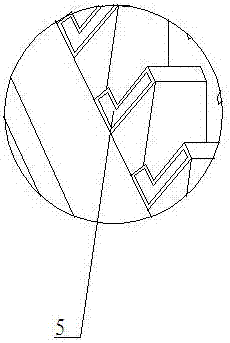

[0022] S3: The braiding tape continues to enter the second L-shaped perforation 5, and the top of the second L-shaped perforation 5 has a heated drilling needle 6, and the drilling needle 6 is continuously inserted up and down to complete the braiding tape perforation process;

[0023] S4: The perf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com