Tube coiling machine for quick-dry firework paper tube

A reel machine and paper reel technology, which is applied in pyrotechnics, cardboard winding products, offensive equipment, etc., can solve the problem that the paper softening effect is difficult to adapt to the requirements of the reel, the outer ring seal of the paper reel is degummed and cracked, stability and practicability No high-level problems, to achieve the effect of eliminating paper breakage, improving the quality of finished products, and reliable and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

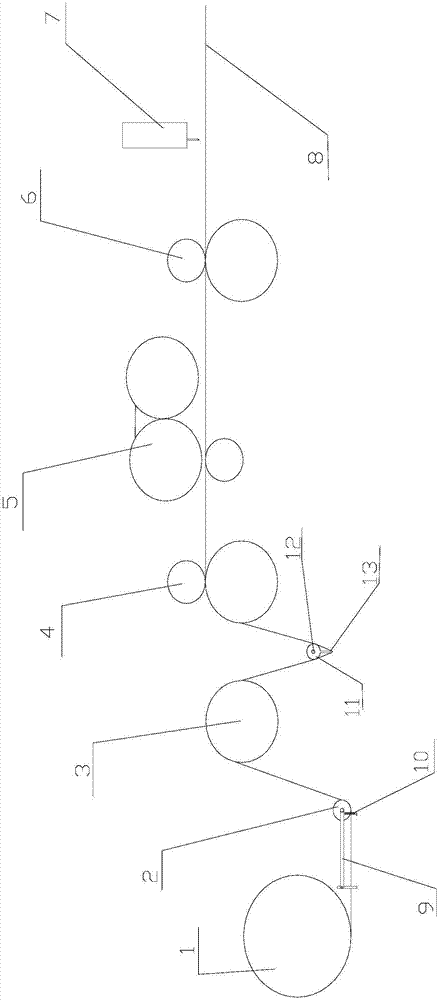

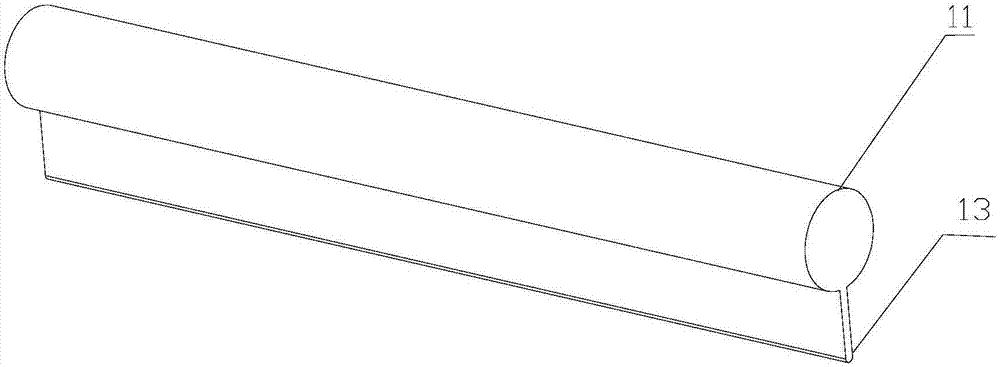

[0037] Example 1: See attached Figure 1-5 Reflecting a specific structure of the present invention, the quick-drying firework paper roll reel includes a base paper roll 1 and a supporting roller 3, a first paper feeding roller set 4, and a gluing mechanism arranged in sequence along the paper feeding direction. 5. The second paper feeding roller group 6. The paper cutting mechanism 7. The paper feeding roller group pulls the paper 8, and the supporting roller 3, the first paper feeding roller group 4 and the second paper feeding roller group 6 send the paper 8 of the base paper roll 1 to the paper cutting mechanism 7. The gluing mechanism 5 includes two glue rollers on the paper. The two glue rollers are arranged side by side, the roller surfaces are close together, and a glue tank for holding glue is formed between the two roller surfaces. The glue roller is connected to the driving mechanism to rotate actively, corresponding to the glue roller The roller is set under the pap...

Embodiment 2

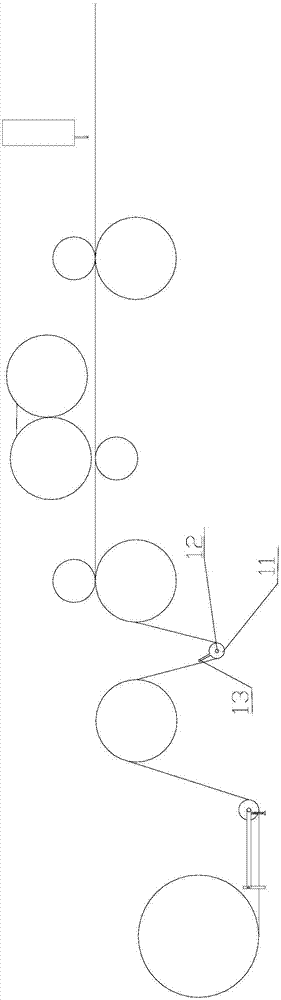

[0046] Example 2: See attached Figure 6-9 Reflecting a specific structure of the present invention, the quick-drying firework paper roll reeling machine includes a base paper roll 106, a supporting roller 107, and a paper feeding roller group 109 arranged in sequence along the paper feeding direction. The gluing mechanism, the paper cutting mechanism, the reel mechanism, the cutting mechanism, and the unwinding mechanism are all the same, not shown. The difference from Example 1 is:

[0047] 1. The specific structure of the softening element is different, and it also includes a smooth end 101 and a soft end 102. The softening element rotates on its body under the action of the driving mechanism, and realizes the switch between state A and B through rotation, state A: soft The smooth end 101 of the softening element is in contact with the paper 108 at the bottom corner of the V-shaped fold; state B: the soft end 102 of the softening element is in contact with the paper 108 at th...

Embodiment 3

[0050] Example 3: See attached Picture 10 , 11 , Which reflects a specific structure of the present invention. The difference from Embodiment 2 is:

[0051] 1. The paper relaxing member 203 is provided with an elastic member. The elastic member is a compression spring 205 set on the positioning rod 204 to press the paper relaxing member 203. The paper relaxing member 203 faces the paper based on its own weight and the action of the elastic member. Press the paper below.

[0052] 2. The setting of the rotation angle of the softening element is different, but the following conditions are still met: State A: the smooth end 201 of the softening element is in contact with the paper at the corner of the bottom of the V-shaped fold; State B: the softening element The soft end 202 of the V-shaped fold is in contact with the paper at the bottom corner. The purpose of the invention can also be achieved.

[0053] The rest are the same as in Embodiment 2, and will not be repeated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com