Sizing agent discharging device

A feeder and slurry technology, which is applied in the field of slurry filling devices, can solve problems such as difficulty in grasping, waste, and test errors, and achieve the effect of preventing insufficient addition amount and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

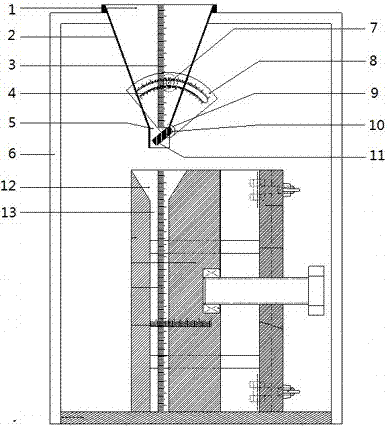

[0015] A slurry feeder, such as Figure 1-2 As shown, it includes a barrel 2 with a feed port 1 and a discharge port 5, a gate 11 for adjusting the opening of the discharge port 5, a gate shaft 10, a shaft sleeve 9, a turntable 8, and a turntable tightening screw 7 And the bracket 6, the barrel 2 is an inverted truncated cone structure, the discharge port 5 of the barrel 2 is a rectangular structure extending in the front and rear directions, and the length of the discharge port 5 matches the length of the simulated crack 13. The gate 11 is located at the discharge port 5 and is arranged on the barrel 2 through the pitch and rotation of the gate shaft 10. Specifically, the shaft sleeve 9 is arranged on the front and rear outer walls of the discharge port 5, and the gate shaft 10 is rotatably inserted in In the corresponding shaft sleeve 9, the turntable 8 is fixedly arranged with the gate 11 through the gate shaft 10, the turntable 8 has an arc-shaped slot, and at least one sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com