Negative pressure conveying type dredging robot

A conveying and robotic technology, applied in earth movers/shovels, mechanically driven excavators/dredgers, construction, etc., can solve problems such as poor cleaning effect and low efficiency, improve cleaning ability, eliminate cleaning Dead angle, reduce the effect of manual work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

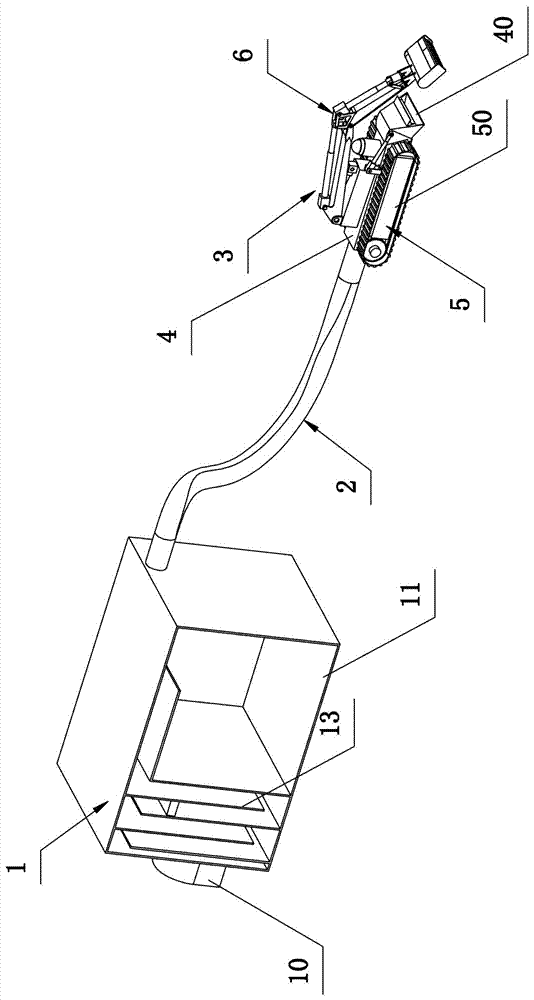

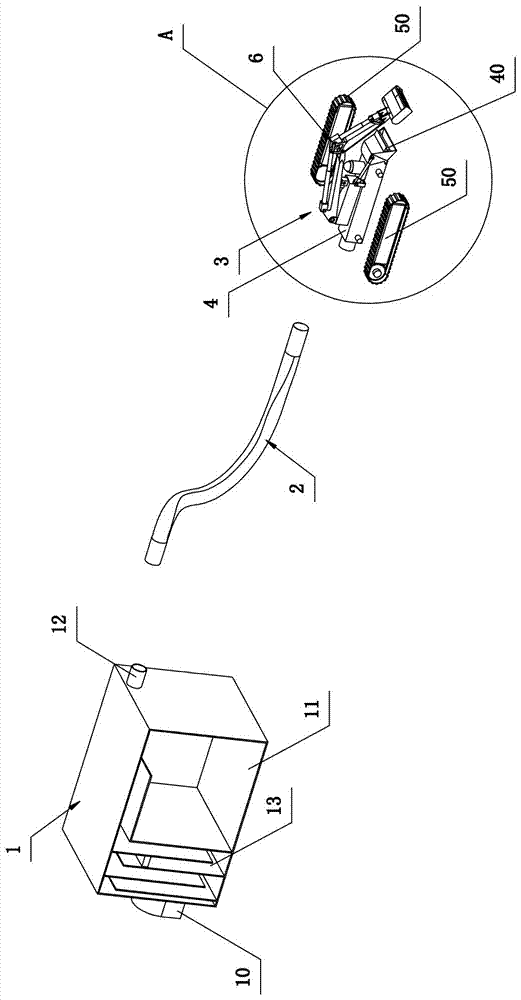

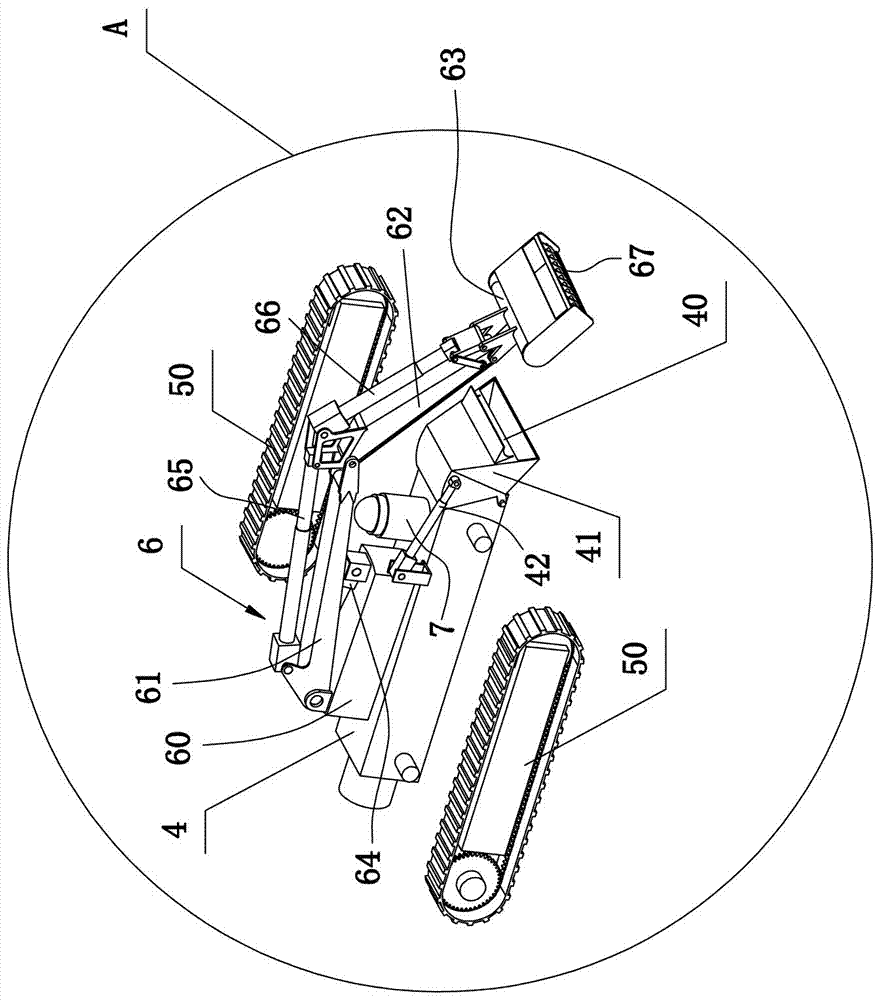

[0025] refer to figure 1 , figure 2 and image 3 . A negative pressure conveying type dredging robot, including a negative pressure suction device 1, a suction and discharge pipe 2, and a working robot mechanism 3, the working robot mechanism 3 includes a silt collection bin 4 through which the middle part is connected, and is used to drive the silt collection bin 4. 4 The moving mechanism 5 is displaced, the front end of the sludge collection bin 4 is provided with an auxiliary suction port 40, the rear end of the sludge collection bin 4 communicates with one end of the suction and discharge pipe 2, and the suction and discharge pipe 2 The other end communicates with the negative pressure suction device 1 .

[0026] refer to figure 1 , figure 2 and image 3 . The silt collection bin 4 is arranged in a cuboid shape, and the running mechanism 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com