Spiral bottle box integral ultrasonic cleaning machine and method thereof

A technology of ultrasonic wave and cleaning machine, which is applied in the direction of cleaning methods using liquids, cleaning methods and utensils, chemical instruments and methods, etc., which can solve the problems of large impact on production line efficiency, high equipment manufacturing costs, unstable operation, etc., and achieve effective Helps thorough cleaning and reduces the power required for transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the technical means, creative features, goals and effects of the present invention realized easily

[0038] For clear understanding, the present invention will be further described below in conjunction with specific embodiments.

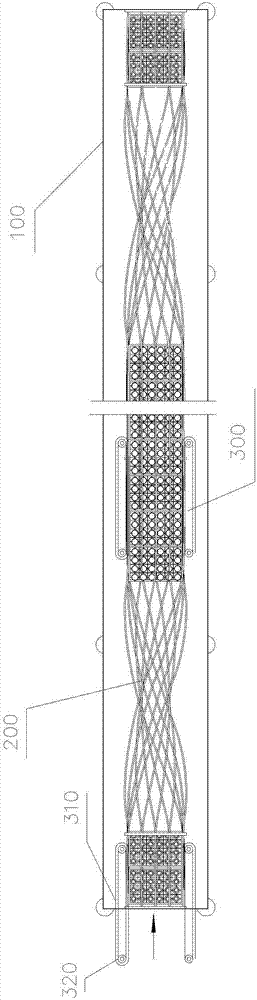

[0039] see figure 1 to map Figure 7, the embodiment of the present invention provides four kinds of spiral bottle case integrated ultrasonic cleaning machine, which includes a case body 100 provided with a cleaning liquid and an ultrasonic generator 400 arranged in the case body 100, which is useful for installation in the case body 100 The sliding spiral cleaning channel 200 for transporting the box to be cleaned and the driving device 300 for driving the box to be cleaned are placed in the cleaning liquid of the box body 100, and its two ends are located on both sides of the box body 100. The sliding screw The heights of both ends of the cleaning channel 200 are higher than the middle height of the sliding spiral cleaning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com