Instrument positioning method applicable to substation patrol inspection robot

An inspection robot and positioning method technology, applied in the field of image recognition, can solve problems such as inability to locate instruments, reducing system scalability, and failure of affine transformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

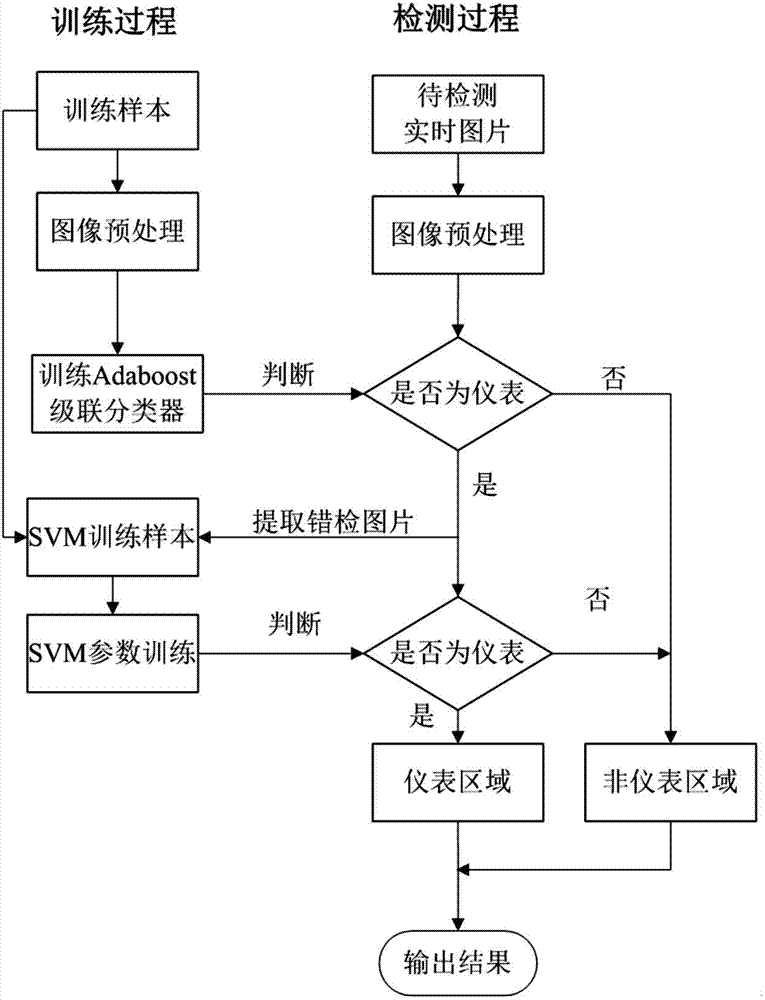

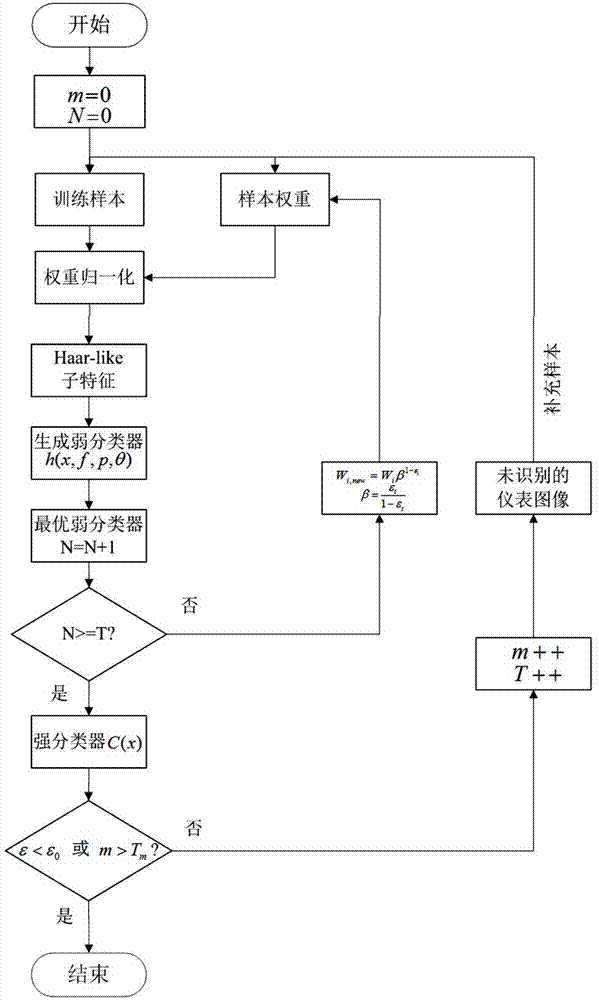

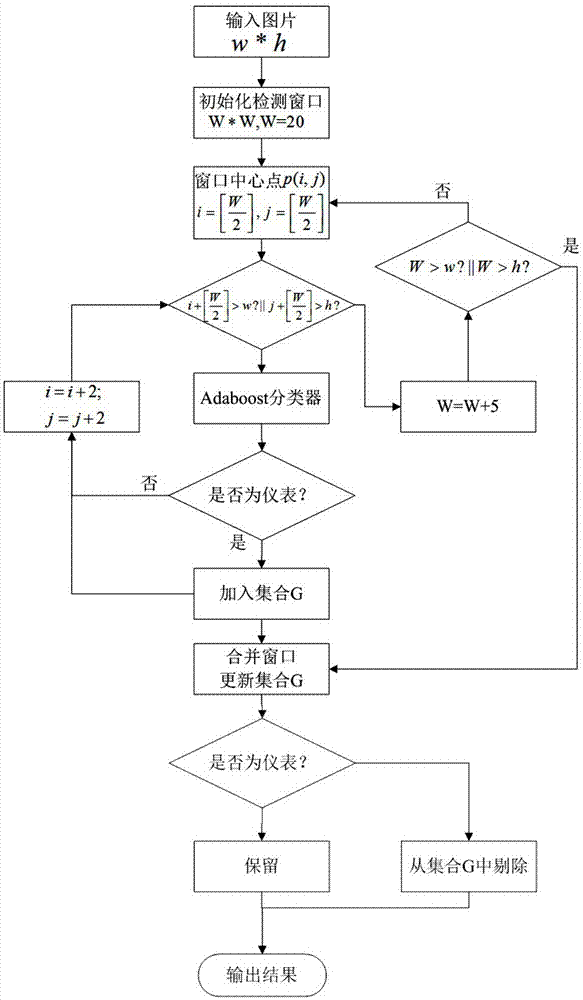

[0054] See attached picture. In this embodiment, an Adaboost classifier and an SVM classifier are used to form a two-stage instrument location system for instrument location. First, in order to train the Adaboost classifier, a large number of samples need to be collected, including positive sample images containing only the dashboard and negative sample images containing only the background. Then, in order to reduce the probability of instrument missed detection, a higher detection rate is set, and these samples are used to train an Adaboost classifier with a high detection rate; the training process includes feature selection, weak classifier training, strong classifier training. The image to be processed uses this classifier with a high detection rate to detect the instrument once, and can locate one or more instrument areas; use the SVM-based binary classifier as the classifier for the secondary detection, and perform secondary detection on the candidate area Detect and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com