Preparation method of pineapple extract for cigarettes

A technology of pineapple extract and pineapple, which is applied in the field of preparation of pineapple extract for tobacco, can solve the problems such as unreported pineapple extract for tobacco, and achieve the effects of facilitating industrial production transformation, enriching tobacco flavor, and easy production transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

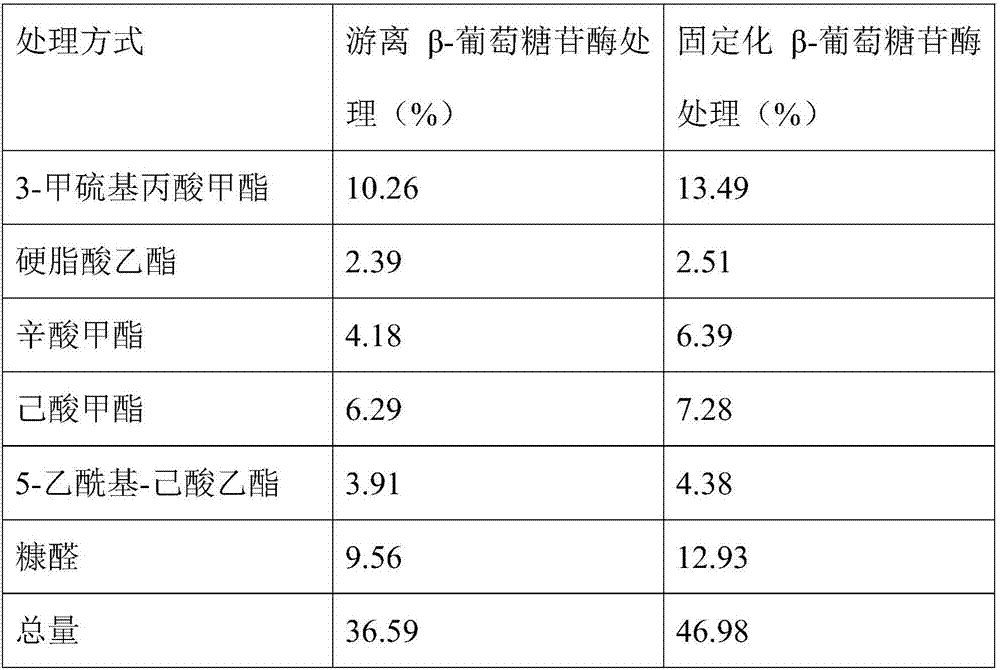

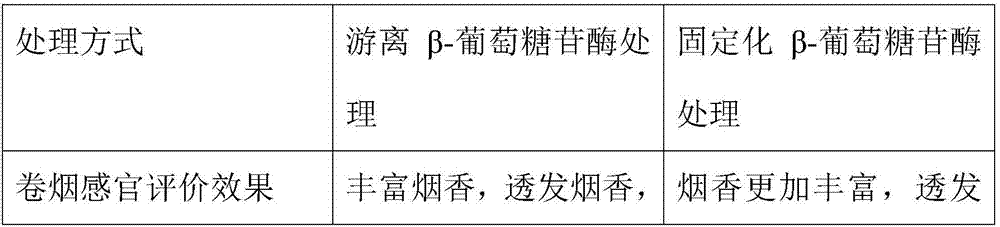

Examples

Embodiment 1

[0018] (1) Wash the pineapple, remove the skin, put it into a cold press for cold pressing, and take out the juice to obtain pineapple juice;

[0019] (2) Dissolve 0.2g of solid β-glucosidase in 1mL of citric acid buffer (0.1mol / L, pH4.5), add 18mL of sodium alginate solution with a mass concentration of 2%, stir well, and then add 26mL Calcium chloride solution with a mass concentration of 2%, embedded at 4°C for 1.5h, and washed with buffer solution to obtain sodium alginate-immobilized enzyme with a loading capacity of 15U / g;

[0020] (3) Take immobilized β-glucosidase to treat pineapple juice, the solid dosage of immobilized β-glucosidase is 13g / L, the pH value of enzyme treatment is 3~4, the enzyme treatment temperature is 36°C, and the enzyme treatment time is 2.5h. After completion, settle at 3°C for 48 hours;

[0021] (4) Filter the extract after enzyme treatment with filter paper to remove large particles of impurities to obtain a clarified pineapple extract, and c...

Embodiment 2

[0024] (1) Wash the pineapple, remove the skin, put it into a cold press for cold pressing, and take out the juice to obtain pineapple juice;

[0025] (2) Dissolve 0.15g of solid β-glucosidase in 1mL of citric acid buffer (0.1mol / L, pH4.5), add 15mL of sodium alginate solution with a mass concentration of 2%, stir well, and then add 20mL The calcium chloride solution with a mass concentration of 2% was embedded at 4° C. for 2 hours, and then washed with a buffer solution to obtain immobilized β-glucosidase with a loading capacity of 10 U / g.

[0026] (3) Treat pineapple juice with immobilized β-glucosidase, the solid dosage of immobilized β-glucosidase is 16g / L, the pH value of enzyme treatment is 4~5, the temperature of enzyme treatment is 38°C, the treatment time of enzyme is 3h, and the treatment is completed Then settle at 4°C for 55 hours;

[0027] (4) Filter the extract after the enzyme treatment to remove large particles of impurities to obtain a clarified pineapple ext...

Embodiment 3

[0030] (1) Wash the pineapple, remove the skin, put it into a cold press for cold pressing, and take out the juice to obtain pineapple juice;

[0031] (2) Dissolve 0.3g of solid β-glucosidase in 1mL of citric acid buffer (0.1mol / L, pH4.5), add 20mL of sodium alginate solution with a mass concentration of 2%, stir well, and then add 30mL Calcium chloride solution with a mass concentration of 2%, embedded at 4°C for 3 hours, and washed with buffer solution to obtain immobilized β-glucosidase with a loading capacity of 20 U / g.

[0032] (3) Take immobilized β-glucosidase to treat pineapple juice, the solid dosage of immobilized β-glucosidase is 20 / L, the pH value of enzyme treatment is 5-6, the temperature of enzyme treatment is 40°C, the time of enzyme treatment is 5h, and the treatment is completed Then settle at 3°C for 58 hours;

[0033] (4) Filter the extract after enzyme treatment to remove large particles of impurities to obtain a clarified pineapple extract, concentrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com