Master box flatness high efficiency detection equipment for computer technology development

A technology for testing equipment and the main box, which is applied in the direction of mechanical roughness/irregularity measurement, etc., and can solve problems such as time-consuming, laborious, low efficiency, and incomplete testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

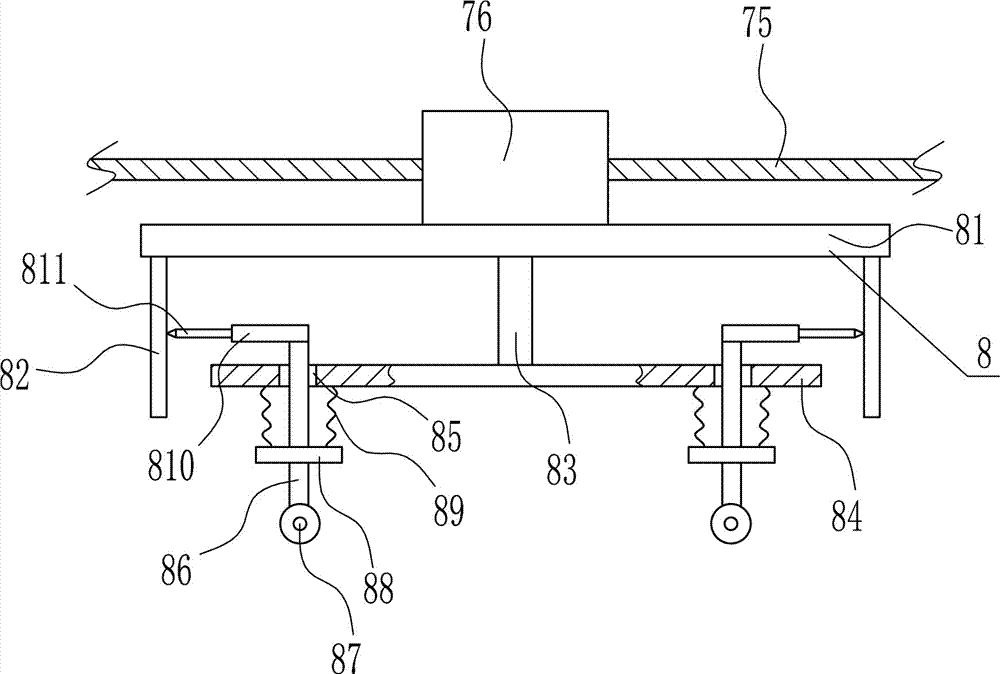

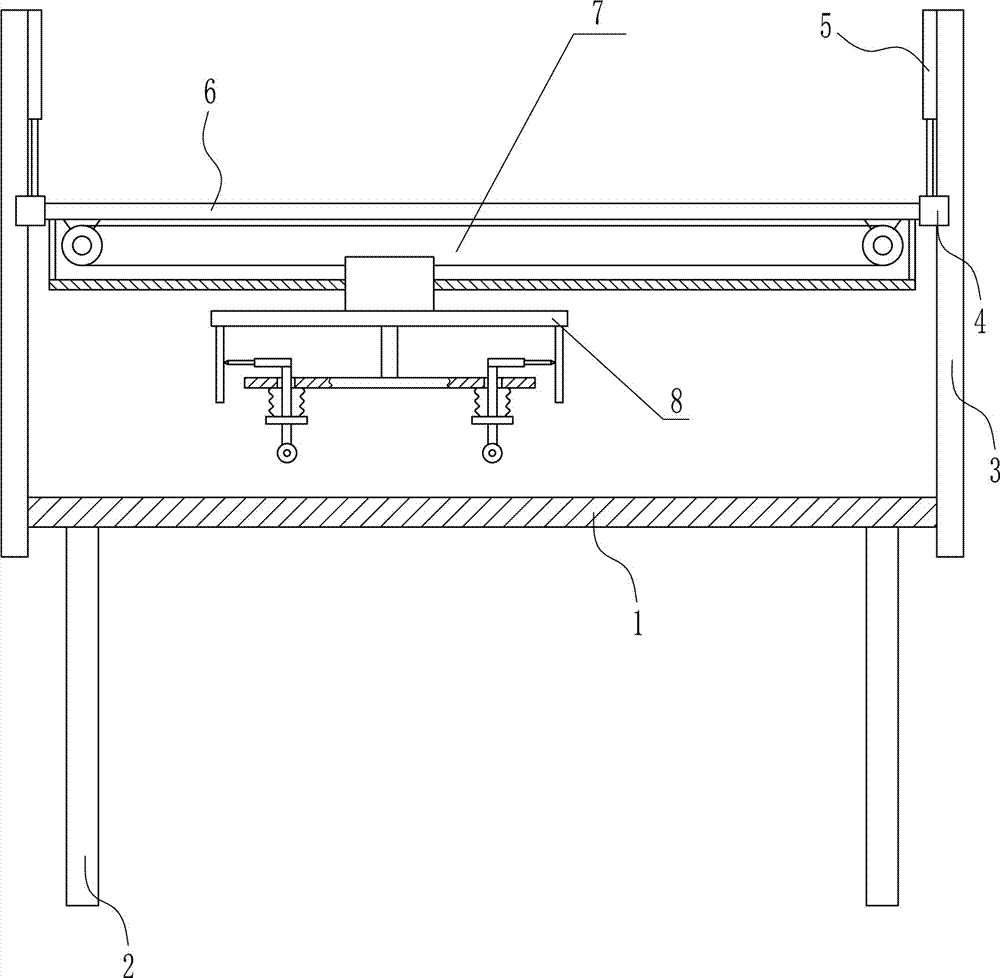

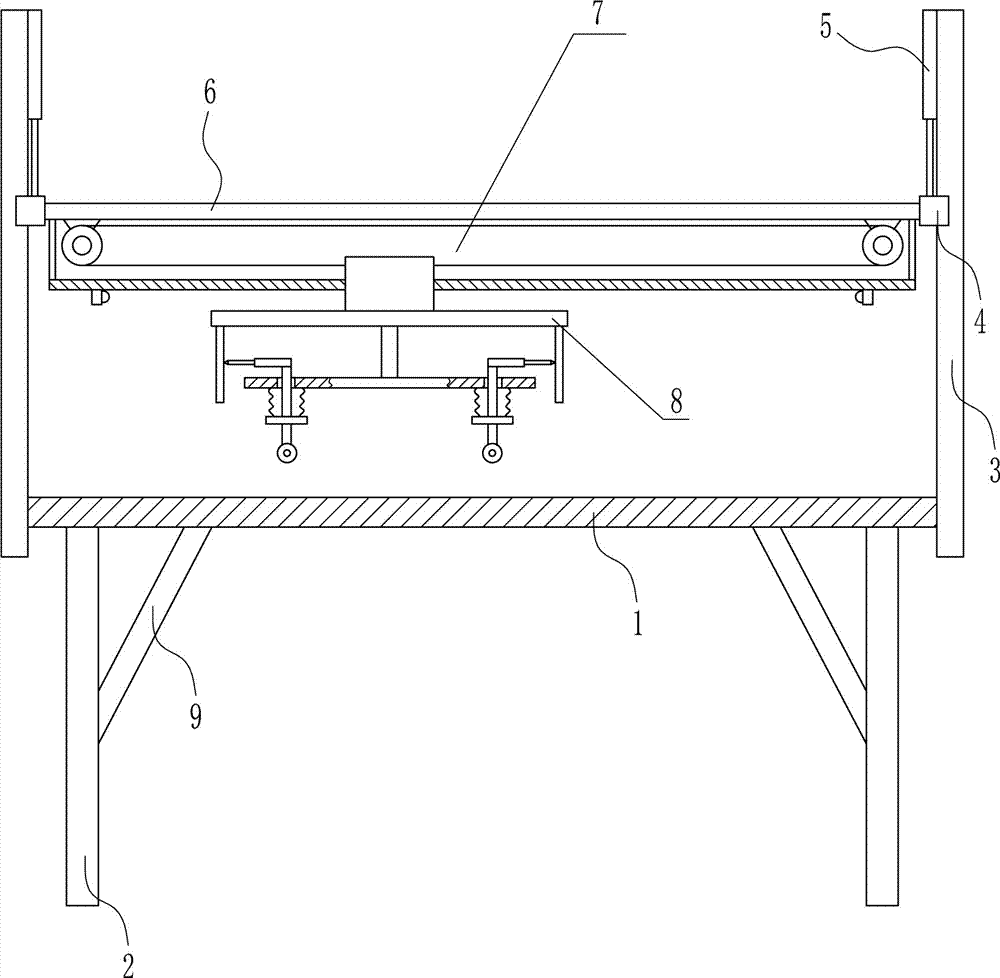

[0039] A high-efficiency detection device for the flatness of the main chassis used in the development of computer technology, such as Figure 1-10 As shown, it includes a top plate 1, a support plate 2, a slide rail 3, a slider 4, a first cylinder 5, a first horizontal plate 6, a left and right moving device 7 and a detection device 8. A support plate 2 is installed at the bottom of the top plate 1, and the top plate 1. Both the left side and the right side are connected by bolts to install the slide rail 3. The slide rail 3 is arranged vertically. The first cylinder 5 is installed in the connection mode, and the first cylinder 5 is vertically arranged. The slide rail 3 is provided with a slide block 4 that cooperates with it. The slide block 4 is slidingly matched with the slide rail 3. Below, the top of the slider 4 is connected to the telescopic rod of the first cylinder 5 through bolt connection, and the first horizontal plate 6 is installed between the left slider 4 and ...

Embodiment 2

