Processing Technology of Band Saw Base

A processing technology and technology of band sawing machine, which is applied in the field of processing technology of band sawing machine base, can solve problems such as poor firmness of band sawing machine, poor welding sealing performance of band sawing window, poor welding sealing performance, etc., and achieve detection Simple and convenient, increase the sealing performance, reduce the effect of mechanical deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0038] A processing technology for a base of a band sawing machine, comprising the following steps:

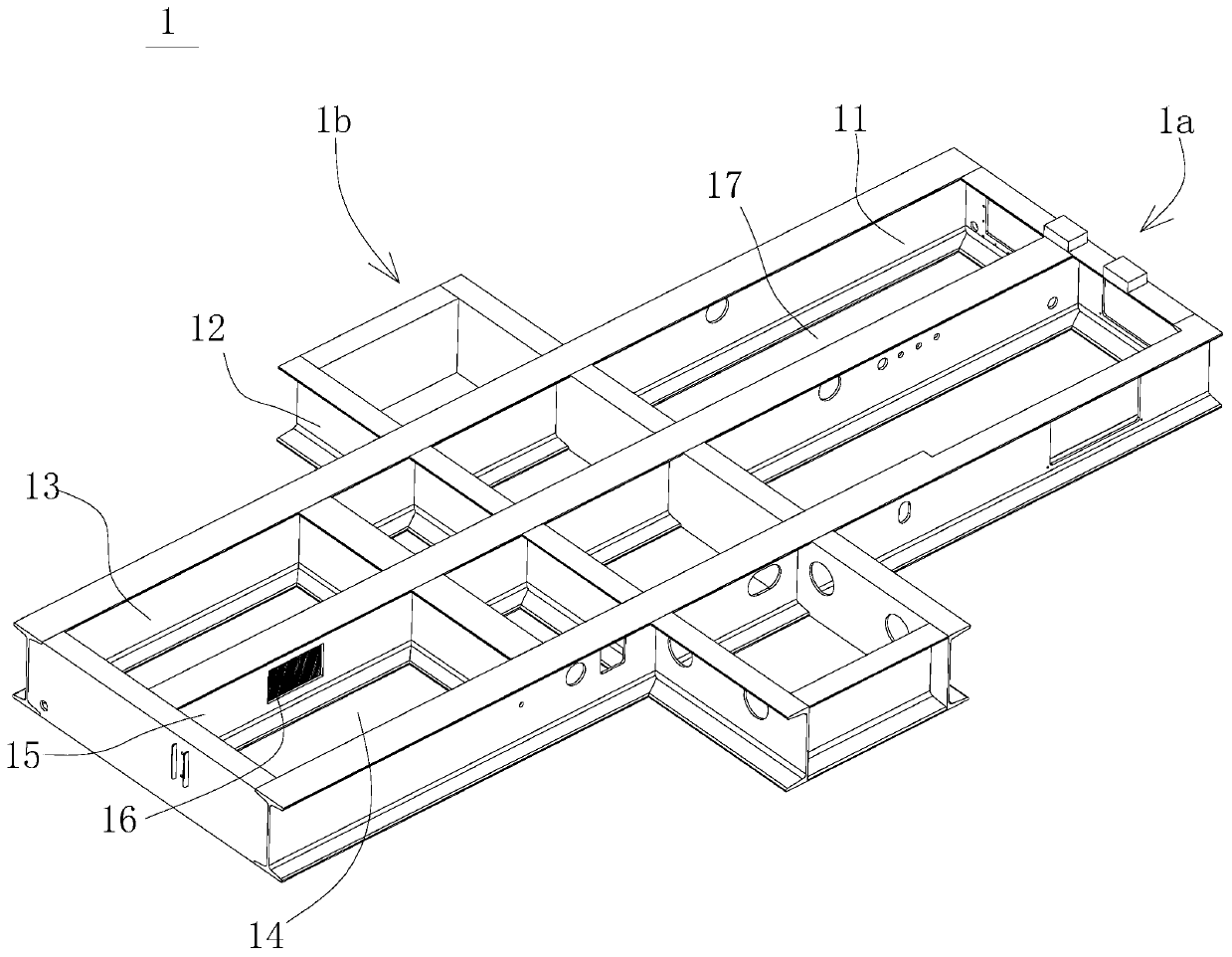

[0039] Refer to attached figure 1 , step a: welding three horizontal I-beams 11 and two vertical I-beams 12 to form a cross-shaped bottom frame 1 formed by interlacing the transverse section 1a and the longitudinal section 1b, and forming on the side of the transverse section 1a The two water tanks are the water storage tank 13 and the water outlet tank 14 which are adjacent to each other and communicate with each other. The water storage tank 13 and the water outlet tank 14 are separated by a partition 15, and a port is provided on the partition 15, and a filter screen is arranged on the port 16. The other side forms an oil tank 17.

