Cast part oil-immersion device

A technology of oil immersion and casting, applied in engine components, lubricating parts, engine lubrication, etc., can solve the problems of low work efficiency and high labor intensity of staff, achieve high work efficiency, improve infiltration effect and product quality , the effect of reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

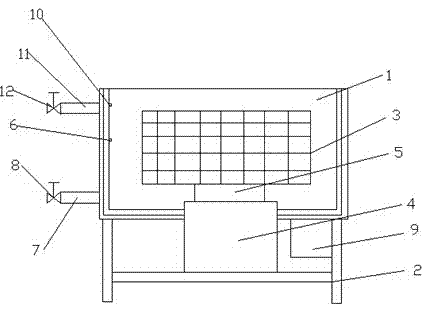

[0016] Such as figure 1 As shown, a casting oil immersion device of the present invention includes an oil immersion tank 1, the bottom of the oil immersion tank 1 is provided with a support frame 2, and the inside of the oil immersion tank 1 is provided with a workpiece frame 3 for placing castings, and the support frame 2 is provided with a cylinder 4, the cylinder arm 5 of the cylinder 4 is in contact with the bottom of the workpiece frame 3, the inside of the oil immersion tank 1 is provided with lubricating grease, and the inner wall of the oil immersion tank 1 is provided with a piezoelectric sensor 6, so The outer side of the oil immersion tank 1 is provided with a steam inlet pipe 7 communicating with it, and the steam inlet pipe 7 is provided with a solenoid valve 8 , and both the piezoelectric sensor 6 and the solenoid valve 8 are connected to a control unit 9 .

[0017] Preferably, as a possible embodiment, a liquid level sensor 10 is installed on the upper side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com