[0041] A high-efficiency detection device for the flatness of the main chassis used in the development of computer technology, such as Figure 1-10 As shown, it includes a top plate 1, a support plate 2, a slide rail 3, a slider 4, a first cylinder 5, a first horizontal plate 6, a left and right moving device 7 and a detection device 8. A support plate 2 is installed at the bottom of the top plate 1, and the top plate 1. Both the left side and the right side are connected by bolts to install the slide rail 3. The slide rail 3 is arranged vertically. The first cylinder 5 is installed in the connection mode, and the first cylinder 5 is vertically arranged. The slide rail 3 is provided with a slide block 4 that cooperates with it. The slide block 4 is slidingly matched with the slide rail 3. Below, the top of the slider 4 is connected to the telescopic rod of the first cylinder 5 through bolt connection, and the first horizontal plate 6 is installed between the left slider 4 and ...

Embodiment 3

[0044] A high-efficiency detection device for the flatness of the main chassis used in the development of computer technology, such as Figure 1-10 As shown, it includes a top plate 1, a support plate 2, a slide rail 3, a slider 4, a first cylinder 5, a first horizontal plate 6, a left and right moving device 7 and a detection device 8. A support plate 2 is installed at the bottom of the top plate 1, and the top plate 1. Both the left side and the right side are connected by bolts to install the slide rail 3. The slide rail 3 is arranged vertically. The first cylinder 5 is installed in the connection mode, and the first cylinder 5 is vertically arranged. The slide rail 3 is provided with a slide block 4 that cooperates with it. The slide block 4 is slidingly matched with the slide rail 3. Below, the top of the slider 4 is connected to the telescopic rod of the first cylinder 5 through bolt connection, and the first horizontal plate 6 is installed between the left slider 4 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com