Ceramic adapter plate used for mounting large-size ceramic tube shell

A ceramic tube-shell, large-scale technology, applied in electrical components, electrical solid devices, circuits, etc., can solve problems affecting device reliability, fatigue, solder joint failure, etc., to reduce thermal expansion coefficient mismatch, reduce loss, The effect of reducing the installation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

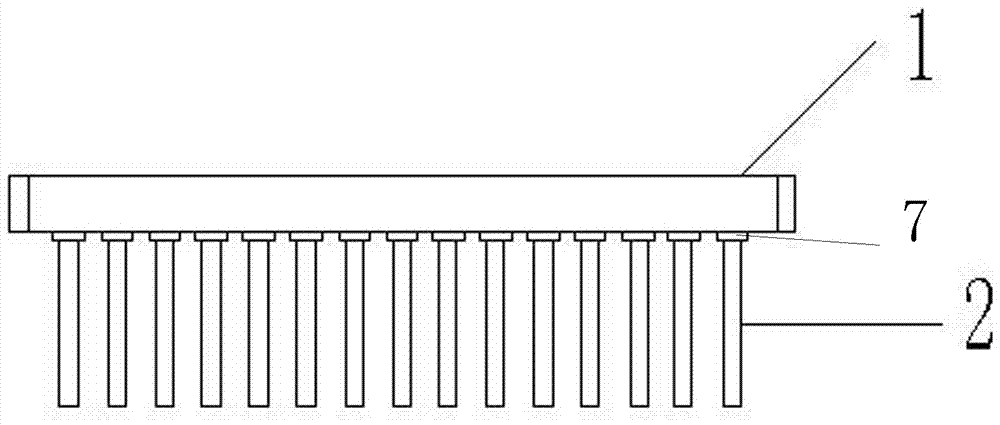

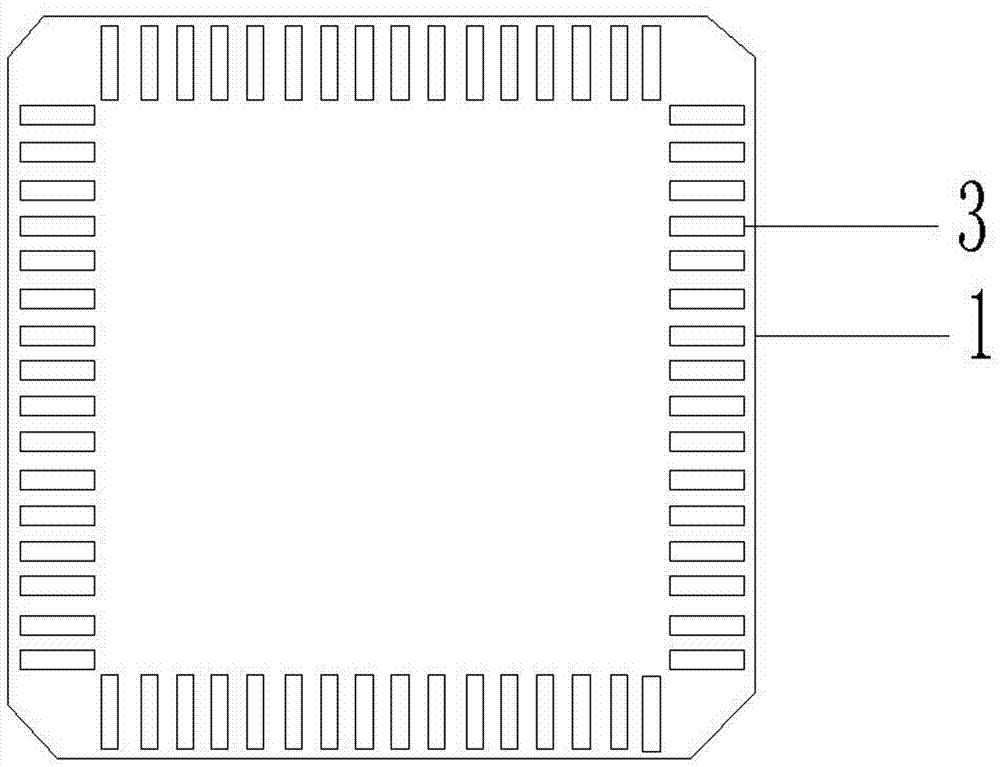

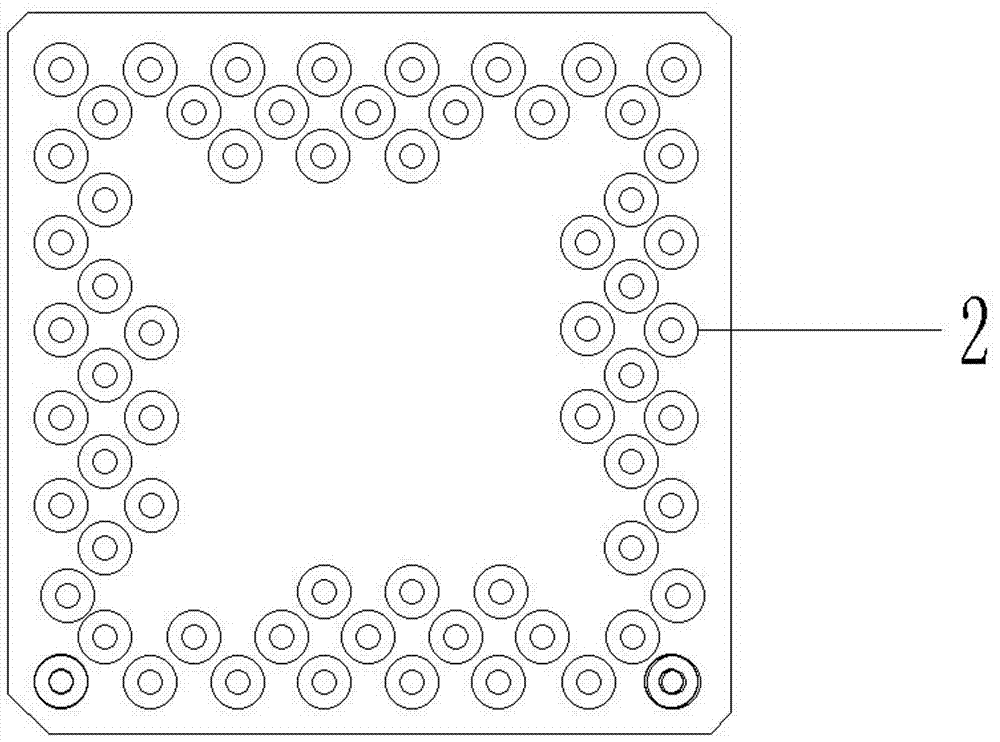

[0018] The present invention provides a Figure 1 to Figure 3 The shown ceramic adapter plate for installation of large-size ceramic tube shells includes a ceramic substrate 1, a metal conduction layer is arranged on the front of the ceramic substrate 1, and the back of the ceramic substrate 1 is provided with such figure 1 As shown in the metal pin lead 2, the metal pin lead 2 communicates with the metal conduction layer. Its installation structure is as Figure 4 As shown, through the ceramic substrate 1 with pin grid array pin leads, the pin leads are used as a buffer structure for stress buffering to release the stress between the ceramic package 5 and the PCB board 4, which can effectively reduce the thermal expansion coefficient mismatch. At the same time, the lead-out method of pins and wires can effectively shorten the signa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com