A kind of atrioventricular valve support and its delivery system for puncture implantation

A technique for an atrioventricular valve and a delivery system, which is applied to the field of an atrioventricular valve stent for puncture implantation and its delivery system, and achieves the effects of high success rate, prevention of paravalvular leakage, and convenient and safe implantation operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] Example 1: Puncture and placement through the left ventricular apical approach

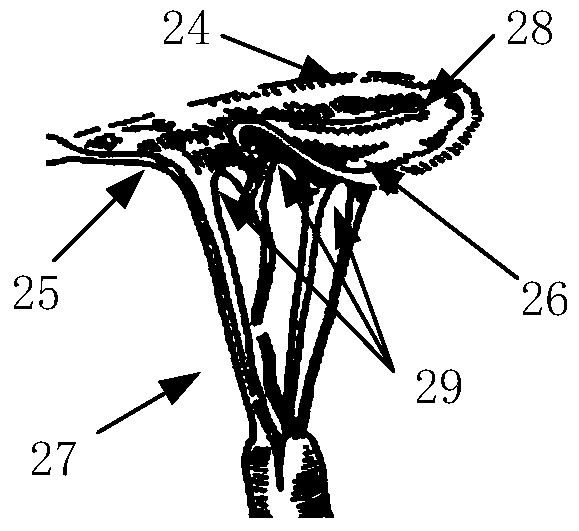

[0075] The surgical approach for valve stent placement via the left ventricular apical approach is as follows: Figure 6 As shown in the figure, the valve support 10 is partially released, and the fixing arm is opened to hook the anterior leaflet 25 and the posterior leaflet 26 of the mitral valve;

