Air-drying method for corn seed production and corn seed production method

A technology of corn and air-drying nets, which is applied in the agricultural field, can solve the problems of many germinated moldy seeds and general seed quality, and achieve the effect of low defective rate and high germination rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

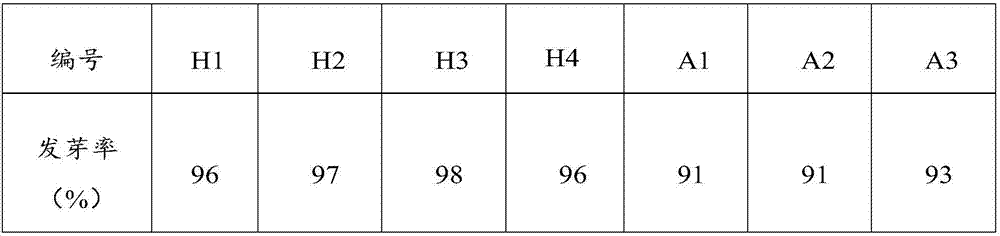

Examples

Embodiment 1

[0026] Harvest mature corn ears on September 30th of the first year, peel them and spread them in the sun after cleaning up impurities greater than 5cm, fill up ditches with a depth or width greater than 5cm, set up fences around them, disinfect with 10kg of quicklime per mu and lay a long layer. 50m wide and 6-10m black drying nets are used for drying. The average daily sunlight is 9 hours, the daily average temperature is 10°C, the relative humidity is 3%, the groundwater level is 10m, and the surface moisture content is 3%. At the same time, the slope of the drying site is less than 50 degrees and the surrounding area is open and well ventilated. The corn ears are piled up in 2 layers for drying.

[0027] During the drying process of corn ears, an isolation area with a width of 5m is set up between the adjacent drying areas of different varieties of corn. Turn over once every 3 days, and after 15 days of drying, the moisture content of corn kernels in all corn ears is less...

Embodiment 2

[0030] On September 15th of the second year, the mature corn ears were harvested and peeled, and spread out in the sun after cleaning up the impurities larger than 5cm, filling the ditches with a depth or width larger than 5cm, setting up fences around them, disinfecting with 10kg quicklime per mu, and laying a long layer. 50m wide and 6-10m black drying net drying site, the average daily sunlight of the drying site is more than 9 hours, the daily average temperature is 10.5°C, the relative humidity is 2.7%, the groundwater level is 11m, and the surface moisture content is 2.8%. At the same time, the slope of the drying site is less than 50 degrees and the surrounding area is open and well ventilated. The ears of corn are stacked in 4 layers for drying.

[0031]During the drying process of corn ears, a 6m-wide isolation zone is set up between the adjacent drying areas of different varieties of corn. Tumbling once every 5 days, after 17 days of drying, the moisture content of ...

Embodiment 3

[0034] On September 20th of the third year, mature corn ears are harvested and peeled, and placed in a place where impurities greater than 5cm are cleaned, ditches with a depth or width greater than 5cm are filled, fences are set around, 10kg of quicklime is used for disinfection per mu, and a layer of 50m long is laid. A drying site for black drying nets with a width of 6-10m. The average daily sunlight of the drying site is more than 9 hours, the average daily temperature is 11°C, the relative humidity is 2.5%, the groundwater level is 12m, and the surface moisture content is 1.9%. At the same time, the slope of the drying site is less than 50 degrees and the surrounding area is open and well ventilated. The corn ears are piled up in 6 layers for drying.

[0035] During the drying process of corn ears, a 5m-wide isolation zone and a 1m working path shall be set up between adjacent drying areas of different varieties of corn. Turn over once every 8 days, and after 20 days of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com