Self-restoring ductility steel support adopting shape memory alloys (SMA)

A steel support, self-reset technology, applied in building types, buildings, building components, etc., can solve the problems of insufficient axial deformation capacity of self-reset steel supports, large additional stress on peripheral components, and large amount of SMA wire, and achieves a wide range of projects. Application prospect, convenient construction, good anti-fatigue performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

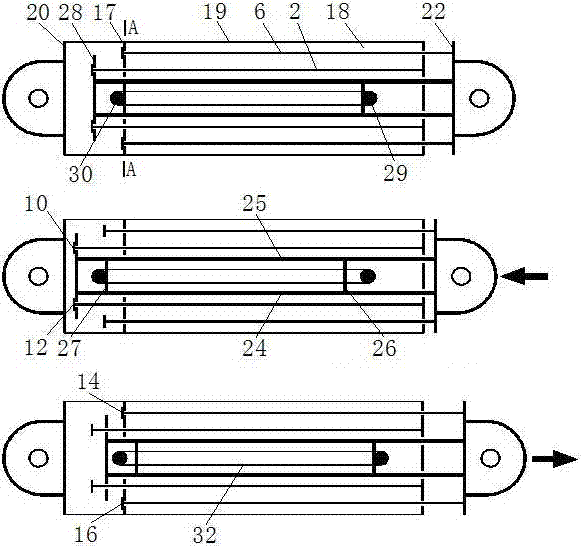

[0025] Such as Figure 1 to Figure 3 As shown, an SMA self-resetting ductile steel support includes a first energy-dissipating steel plate group, a second energy-dissipating steel plate group and a reset element group, wherein:

[0026] The upper part of the first energy-dissipating steel plate group is affixed to the first upper end plate 18, and the lower part of the first energy-dissipating steel plate group passes through an inner end plate 17 and an inner support end plate 28 in sequence, and passes through the first end anchor The tool is anchored on the lower surface of the inner support end plate 28;

[0027] The upper part of the second energy-dissipating steel plate group is fixed on the second upper end plate 22, and the lower part of the second energy-dissipating steel plate group passes through the inner end plate 17 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com