Injection molding mold for plastic manifold for engine air intake system of miniature car

An air intake system, injection molding technology, applied in home appliances, other home appliances, applications, etc., can solve the problems of inability to achieve product matching production, poor production efficiency, and occupation of resources, etc., to achieve clever design, improved efficiency, and resources. low-occupancy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

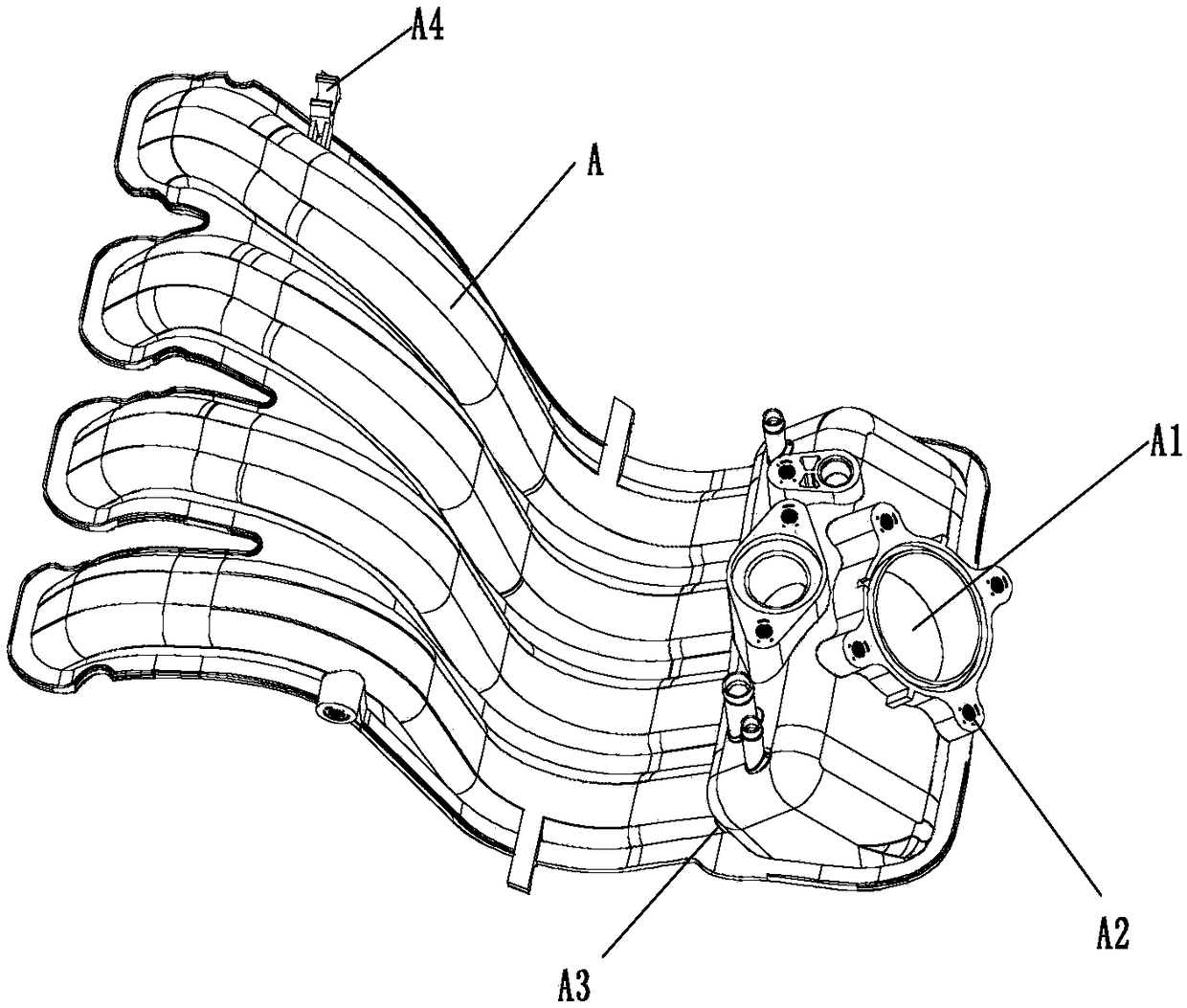

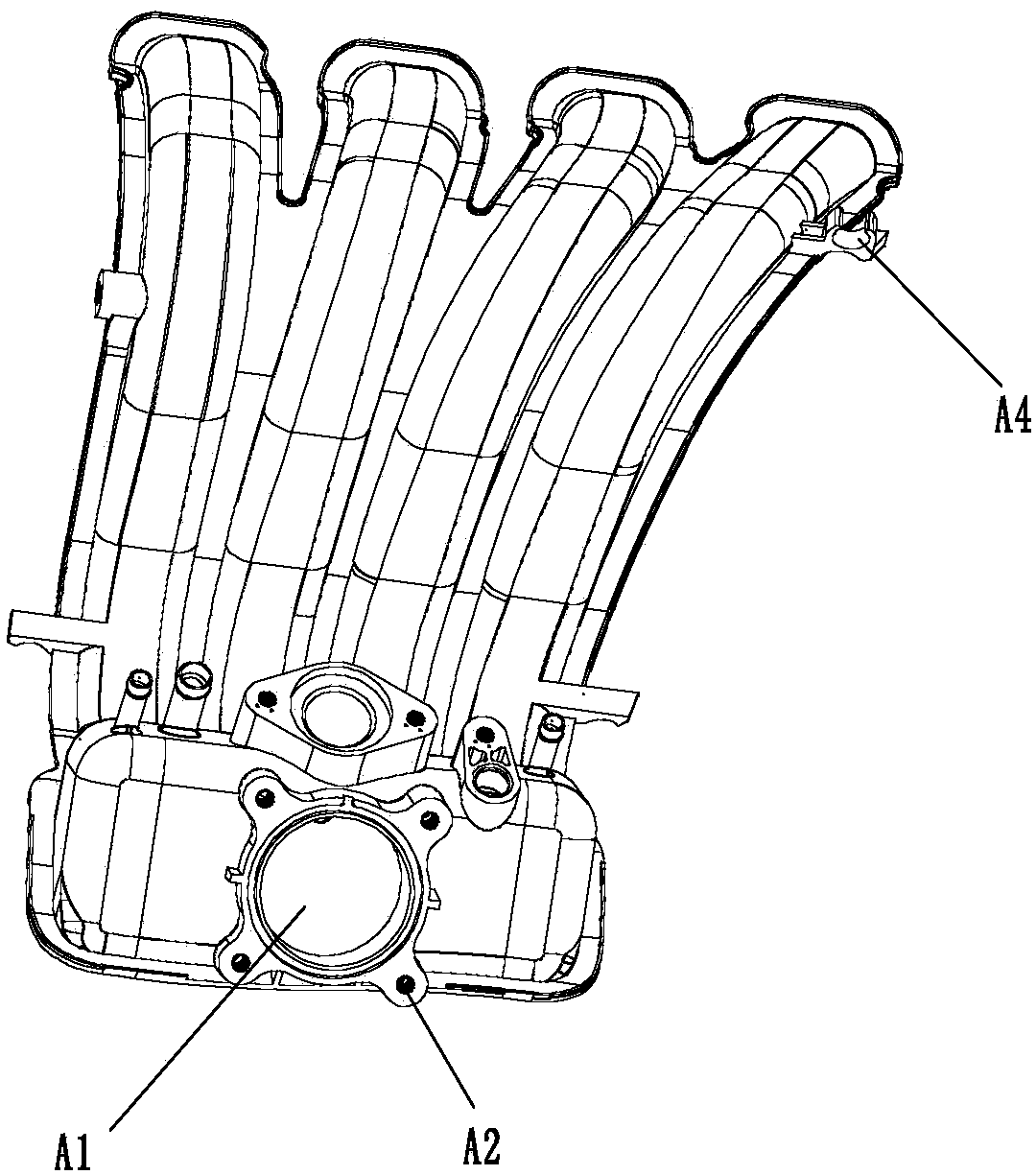

