Waste plastic bottle cap and body label removing aftertreatment system

A technology for waste plastics and bottle caps, used in plastic recycling, granular material drying, mechanical material recycling, etc., can solve the problems of incomplete drying of plastic granules, time-consuming and laborious, poor efficiency, etc., and achieve easy drying of materials and complete drying. Moisture, easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

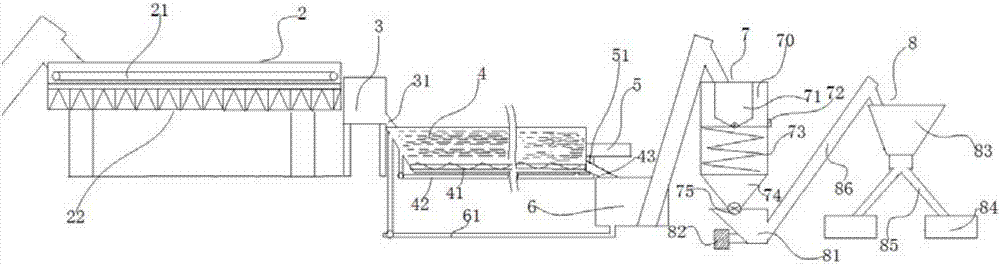

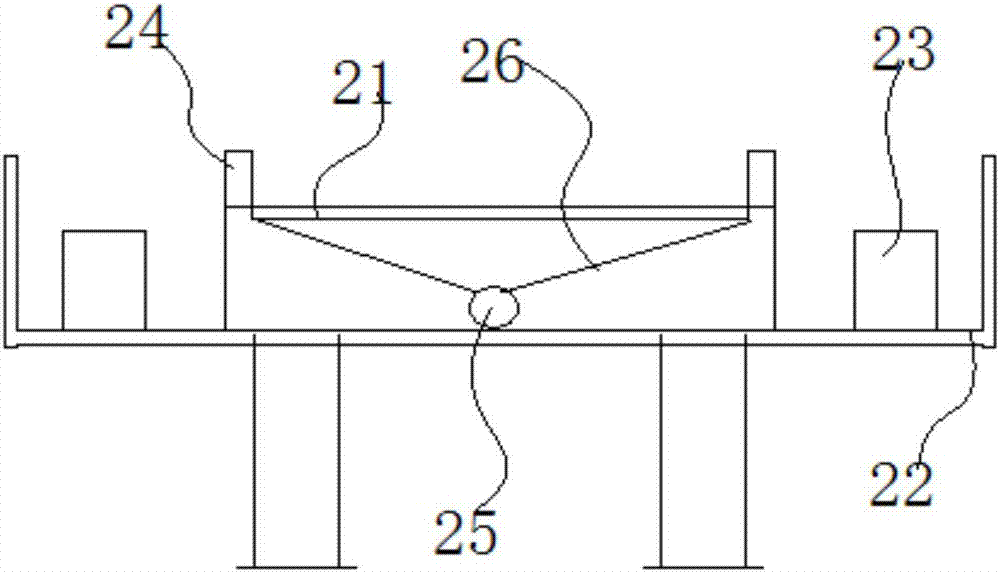

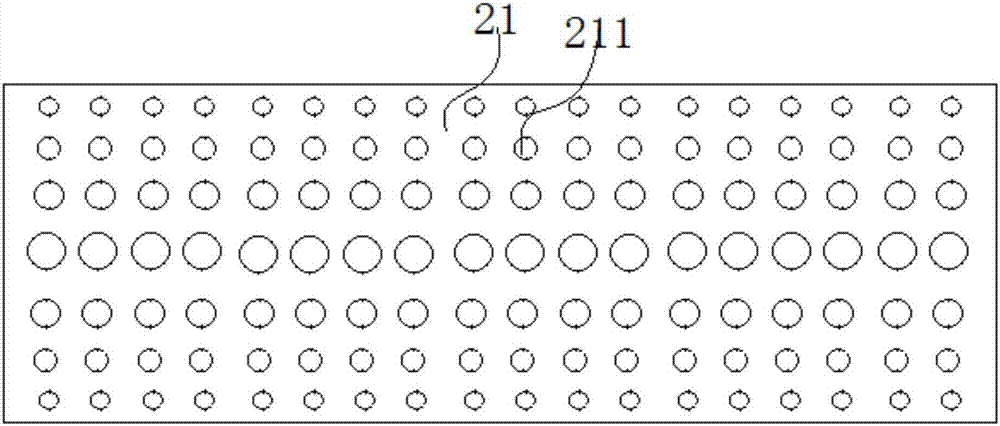

[0041] The post-processing system of the waste plastic bottle cap bottle of the present embodiment demarking, such as figure 1 As shown, it includes the first feeding auger, the selection platform 2, the crusher 3, the separation tank 4, the plastic collection box 6, the second feeding auger, the dehydration device 7 and the packaging mechanism 8 arranged in sequence according to the process. The blanking opening at the upper end of a feeding auger is facing the beginning of the selection platform 2, and the tail end of the selection platform 2 is fed into the crusher 3; The platform 22; the crusher 3 communicates with the beginning of the separation tank 4 through the discharge port 31; the end of the separation tank 4 communicates with the plastic pellet collection box 6 through the plastic pellet discharge port 43; the separation tank 4 is filled with Separation liquid; the plastic particle collection box 6 communicates with the dehydration device 7 through the second feedi...

Embodiment 2

[0044] The basic structure of the waste plastic bottle cap bottle removal post-processing system of this embodiment is the same as that of Embodiment 1, the difference and improvement are: the dehydration device 7 is a hot air channel, and there is a horizontal auger in the channel, and the temperature of the hot air is 60-80 °C ;

[0045] The production process of the waste plastic bottle cap bottle delabeling post-processing system of the present embodiment, the steps are:

[0046] A. Loading selection: The waste plastic bottle body separated from the bottle and the label is lifted to the top of the selection platform through the first feeding auger, and dropped to the surface of the horizontal conveyor belt 21 through the discharge port, and the operator walks on the platform. On 22, the waste plastic bottle body with residual label on the horizontal conveyer belt 21 is selected;

[0047] B. Crushing: Transfer the selected waste plastic bottle body to the crusher 3 for cru...

Embodiment 3

[0053] The post-processing system for waste plastic bottle caps and bottles in this embodiment has the same basic structure as that in Embodiment 1. The difference and improvement is that a defective product collection box 23 is placed on the walking platform 22 to facilitate the collection of bottles with residual labels. After the defective product is recovered, it is returned to the furnace for processing; Figure 5 As shown, the end of the separation tank 4 has an overflow port 44, and the overflow port 44 is connected to the bottle cap collection box 5; because the composition of the bottle cap is LD-PE, its density is less than water, so it floats on the water surface and passes through the overflow port. The port 44 overflows it into the bottle cap collection box 5 and carries out subsequent dehydration treatment after being collected; the dehydration device 7 includes a discharge switch 75 at the discharge port at the bottom of the oven 70 and the oven 70; the packaging...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com