Gear-rack driven hole sowing and seed discharging mechanism for seed discharger with hole wheel

A technology of rack and pinion and seed metering mechanism, applied in the field of agricultural machinery, can solve the problems such as difficulty in guaranteeing the quality of hole seeding, restriction, and soiling of the hole forming mechanism.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

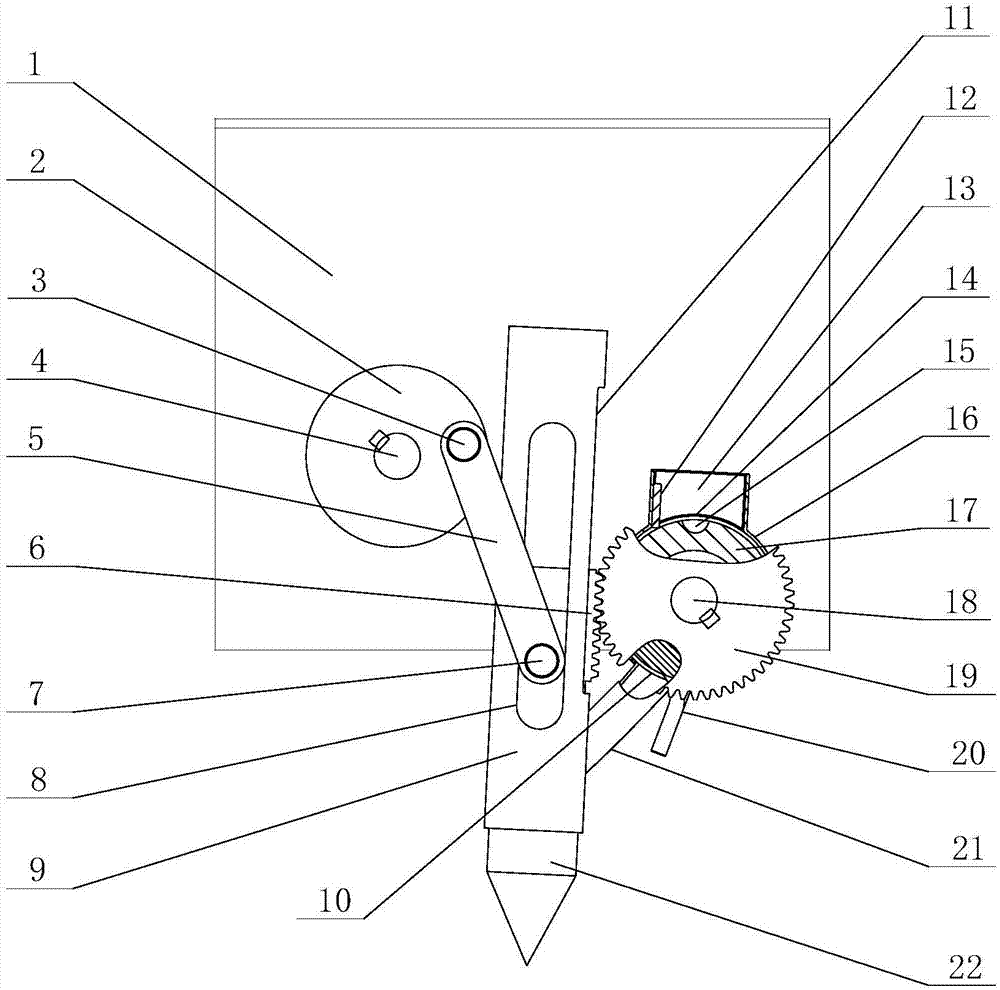

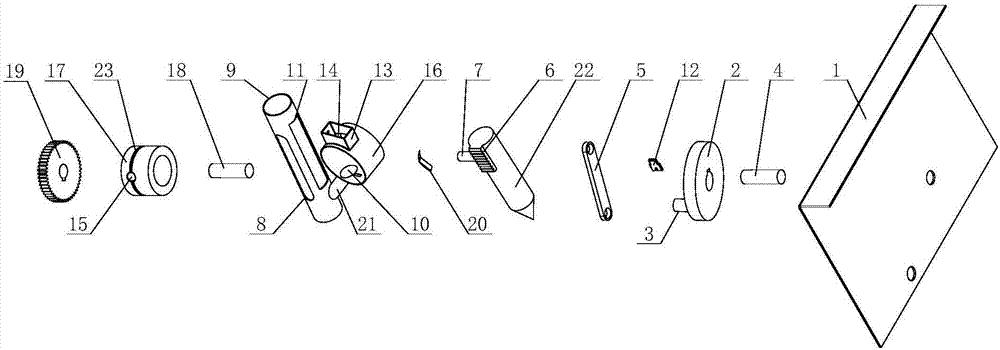

[0010] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A rack-and-pinion driven hole sowing and seeding mechanism of a hole wheel seed metering device includes a hole-piercing piston cylinder 9, and the hole-piercing piston 22 can move up and down and is fitted in the cavity of the hole-piercing piston cylinder 9. 9. There is a piston pin vertical running gap 8 on the cylinder wall, and the piston pin 7 can be moved up and down to be mated in the vertical running gap 8 of the piston pin. The hole piston barrel 9 is fixedly mounted on the fixed frame 1, and a rack vertical running gap 11 is provided on the wall of the hole piercing piston barrel 9, and the rack 6 can be moved up and down and mated in the vertical running gap 11 of the rack. , the rack 6 is fixedly integrated with the hole piercing piston 22, and the drive shaft 4 and the seed filling and discharging mechanism are respectively equipped with dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com