Method and device of quality-orientated crystallization treatment on desulfurization waste water

A technology for desulfurization wastewater and crystallization treatment, which is applied in the direction of gaseous effluent wastewater treatment, dehydration/drying/thickened sludge treatment, multi-stage water treatment, etc. to avoid fouling of the membrane, increase water recovery rate, and save civil engineering costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] A desulfurization wastewater project, the treated water volume is 22t / h, influent water quality: pH: 7.16, total dissolved solids (TDS): 49750mg / L, Cl - : 20821.8mg / L, SO 4 2- : 3534.3mg / L, Mg 2+ : 6220mg / L, Ca 2+ : 1933mg / L, HCO 3 - : 60.556mg / L, chemical oxygen demand (COD): 944.68mg / L.

[0062] Treatment requirements: the effluent meets the cooling water standard of power plant auxiliary equipment: pH: 6-9, total dissolved solids (TDS) ≤ 1000mg / L, Cl - : ≤250mg / L, SO 4 2- : ≤250mg / L, total hardness (as CaCO 3 Total) ≤ 450mg / L, chemical oxygen demand (COD) ≤ 50mg / L, effluent reuse, salt separation, and zero discharge treatment of wastewater.

[0063] Selected process:

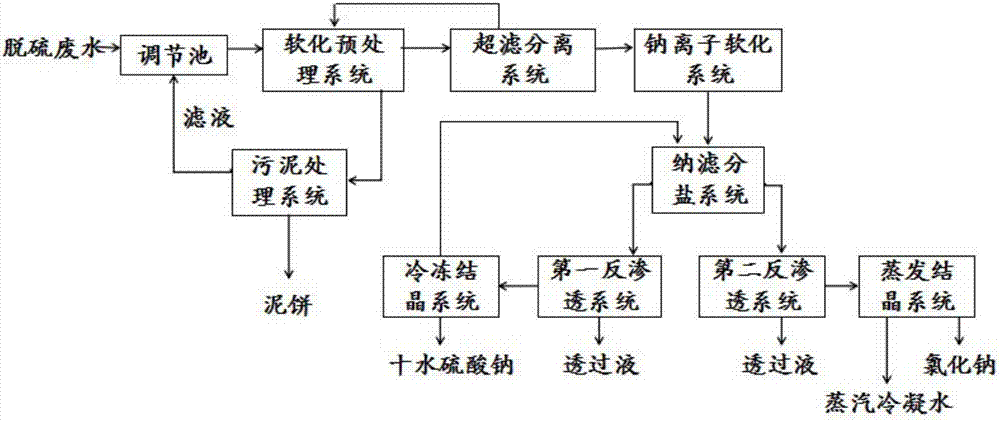

[0064] Softening pretreatment→ultrafiltration→sodium ion exchanger→dish tube nanofiltration salt separation→dish tube reverse osmosis→freezing crystallization and evaporation crystallization.

