Automatic plate discharging device of stripping machine

A technology of plate ejection device and stripping machine, which is applied to conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of unstable turning angle, vulnerable plates, damaged plates, etc., so as to reduce the conveying efficiency and achieve no Manual automatic operation, the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

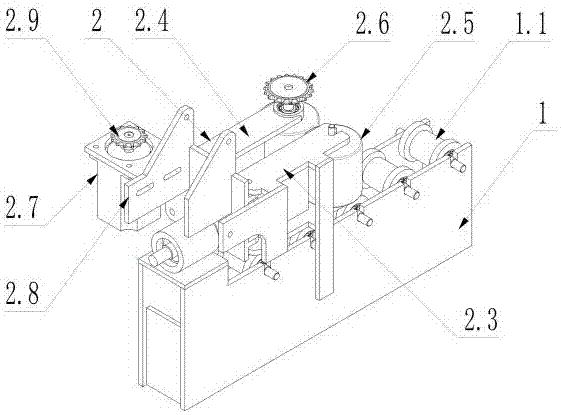

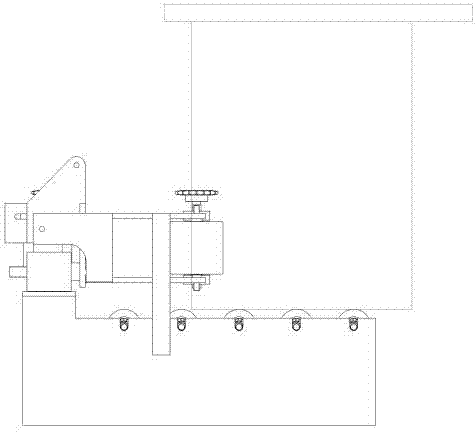

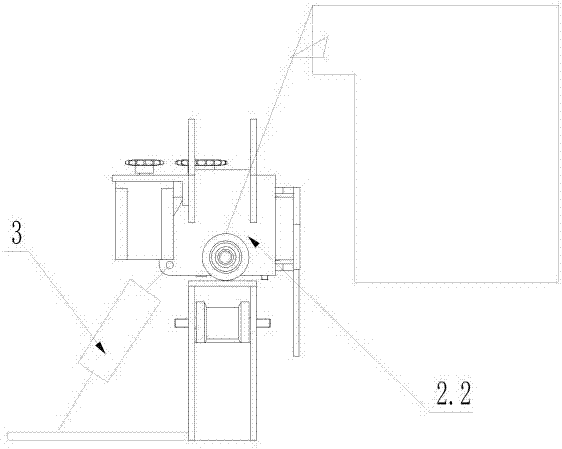

[0015] Embodiment 1: An automatic stripping device of a peeling machine, including a strip-shaped bottom stripping slot 1, several parallel stripping rollers 1.1 arranged horizontally in the bottom stripping slot 1 and arranged above the bottom stripping slot plate 1 The pole plate clamping device 2, the pole plate clamping device 2 includes a vertical mounting plate 2.1, a rotating device 2.2 connected with the vertical mounting plate 2.1 to drive the vertical mounting plate 2.1 to turn over, and a vertical fixed connection with the vertical mounting plate 2.1 The fixed clamping arm 2.3, the movable clamping arm 2.4 symmetrical to the fixed clamping arm 2.3, the rotating device 2.2 includes the bearing sleeve 2.2.1 connected to the front end of the bottom outlet plate slot 1, the bearing in the bearing sleeve 2.2.1, and inserted into the bearing The rotating shaft 2.2.2, the rotating shaft 2.2.2 is fixedly connected with the vertical mounting plate 2.1, drives the vertical mou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com