A kind of magnetic phenylphosphine palladium composite catalyst and its application

A composite catalyst, phenylphosphine technology, applied in the direction of organic compound/hydride/coordination complex catalyst, physical/chemical process catalyst, organic chemistry, etc. Good catalytic effect and the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

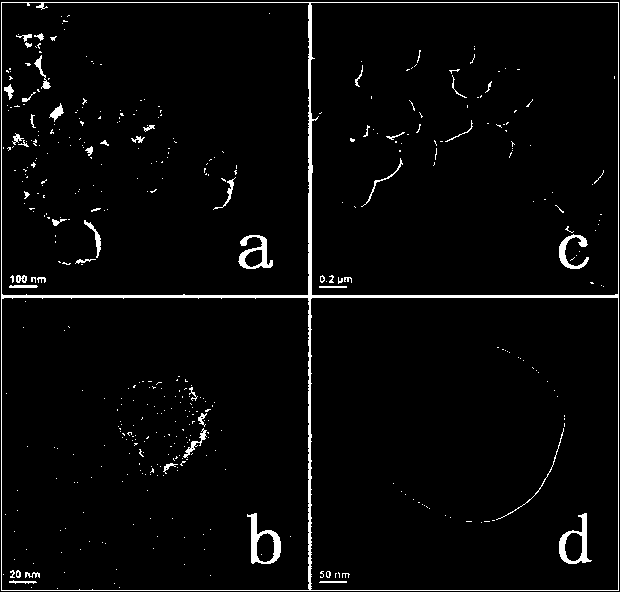

Image

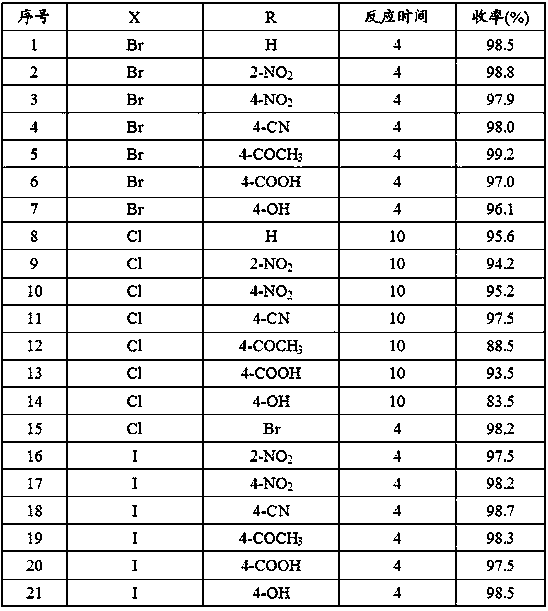

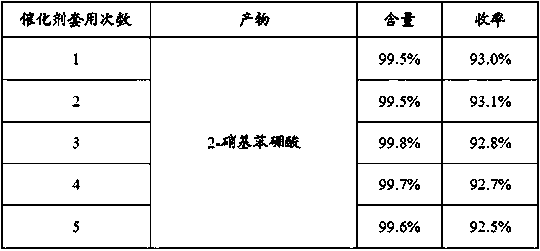

Examples

Embodiment 1

[0041] Provide a kind of magnetic phenylphosphine palladium composite catalyst, described magnetic phenylphosphine palladium composite catalyst is based on superparamagnetic Fe 3 O 4 @SiO 2 Nanospheres as a carrier, Fe 3 O 4 @SiO 2 The surface of the nanometer microsphere is covalently modified with diphenylphosphine palladium (II), and the structural formula of the magnetic phenylphosphine palladium composite catalyst is:

[0042] .

[0043] The preparation process of above-mentioned magnetic phenylphosphine palladium composite catalyst is as follows:

[0044] (1) Under nitrogen protection, add 2.00g of ferrous chloride tetrahydrate, 2.44g of ferric chloride, and 80mL of deionized water into a 250mL four-neck flask in sequence. Heat to 40 °C, add 9 mL of ammonia water dropwise, stir for 30 min, then raise the temperature to 85 °C, add 47 g of 15% sodium citrate aqueous solution and stir for 2 h to stop the reaction. After the temperature dropped to room temperature, ...

Embodiment 2

[0049] The difference between this embodiment and the specific example 1 is that the amount of tetraethoxysilicone added in step (2) is 1-10 mL. Other steps and implementation are the same as in the first embodiment.

Embodiment 3

[0051] The difference between this embodiment and specific examples 1 and 2 is that palladium acetate is added in step (4). Other steps and implementation methods are the same as those in the first and second specific examples.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com