Mixed dust collection system used in cutting process of circuit board substrate and using method thereof

A technology of cutting process and dust collection system, applied in the field of circuit board production, can solve the problems of large cost waste, indistinguishability, and high recycling value of aluminum powder, and achieve the effects of cost saving, simple structure and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

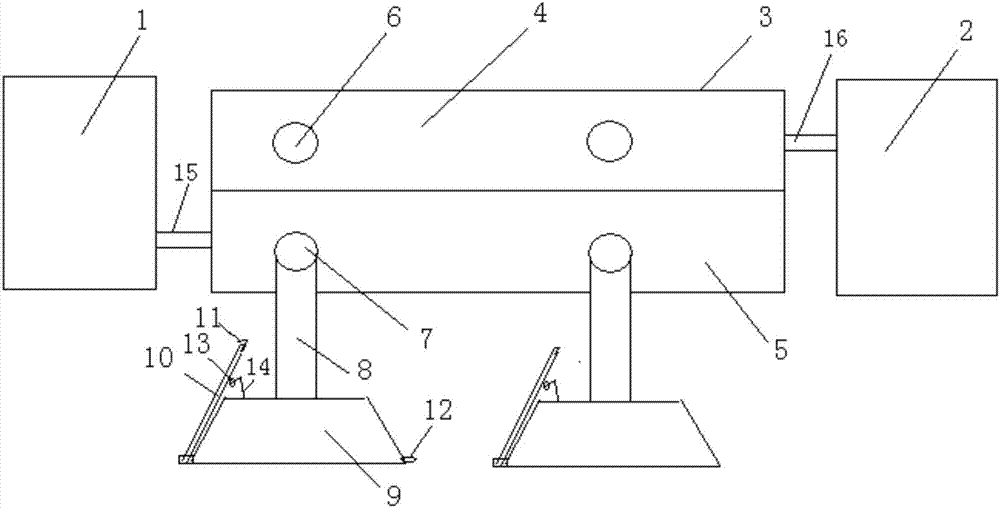

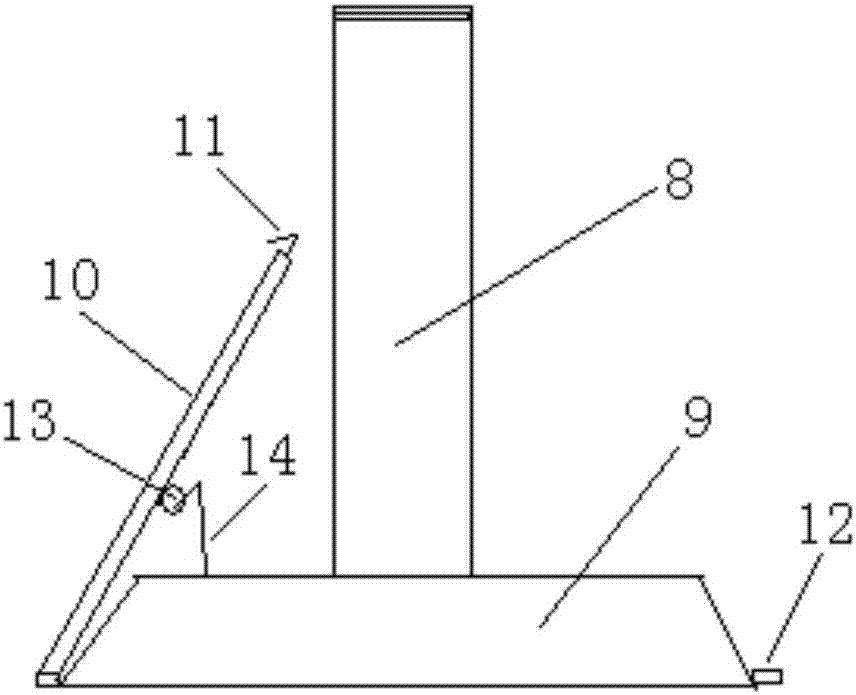

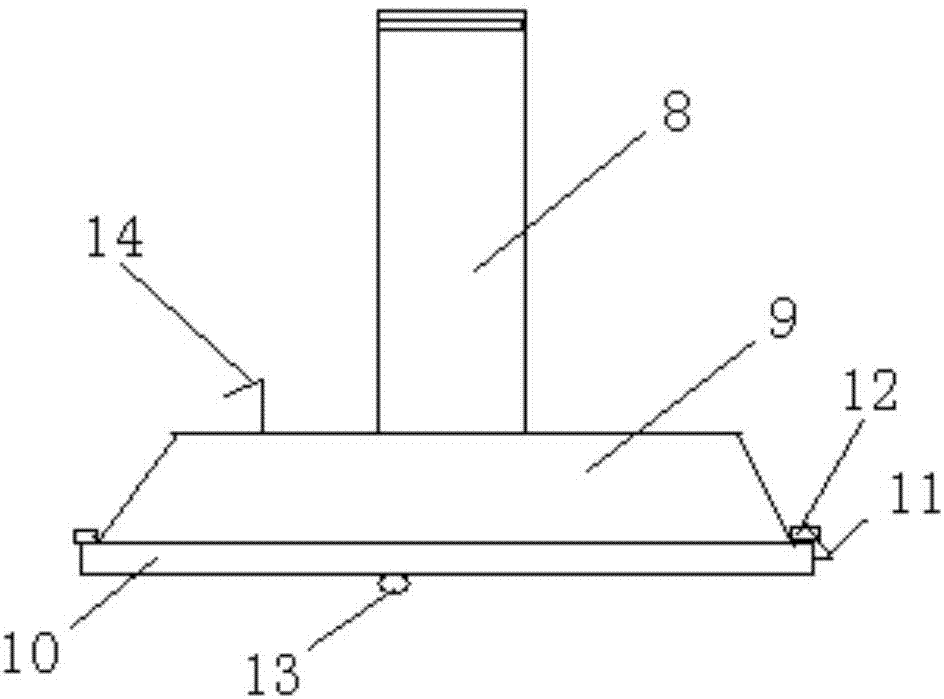

[0027] Such as Figure 1-3 As shown, a mixed dust collection system used in the circuit board substrate cutting process, including an aluminum powder vacuum cleaner, a common powder vacuum cleaner, a first hose, a second hose, a dust chamber, a dust pipe and a dust hood; The dust collection chamber includes a first dust suction channel and a second dust suction channel, the first dust suction channel is connected with the aluminum powder vacuum cleaner through the first hose, and the second dust suction channel is connected with the ordinary powder vacuum cleaner through the second hose Connect; the first dust suction channel is provided with more than two first sockets, and the second dust suction channel is provided with more than two second sockets. The first socket and the second socket are round holes with the same diameter. Both are equipped with internal threads; there are more than two suction pipes and hoods, one end of each suction pipe is connected to the hood, and ...

Embodiment 2

[0037] It is basically the same as Example 1, except that the diameter of the dust suction pipe is 10 cm; the diameter of the bottom surface of the dust suction hood is 30 cm. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com