X-ray tube and preparation method therefor

A technology of X-ray tube and ceramic shell, which is applied in the field of X-ray tube, can solve the problems of glass tube damage, poor pressure resistance performance of cold and heat alternating performance, affecting the yield and service life of the tube, etc., to ensure stable work, The effect of improving the vacuum degree in the tube

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to describe the technical features and functions of the present invention in detail, and to implement them according to the content of this specification, the following further describes the implementation modes of the present invention.

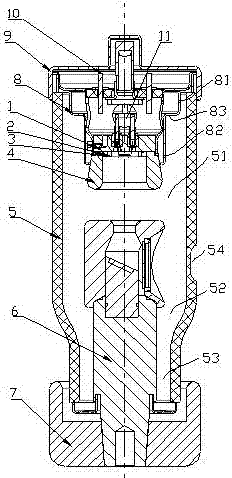

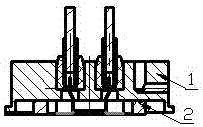

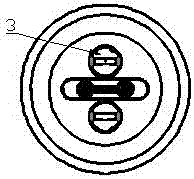

[0042] figure 1 An exemplary embodiment of an X-ray tube among numerous embodiments of the invention is shown. The X-ray tube includes a focusing electrode 1 , a focusing electrode positioning piece 2 , a focusing cover 4 , a ceramic shell 5 , an anode 6 , a shielding cover 8 and a cathode 11 .

[0043] The ceramic housing 5 includes a cavity including a first portion 51 , a connecting portion 52 and a second portion 53 . The first part 51 is cylindrical. One end of the connecting portion 52 is connected to one end of the first portion 51 . The second part 53 is cylindrical, and one end of the second part 53 is connected to the other end of the connecting part 52 . The diameter of the first part 51 is greater than that of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com