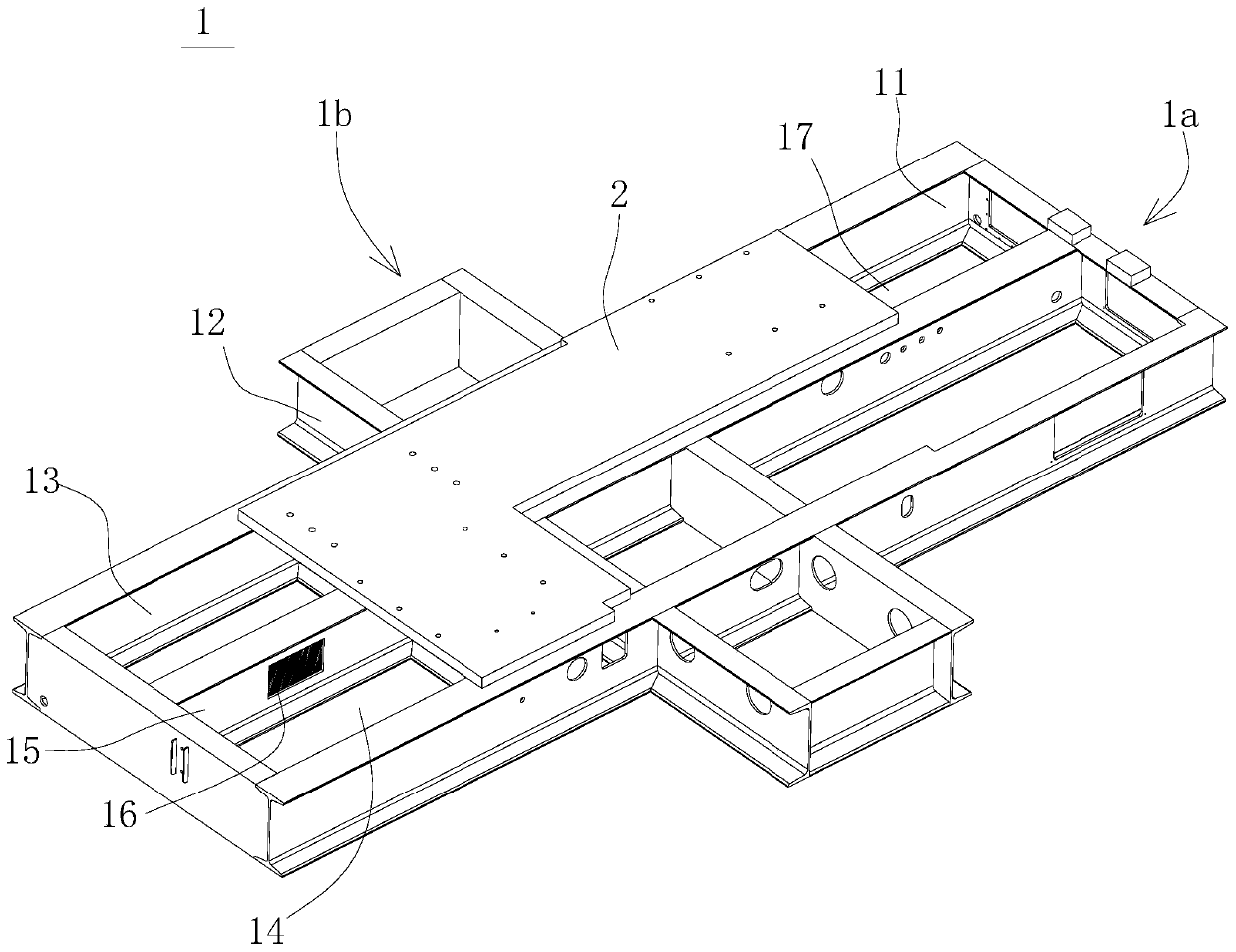

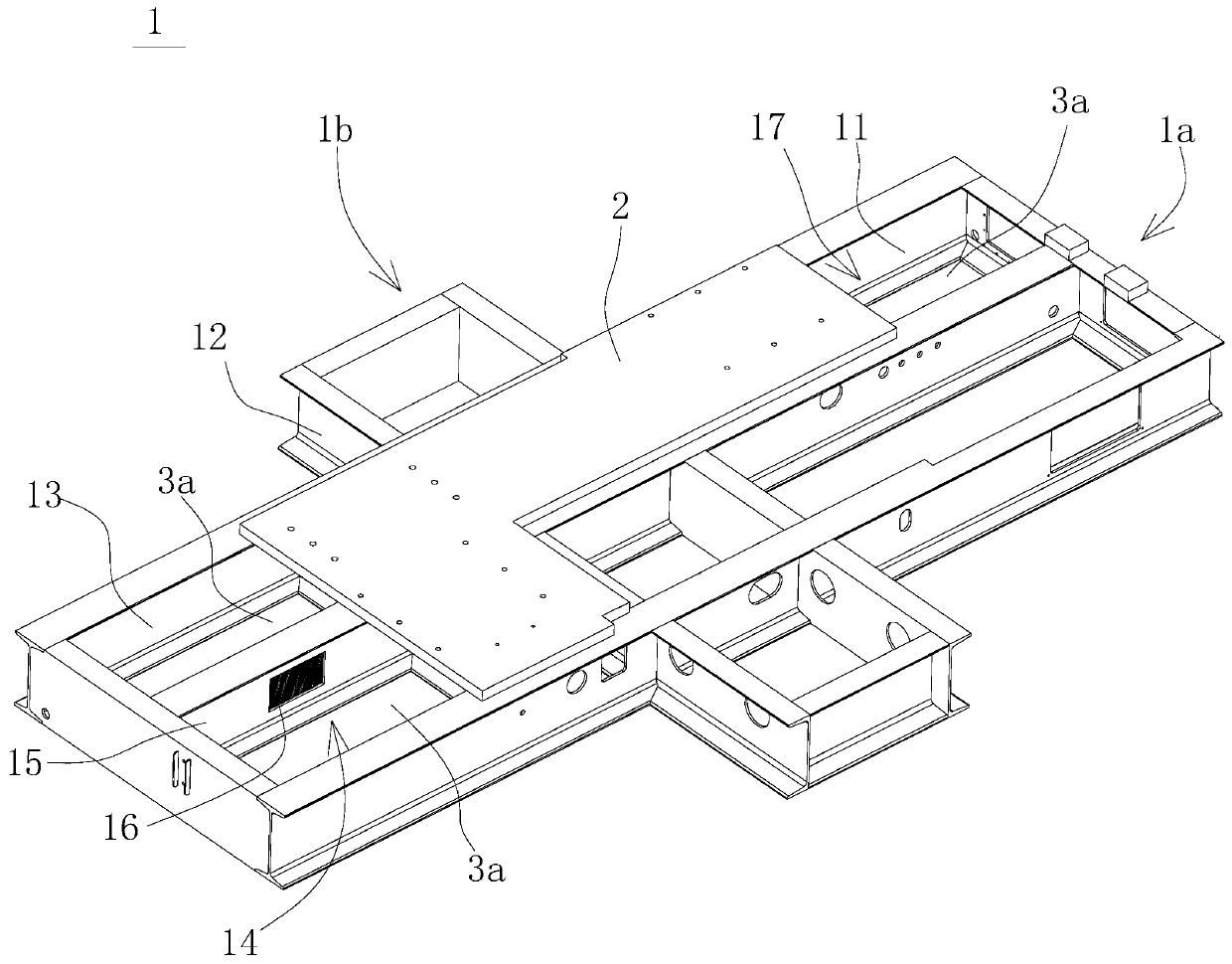

[0040] Refer to attached figure 2 , Step b: Weld a placement plate 2 on the upper surface of the bottom frame 1 correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com