Engine dismounting video observation device

An observation device and engine technology, applied in the direction of TV, color TV, closed-circuit television system, etc., can solve the problems of inconvenient use and operation, narrow space gap, low application efficiency, etc., to improve the degree of automation and reliability, and the degree of automation High, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

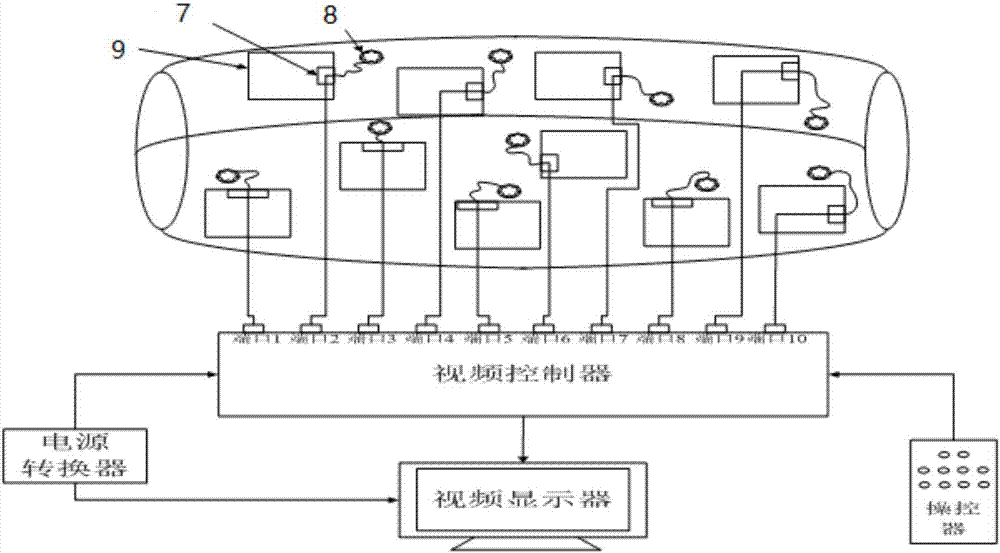

[0020] The observation device is composed of a video unit, a mounting clip, a video controller, a video display, a manipulator, a power converter, etc., wherein the video unit includes an LED light source, a video head, a flexible bending rod, a data line, and a power line. Arrange 10 video units at the observation port of the engine installation cabin, and fix the video units with mounting clips for effective installation. At the same time, connect the power line and data line of each video unit with the port 1 to port 10 of the video controller. Make electrical connections, and at the same time connect the video controller with the power converter, video display, and controller to form an overall structure to achieve effective observation of the system.

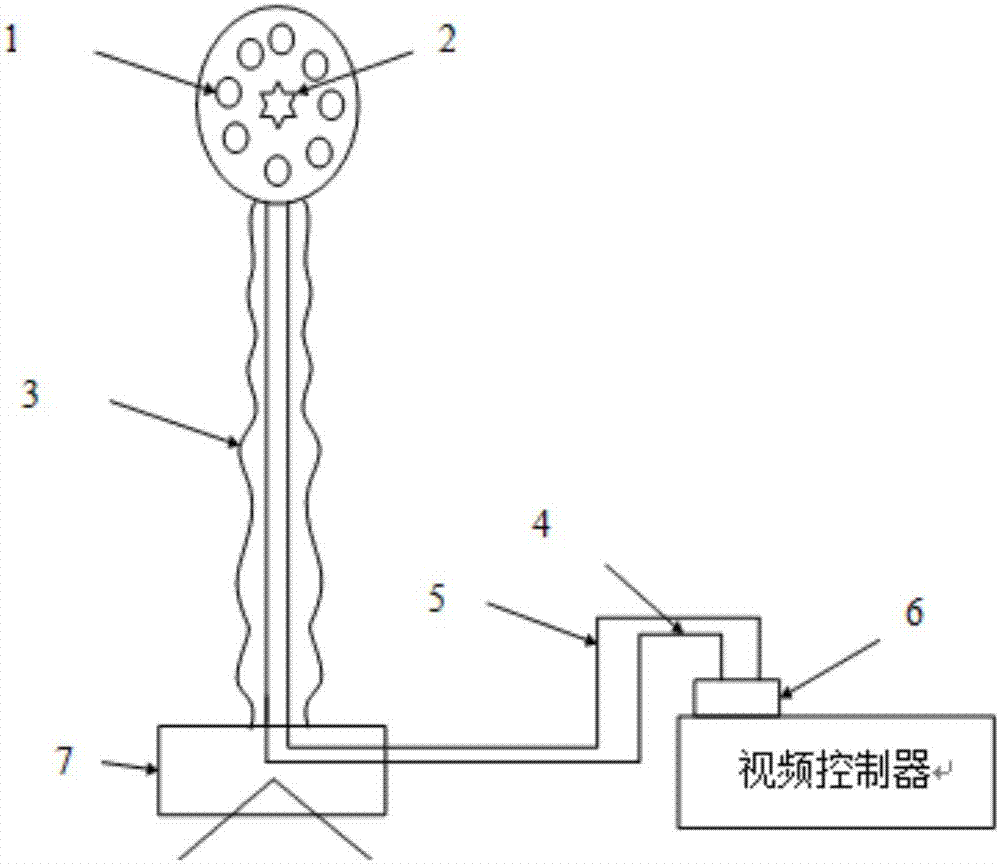

[0021] As the information collection of the observation device and the input of video information, the video unit is composed of a video head, LED light source, flexible bending rod, power line, and data line light. The vide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com