Outer one-way adjustable telescopic corrugated pipe

A bellows, adjustable technology, applied in the direction of pipe elements, pipes/pipe joints/pipes, expansion compensation devices for pipelines, etc. Achieve the effect of reducing compression deformation, ensuring safety, and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

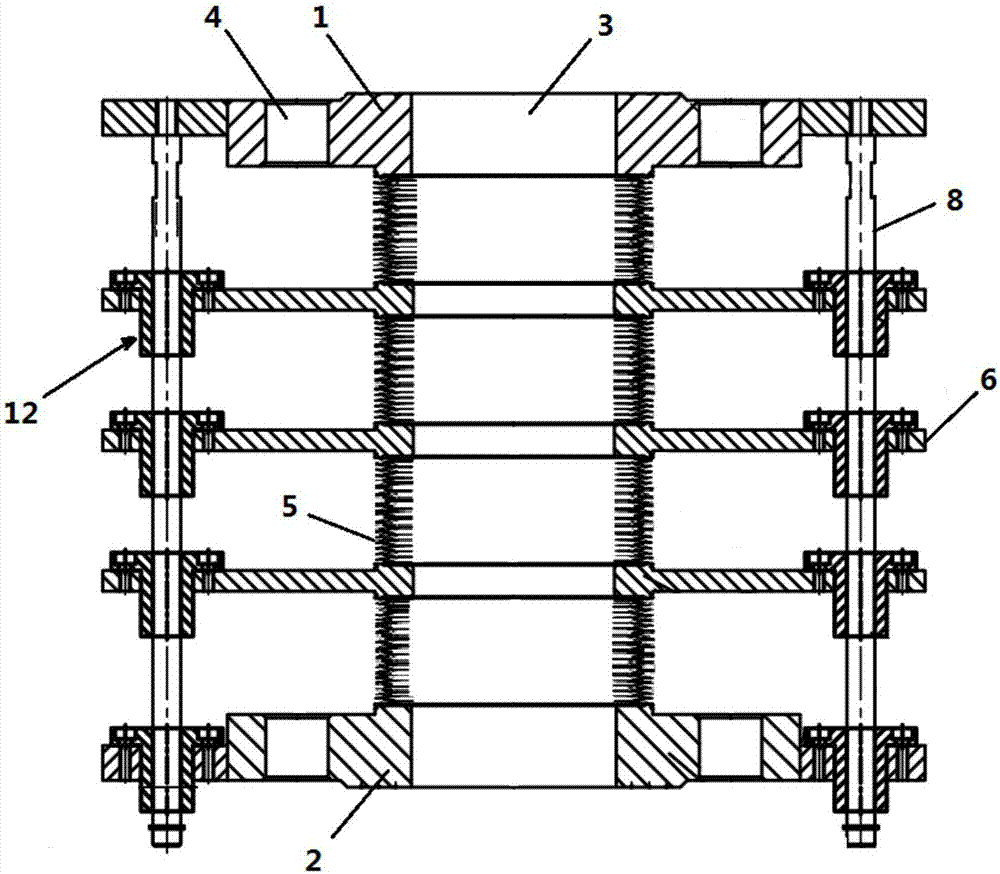

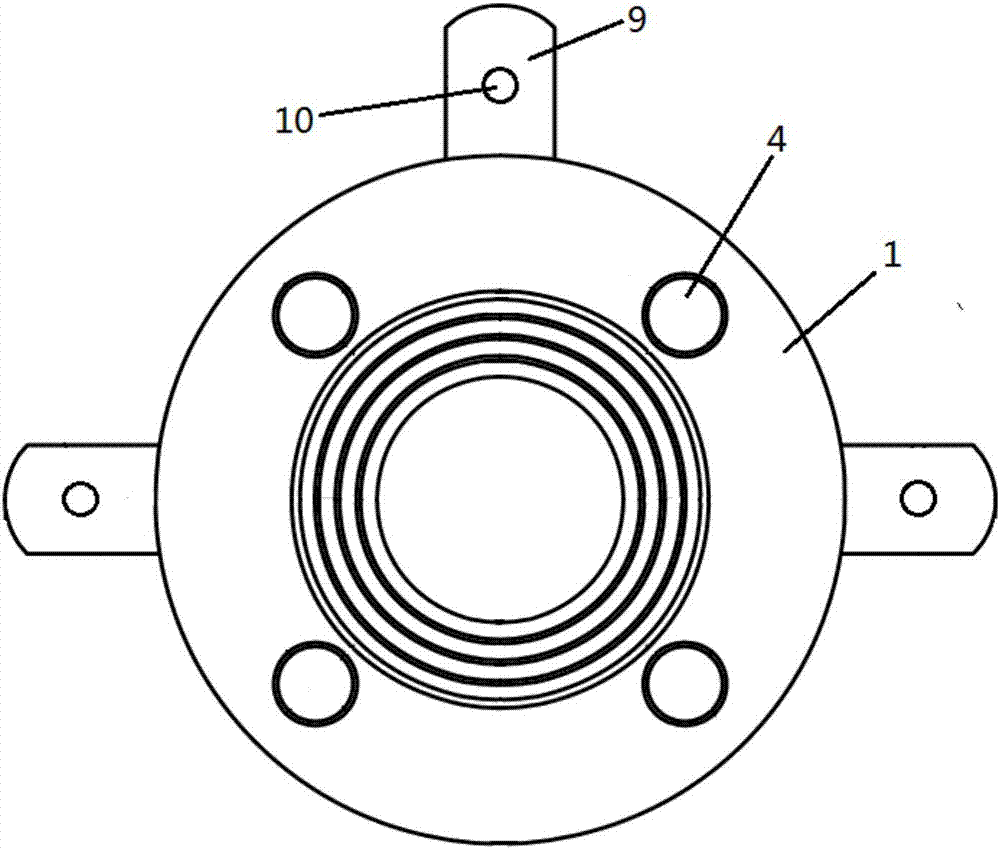

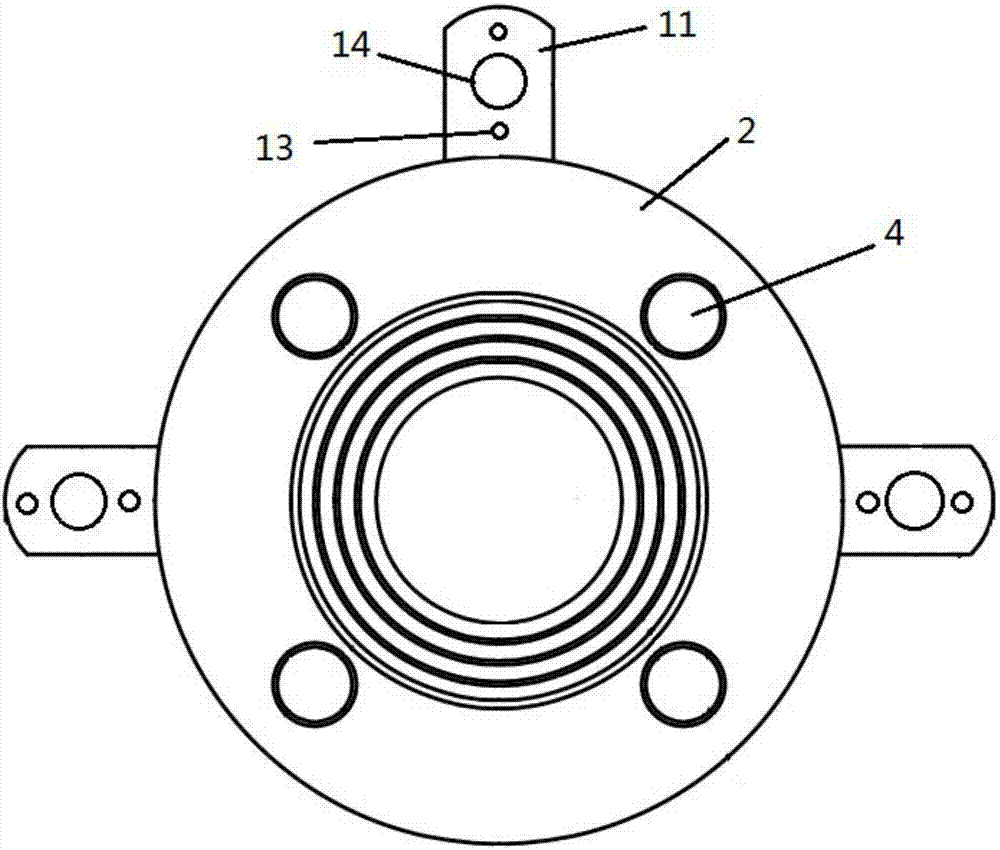

[0022] combine figure 1 , figure 2 with image 3 As shown, the outer one-way adjustable telescopic bellows includes a first fixing part 1 and a second fixing part 2, and the first fixing part 1 and the second fixing part 2 are both flanges, and the flanges There is a pipe hole 3 in the middle part, and there are installation holes 4 around the pipe hole 3, through which the flange plate can be locked on the pipeline that needs maintenance; the first fixing member 1 and the second A telescopic bellows device is provided between the fixing parts 2, and the two ends of the telescopic bellows device are welded to the first fixing part 1 and the second fixing part 2, and the edge of the first fixing part 1 is provided with a first fixing ear 9. The first fixing ear 9 is provided with a screw hole 10, and the screw hole 10 is provided with an internal thread, and the edge of the second fixing member 2 is provided with a second fixing ear 11, and the second fixing ear 11 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com