Powder energizing device

An energizing and powder technology, applied in the field of energizing devices and powder energizing devices, can solve the problems of multiple particle sizes, no human control, and no industrial standardization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

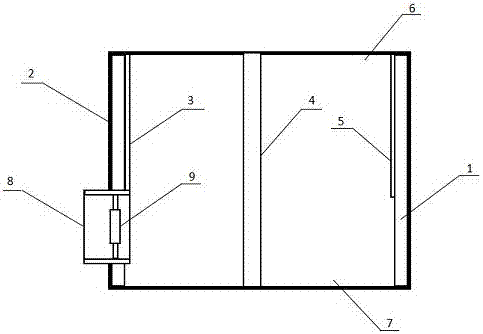

[0016] A powder energizing device, comprising a barrel-shaped casing 1 as an auxiliary electrode, the barrel-shaped casing 1 is wrapped with an insulating layer 2, and a conductive layer 3 is attached to the left side of the barrel-shaped casing 1; A main electrode 4 is provided in the middle of the casing 1, and a loop electrode 5 is attached to the right side inside the barrel-shaped casing 1, and an air outlet 6 and an air inlet blowing port 7 are respectively provided at the upper end and the lower end of the barrel-shaped casing 1.

[0017] In the present invention, the diameter of the preferred barrel-shaped casing 1 is 10-1000000000mm, and the length of the preferred barrel-shaped casing 1 is 10-100000000mm; meanwhile, in practical application, the length of the main electrode 4 is 1 / 1 of the barrel-shaped casing 1 10--1 / 5, the length of the main electrode 4 is 10-100000000mm, the number of the main electrode 4 is one or more than one, and less than ten. If the barrel-sh...

Embodiment 2

[0024] Barrel Energizer:

[0025] A, the barrel-shaped shell 1 is the auxiliary electrode, the diameter of the barrel is 10-1000000000mm, the shape of the end face of the barrel can be various geometric shapes, the length of the shell barrel is 10-100000000mm; the material of the barrel is all metal plates or meshes, and can also be The barrel outer layer is an insulator material, the barrel inner layer material is any conductive metal plate or net, and the material of the return electrode 5 can also be an inorganic conductive material, such as carbon fiber.

[0026] B, barrel center, main electrode 4, 1 / 10--1 / 5 shorter than the barrel, insulated from the loop electrode of the barrel shell, the diameter of the main electrode is 0.01-1000 mm smaller than the barrel, and the length is 10-100000000mm. When the diameter of the barrel is large, multiple main electrodes can be set; the main electrode material can be any conductive metal, or an inorganic conductive material, such as ...

Embodiment 3

[0031] When the concentration of harmful dust and harmful gas in the aerosol source is relatively large, the barrel energizer can be set to several levels until the concentration of harmful dust and harmful gas reaches the standard for harmless discharge.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com