Waste cement concrete recycled aggregate warm mixed asphalt mixture and making method thereof

A technology of cement concrete and recycled aggregates, which is applied in the field of asphalt mixtures. It can solve the problems of decreased road performance of warm-mix asphalt mixtures, high energy consumption of hot-mix asphalt mixtures, waste of natural aggregates, etc., and reduce exhaust emissions. , Improve the comprehensive utilization rate, enhance the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This example is a waste cement concrete regenerated aggregate warm-mix asphalt mixture prepared according to the gradation requirements of continuous dense gradation with a nominal maximum particle size of 16 mm in "Technical Specifications for Road Asphalt Pavement Construction (JTG F40-2004)". Its raw materials are as follows:

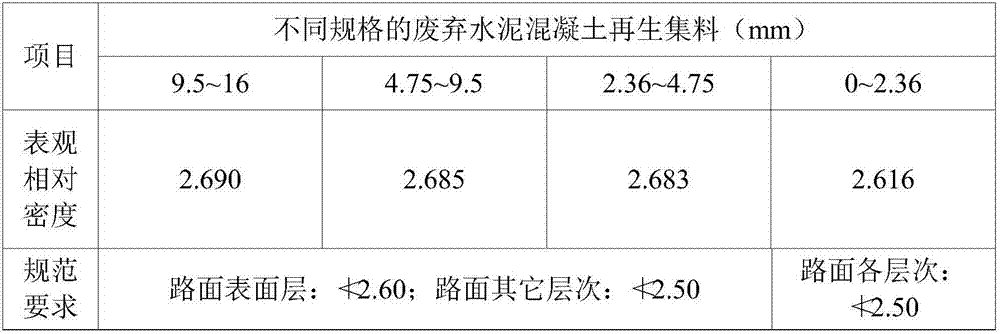

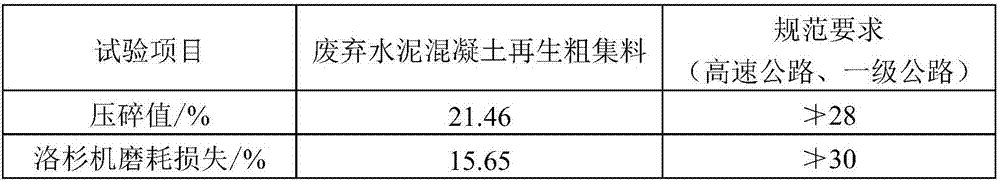

[0029] 1. In this embodiment, four grades of waste cement concrete recycled aggregates are selected: recycled aggregates with a particle size of 9.5-16 mm, recycled aggregates with a particle size of 4.75-9.5 mm, recycled aggregates with a particle size of 2.36-4.75 mm, The apparent relative density of recycled aggregates with a particle size of 0-2.36 mm is shown in Table 1. The apparent relative densities of recycled aggregates of waste cement concrete of each grade meet the "Technical Specifications for Construction of Highway Asphalt Pavement (JTG F40-2004) "Require. The test results of mechanical performance indicators such as crushing v...

Embodiment 2

[0043] This example is a waste cement concrete recycled aggregate warm-mix asphalt mixture prepared according to the continuous dense gradation with a nominal maximum particle size of 19 mm in the "Technical Specifications for Construction of Highway Asphalt Pavement (JTG F40-2004)". The waste cement concrete recycled aggregate warm mix asphalt mixture is the same as that of Example 1, only the particle size specification of the waste cement concrete recycled aggregate and the parts by weight of the raw materials used are different.

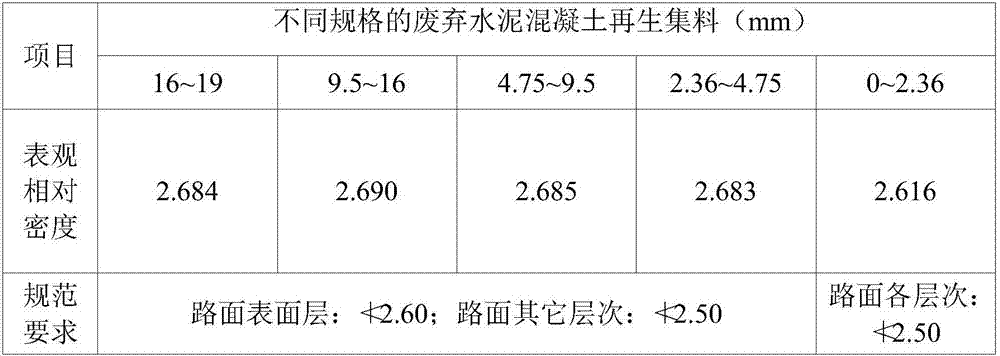

[0044] 1. In this embodiment, five grades of recycled aggregates for waste cement concrete are selected: recycled aggregates with a particle size of 16-19mm, recycled aggregates with a particle size of 9.5-16mm, recycled aggregates with a particle size of 4.75-9.5mm, granular The apparent relative densities of recycled aggregates with a diameter of 2.36-4.75 mm and recycled aggregates with a particle size of 0-2.36 mm are shown in Table 3. Asphal...

Embodiment 3

[0050] This example is a waste cement concrete recycled aggregate warm mix asphalt mixture prepared according to the continuous dense gradation with a nominal maximum particle size of 26.5mm in the "Technical Specifications for Construction of Highway Asphalt Pavement (JTG F40-2004)". The waste cement concrete regenerated aggregate warm-mix asphalt mixture of Example 1 is the same as that of Example 1, only the particle size specifications of the waste cement concrete regenerated aggregate and the weight parts of each raw material used are different.

[0051] 1. In this embodiment, six grades of waste cement concrete recycled aggregates are selected: recycled aggregates with a particle size of 19-26.5 mm, recycled aggregates with a particle size of 16-19 mm, recycled aggregates with a particle size of 9.5-16 mm, granular The apparent relative densities of recycled aggregates with a diameter of 4.75-9.5 mm, recycled aggregates with a particle size of 2.36-4.75 mm, and recycled a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com