Tooling for quick disassembly of shaft sleeve workpieces

A shaft sleeve and workpiece technology, which is applied in the field of tooling for quickly disassembling shaft sleeve workpieces, can solve problems such as slow efficiency, shaft sleeve knocking damage, time-consuming and laborious, etc., to reduce labor intensity, low cost, and improve disassembly efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

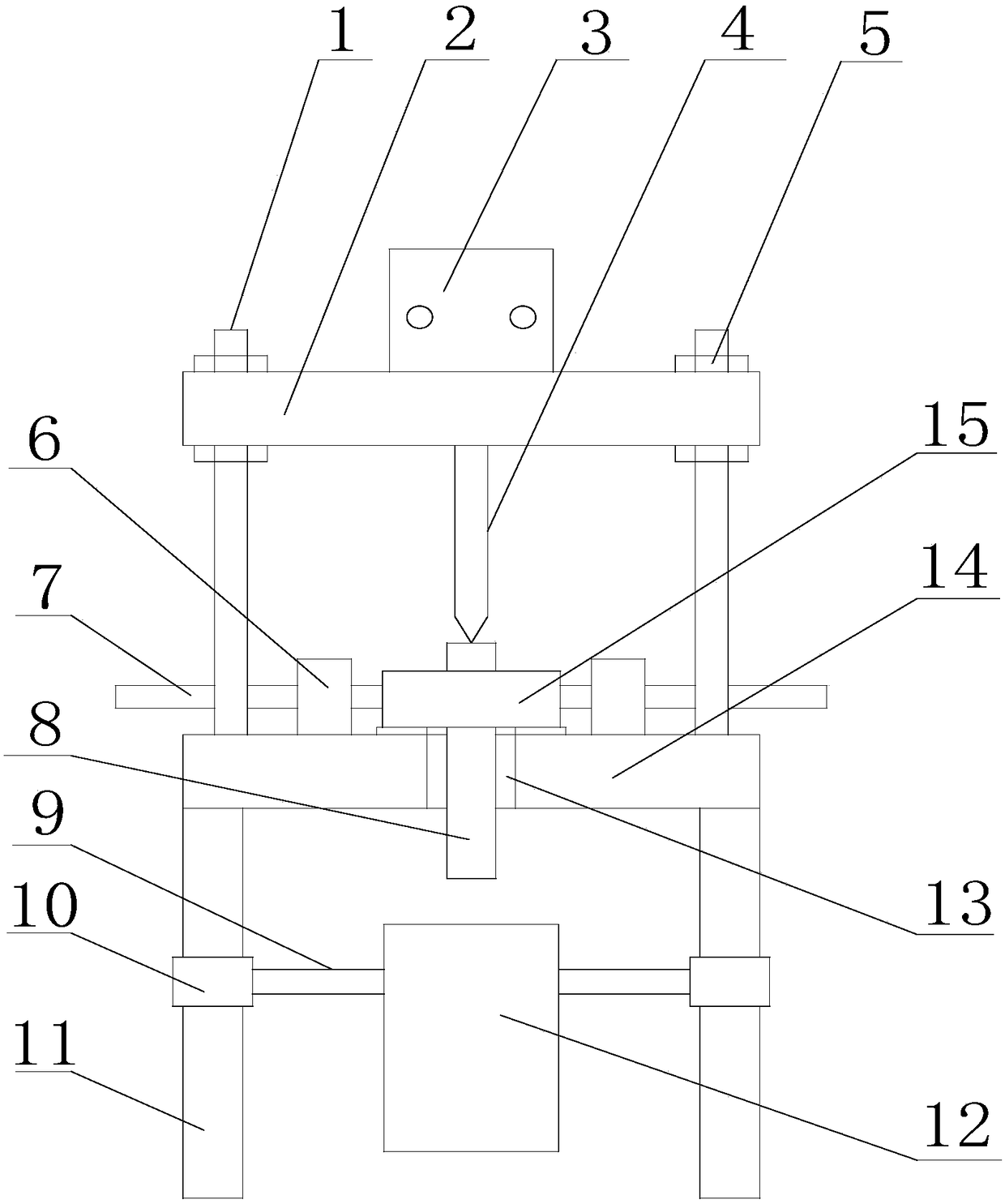

[0024] Such as figure 1 , figure 2 As shown, the tooling of the present invention for quickly disassembling the sleeve workpiece includes a rectangular operating table 14 and support feet 11 arranged at the four corners of the bottom of the operating table 14. The top of the operating table 14 is provided with a through hole 17 through which The hole 17 is located at the central position of the console 14, and the through hole 17 connects the top and the bottom of the console 14. The top of the console 14 is also provided with two bumps 6, and the two bumps 6 are respectively located on the axis of the through hole 17. On both sides, the side walls of the two projections 6 are provided with movable rods 7, and the movable rods 7 are threaded through the projections 6. When the movable rods 7 are rotated, the movable rods 7 can move horizontally on the projections 6 Move, to realize the clamping of the shaft sleeve 15, the side wall of the operating table 14 is also provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com