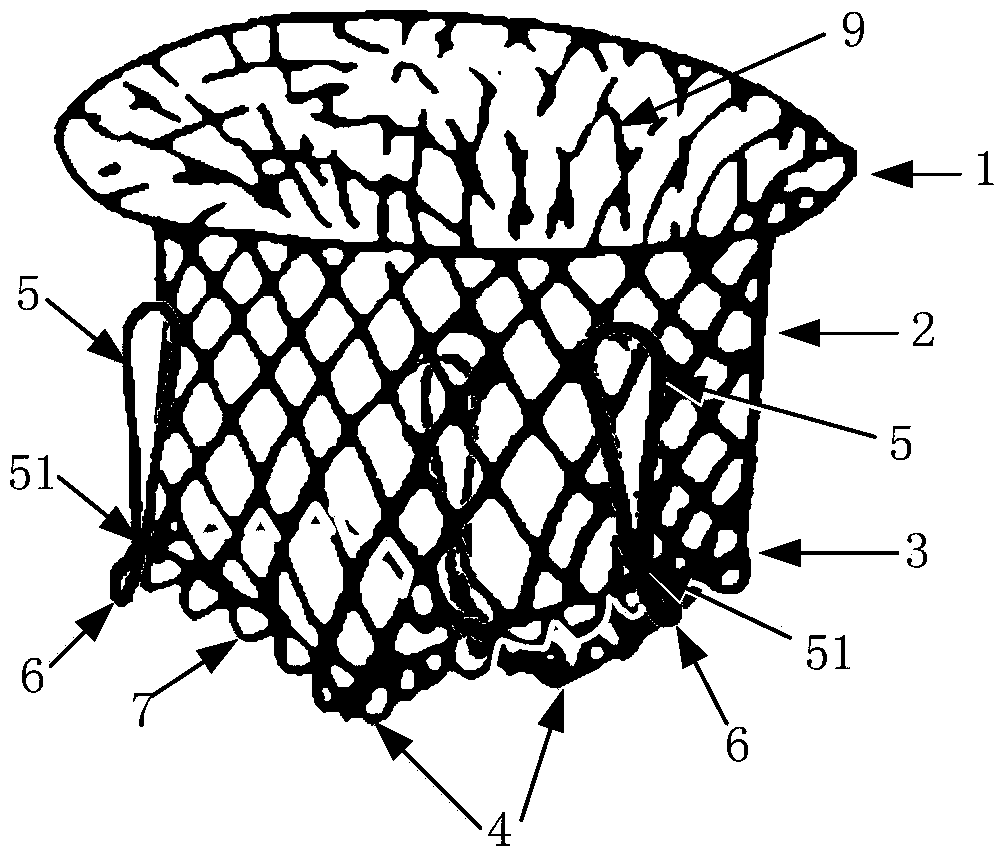

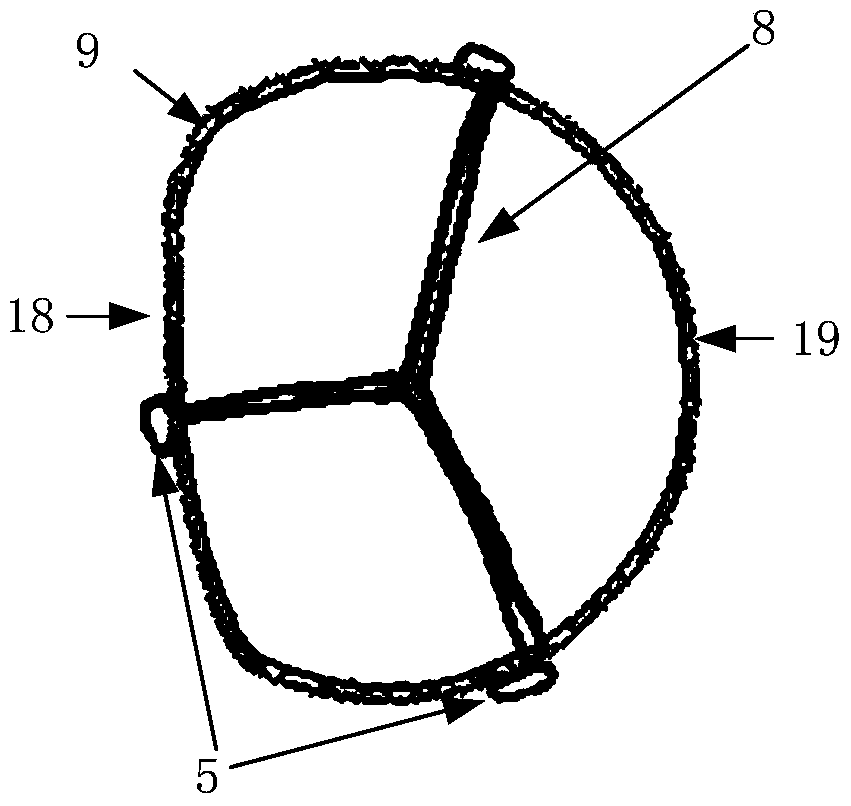

[0076] Before the operation, the valve stent 10 is first compressed into the delivery system, wherein the front end of the valve stent 10 is the left atrial side fixed part 1 of the expandable outer stent 9, and is compressed in the head end sheath tube 13 at the head end of the inner core 17, and the valve stent The rear end of 10 includes the left ventricle side fixing part 3 of the expandable outer stent 9, the barb part 6 of the fixing arm 5 and the anti-reflux edge 4 between valves, which are compressed in the outer sheath tube 14 of the delivery system, and the pulling wire 15 Put it o...

Embodiment 2

[0082] Example 2: Through the left ventricular apex approach, the fixed part 1 on the left atrial side releases the expansion first

[0083] The embodiment of valve stent implantation through the left ventricular apex approach, and the expansion of the fixed part 1 on the left atrial side is released first Figure 11 As shown in the figure, the valve support 10 is partially released, the fixing arm is opened to hook the anterior leaflet 25 and the posterior leaflet 26 of the mitral valve, and the left atrial side fixing part 1 is opened. In this embodiment, the first and second steps of the valve support release process are exactly the same as in Embodiment 1, but the fixed arm 5 released after the valve support 10 is opened to hook the anterior leaflet 25 and the rear leaflet of the mitral valve. After the valve leaflet 26, the front part of the valve support 10 is released from the head end sheath tube 13 by pushing the inner core 17, so that the left atrium side fixing pa...

Embodiment 3

[0084] Example 3: Puncture placement through the left atrium

[0085] Figure 12 It is an embodiment of the surgical approach for valve stent implantation through the left atrium approach, and the insertion direction of the valve stent 10 in the delivery system is as follows: Figure 12 As shown in the figure, the valve support 10 is partially released, and the fixed arm is opened to hook the anterior valve leaflet 25 and the posterior valve leaflet 26 of the mitral valve; the left atrial side of the valve support 10 is placed at the proximal end of the delivery system, and the external The left atrial side fixing part 1 of the stent 9 is compressed in the outer sheath tube 14 as the rear end of the valve stent 10; and the intervalvular anti-reflux edge 4, as the front end of the valve stent 10 is compressed into the head end sheath tube 13 of the inner core head end 12; the pulling wire 15 is set on the edge of the bracket of the left atrial side fixing part 1, and the pul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com