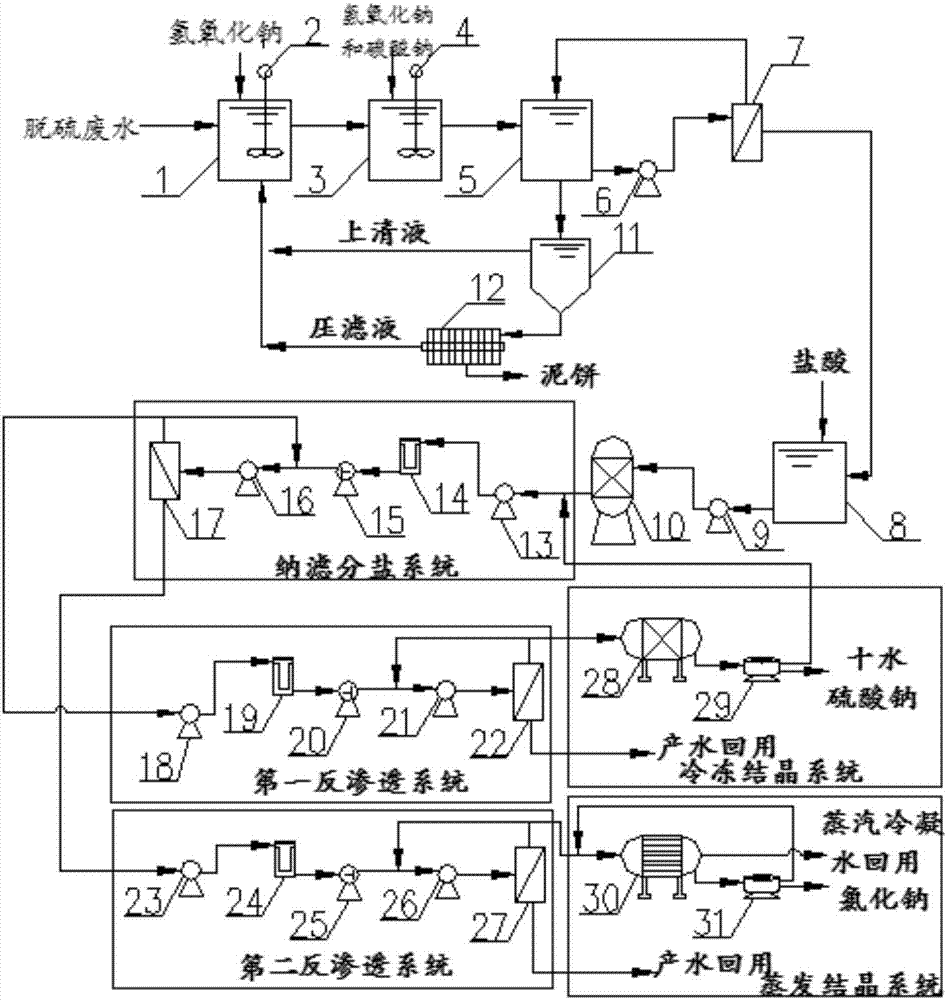

[0065] After the desulfurization wastewater is pre-sedimented in the regulating tank, it enters th...

Embodiment 2

[0072] For a desulfurization wastewater project, the treated water volume is 36t / h, the influent water quality: pH: 7.24, total dissolved solids (TDS): 35534.6mg / L, Cl - : 15000mg / L, SO 4 2- : 6000mg / L, Mg 2+ : 600mg / L, Ca 2+ : 2000mg / L, HCO 3 - : 65mg / L, chemical oxygen demand (COD): 95mg / L.

[0073] Treatment requirements: the effluent meets the power plant circulating cooling water standard: pH: 6-9, total dissolved solids (TDS) ≤ 1000mg / L, Cl - : ≤250mg / L, SO 4 2- : ≤250mg / L, total hardness (as CaCO 3 Total) ≤ 450mg / L, chemical oxygen demand (COD) ≤ 50mg / L, effluent reuse, salt separation, and zero discharge treatment of wastewater.

[0074] Selected process:

[0075] Softening pretreatment → ultrafiltration → sodium ion exchanger → nanofiltration salt separation → reverse osmosis → freeze crystallization and evaporation crystallization.

[0076] After the desulfurization wastewater is pre-sedimented in the regulating tank, it enters the first reaction tank 1, a...

Embodiment 3

[0083] For a desulfurization wastewater project, the treated water volume is 15t / h, the influent water quality: pH: 7.42, total dissolved solids (TDS): 30000mg / L, Cl - : 7860mg / L, SO 4 2- : 7530mg / L, Mg 2+ : 800mg / L, Ca 2+ : 1800mg / L, HCO 3 - : 10.9mg / L, chemical oxygen demand (COD): 450mg / L.

[0084] Treatment requirements: the effluent meets the power plant circulating cooling water standard: pH: 6-9, total dissolved solids (TDS) ≤ 1000mg / L, Cl - : ≤250mg / L, SO 4 2- : ≤250mg / L, total hardness (as CaCO 3 Total) ≤ 450mg / L, chemical oxygen demand (COD) ≤ 50mg / L, effluent reuse, salt separation, and zero discharge treatment of wastewater.

[0085] Selected process:

[0086] Softening pretreatment → ultrafiltration → sodium ion exchanger → nanofiltration salt separation → reverse osmosis → freeze crystallization and evaporation crystallization.

[0087] After the desulfurization wastewater is pre-sedimented in the regulating tank, it enters the first reaction tank 1, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com