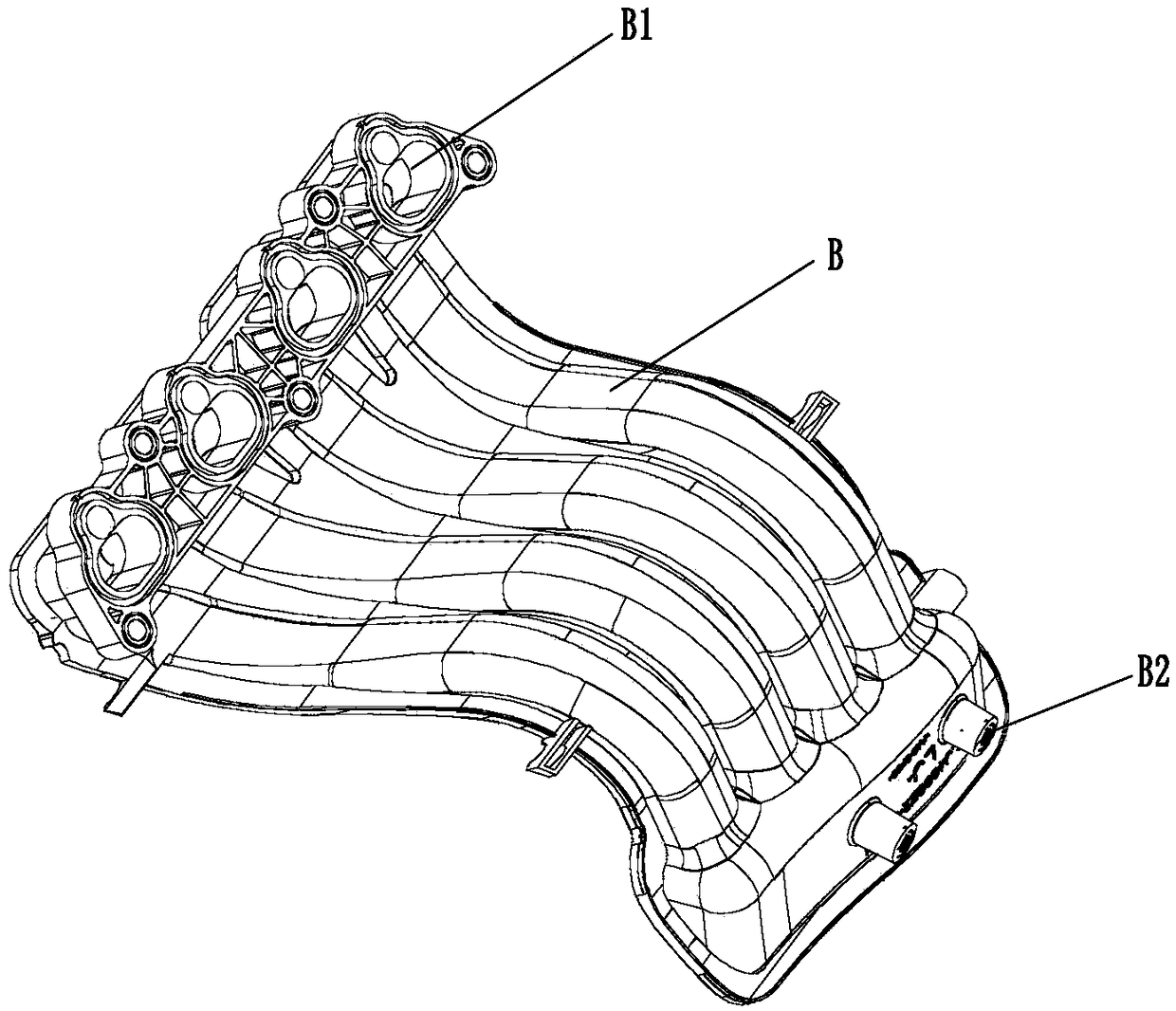

[0033] Embodiment 1: A plastic manifold injection molding mold for the engine air intake system of a miniature car, comprising a front mold 1 and a rear mold 2, the front mold is provided with a guide post 111 and an oblique guide post at the upper intake pipe port of the manifold 13. The oblique guide block of the air outlet port at the lower part of the manifold 15, the nut on the upper part of the manifold is embedded in the oblique guide post 14, the nut on the lower part of the manifold is embedded in the oblique guide post 19, the nut on the front end of the lower part of the manifold is embedded in the oblique guide post 110, the upper pipe of the manifold Clamping guide post 112, the upper core 11 with the same profile as the upper part of the plastic manifold and the lower core 18 with the same profile as the lower part of the plastic manifold, the part of the upper core 11 is set to move forward A movable arc-shaped core assembly 12 that sinks inside the mold, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com