Wireless monitoring and debugging platform for lithium battery pole piece rolling mill equipment based on labview and wifi

A lithium battery and rolling mill technology, applied in computer control, control/adjustment system, program control, etc., can solve the problems of reduced work efficiency, long distance from the laboratory, and delay in time, so as to improve industry competitiveness, ensure production efficiency, Responsive and timely effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further explained below in conjunction with the embodiments and accompanying drawings, but this should not be used as a limitation to the protection scope of the claims of the present application.

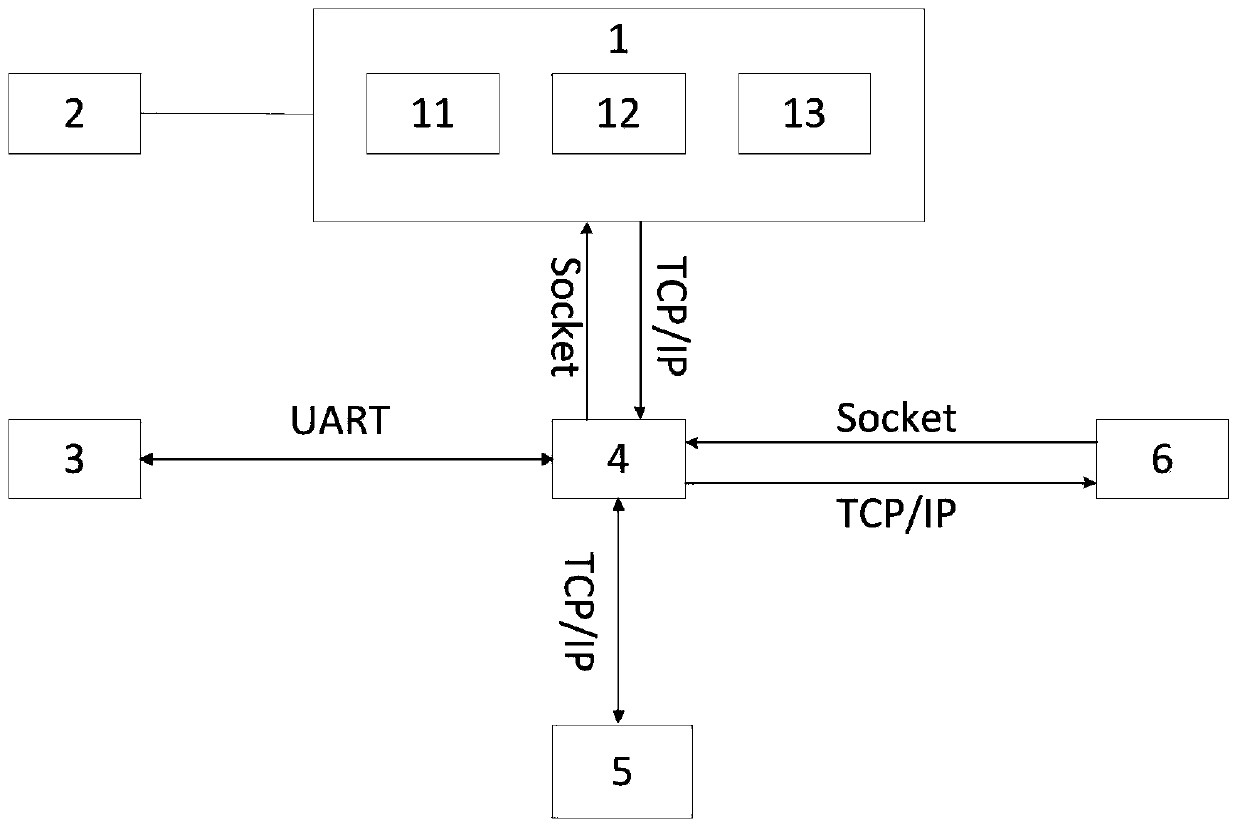

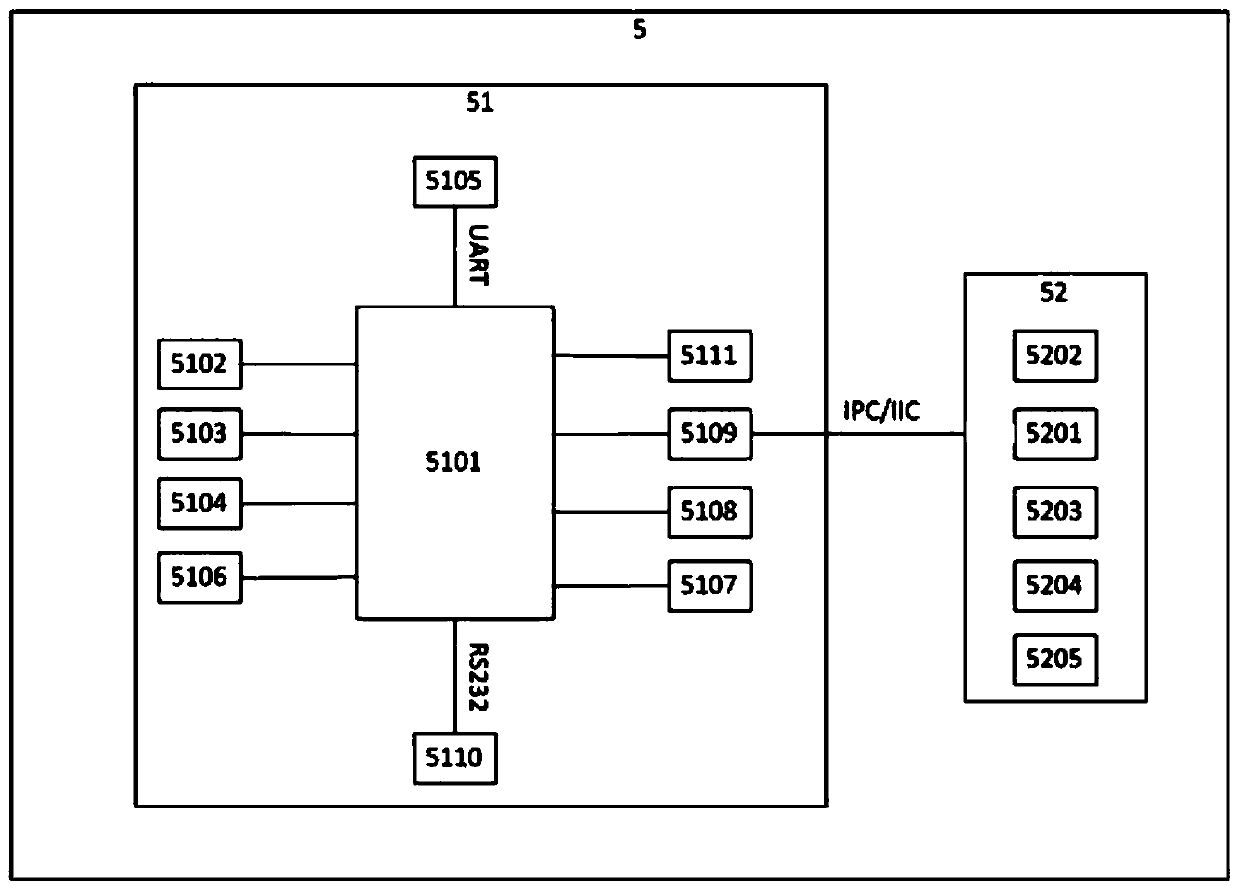

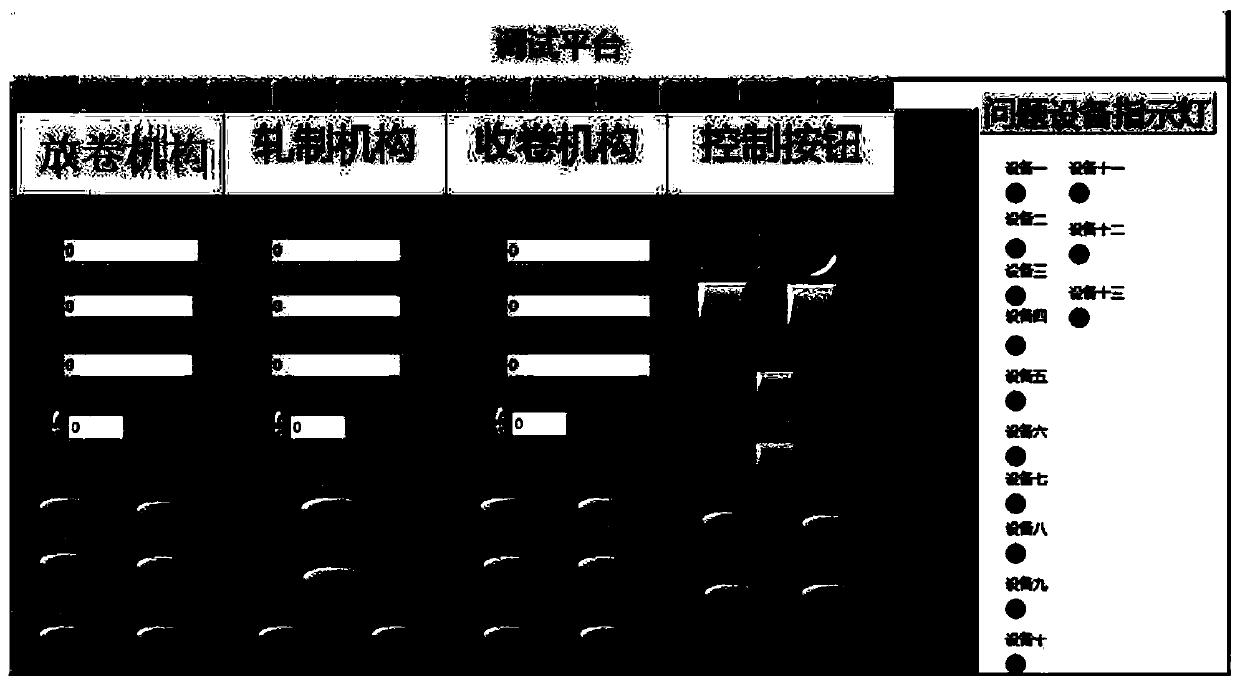

[0018] The present invention is based on Labview and WiFi wireless monitoring and debugging platform for lithium battery pole piece rolling mill equipment (referred to as debugging platform, see figure 1 ) includes a display interface 1, a power supply module 2, a wifi module 3 and a platform data transmission control module 4; the display interface is connected with the platform data transmission control module 4, and the power supply module 2 supplies power for the entire debugging platform, and the debugging platform is passed through the wifi module 3 Connect with the lithium battery pole piece rolling mill controller 5 and the external cloud server 6; the lithium battery pole piece rolling mill controller 5 has a rolling mill wireless networ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com