Multiple-degree-of-freedom controlled variable design-based output tracking robustness forecast control method

A technology of predictive control and control quantity, which is applied in the field of output tracking robust predictive control based on multi-degree-of-freedom control quantity design, and can solve problems such as not taking into account external disturbances of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

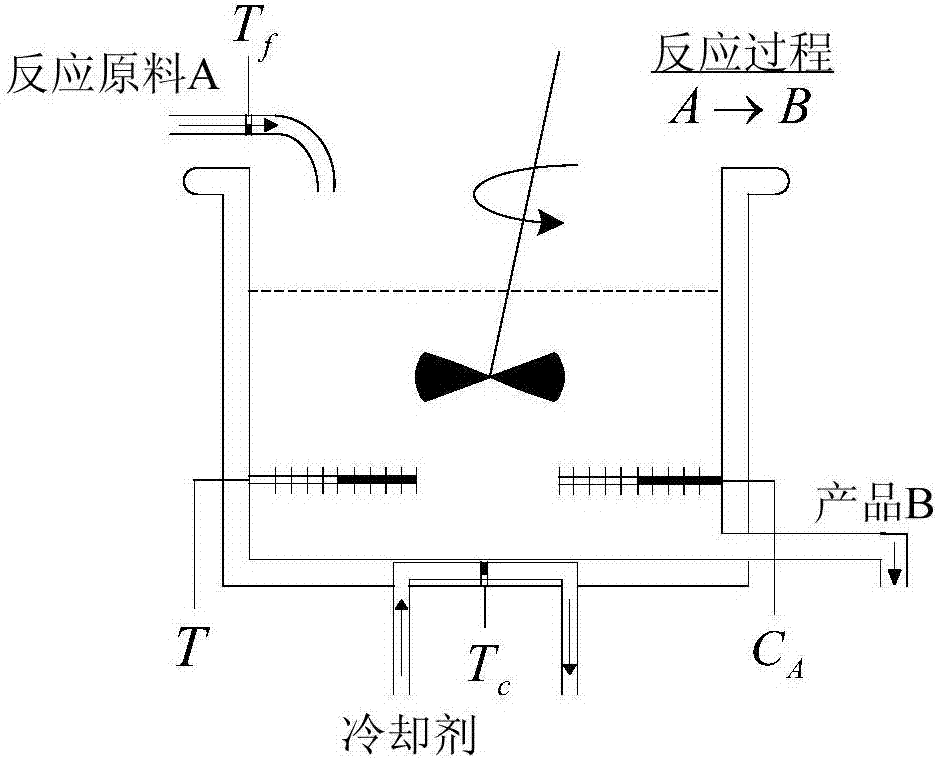

[0060] The concrete implementation schematic diagram that the present invention is applied to CSTR (continuously stirred reactor) system is as figure 1 shown. In this specific implementation, an exothermic and irreversible reaction occurs in the CSTR system. The reaction raw material is A and the product is B. The reaction raw material A flows into the reactor at a certain flow rate, and the generated reaction material flows out of the reactor at the same flow rate. The relevant parameters in the CSTR system as shown in Figure 1 are: the reaction temperature in the reactor is T, and the coolant temperature is T c , the feed concentration of reaction raw material A is C Af =1mol / L, feed flow is Q f =100L / min, feed temperature is T f =350K, the reactor volume is V=100L, and the specific heat is C p =0.25J / g·K, the concentration of A after the reaction is C A , the product of the heat transfer coefficient and the reactor surface area is UA h =5.8×10 4 J / (mingk). In this e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com