Welding device

A welding device and welding cavity technology, used in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of inability to automatically isolate materials, poor welding accuracy, and high labor intensity of workers, and achieve welding accuracy and high stability. Improve welding accuracy and good dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

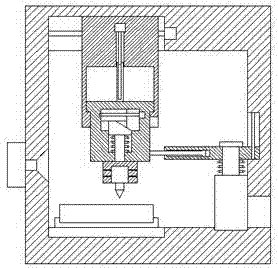

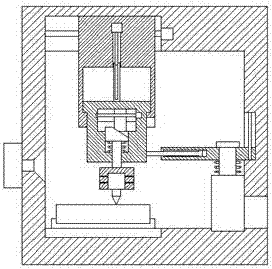

[0024] Such as Figure 1-Figure 5 As shown, a welding device of the present invention includes a casing 5, a welding cavity 51 is provided in the casing 5, and a first sliding groove 53 is provided on the left side of the top of the welding cavity 51. The welding cavity 51 The right side is provided with a second sliding groove 54, and the right side of the housing 5 below the second sliding groove 54 is provided with a port 52 whose left end is connected to the welding cavity 51, and the welding cavity 51 The left and right sides of the inner bottom are respectively provided with a fixed connection device 7 and a sinking groove 55. The first sliding groove 53 is provided with a first screw rod 531 extending left and right, and the first screw rod 531 is threaded. A sliding block 6 whose bottom penetrates into the welding cavity 51 is mated and connected, and a first sliding cavity 61 is provided in the sliding block 6, and a lift-off and landing block is slidingly fitted in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com