High voltage power supply device

A high-voltage power supply and high-voltage technology, applied to electrical devices, motors, electric vehicles, etc., can solve problems that affect driving safety, excessive output torque difference between left and right wheels, and vehicle swaying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

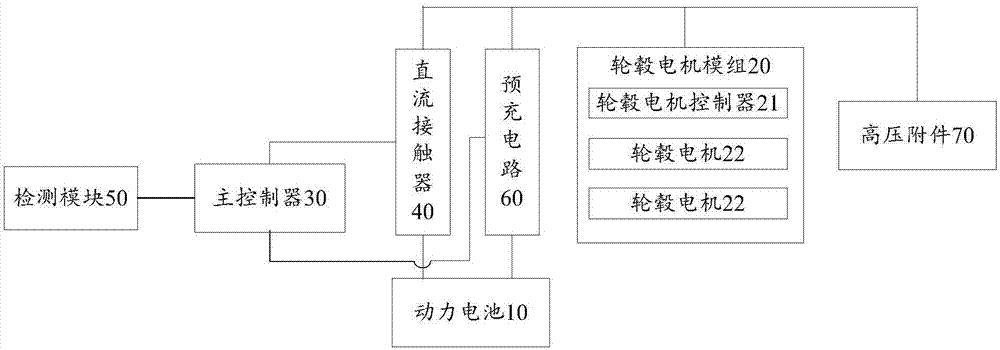

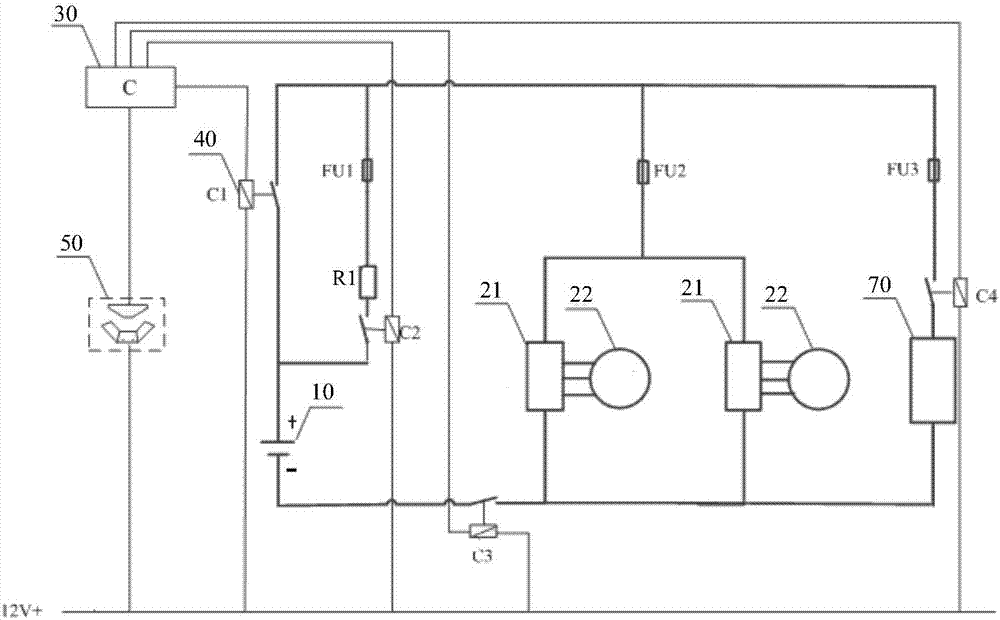

[0036] This embodiment provides a high-voltage power supply device, the high-voltage power supply device is applied to distributed two-drive electric vehicles, see figure 1 as shown, figure 1 A general schematic diagram of a high-voltage power supply device according to an embodiment of the present invention is shown. In this embodiment, the high-voltage power supply device includes a power battery 10 , an in-wheel motor module 20 , a main controller 30 and a DC contactor 40 .

[0037] Specifically, the hub motor module 20 includes a hub motor controller 21 and two coaxial hub motors 22, the hub motor controller 21 is used to control the two hub motors 22; wherein, the two hub motors 22 can be controlled by the hub motor The control of device 21 independently drives left and right front wheels or trailing wheels respectively.

[0038] Wherein, there are two in-wheel motor controllers 21, and the two in-wheel motor controllers 21 respectively control one in-wheel motor 22, and...

Embodiment 2

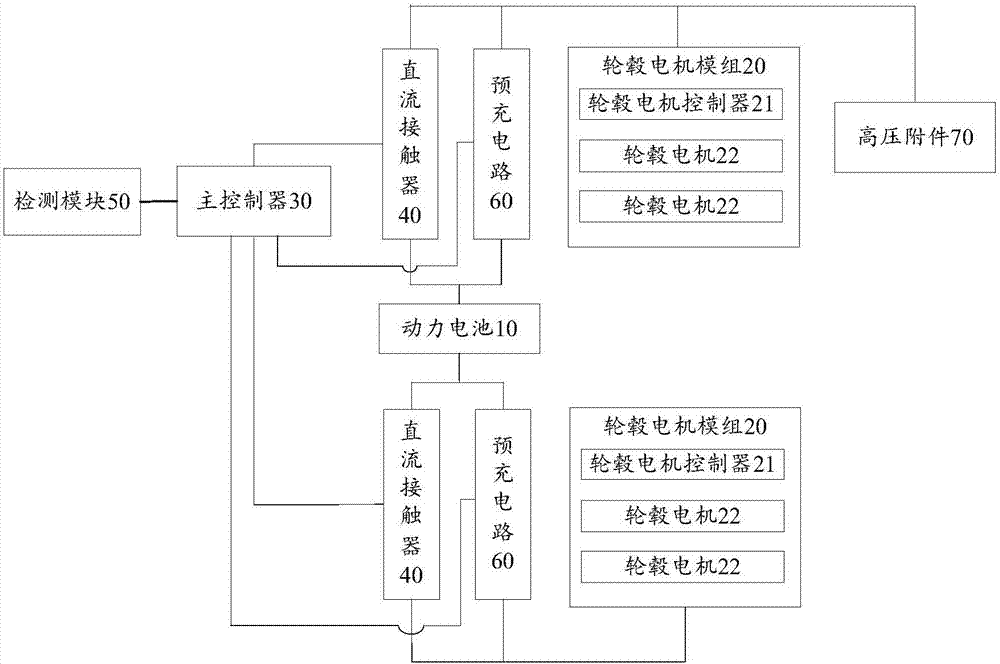

[0054] This embodiment provides a high-voltage power supply device, which is applied to a distributed four-wheel drive electric vehicle and a parallel hybrid electric vehicle driven by a distributed motor. see image 3 as shown, image 3 A general schematic diagram of a high-voltage power supply device according to an embodiment of the present invention is shown. In this embodiment, the high-voltage power supply device is the same as Embodiment 1, the difference is that there are two DC contactors 40 in this embodiment, and there are two in-wheel motor modules 20, and the two DC contactors 40 are respectively connected in series with the high-voltage Between the positive pole of the power battery 10 and the two in-wheel motor modules 20, one of the DC contactors 40 is correspondingly connected to the in-wheel motor controller 21 in one of the in-wheel motor modules 20; the other DC contactor 40 is correspondingly connected to the other The hub motor controller 21 in the hub ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com