Drain trap with backward flowing prevention function and difficult drying effect of water seal

A water trap and anti-backflow technology, applied in water supply installations, indoor sanitary pipe installations, buildings, etc., can solve the problems of loss of water seal, reduction of float floating stroke, backwater backflow, etc., to achieve effective sealing and maintain water sealing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

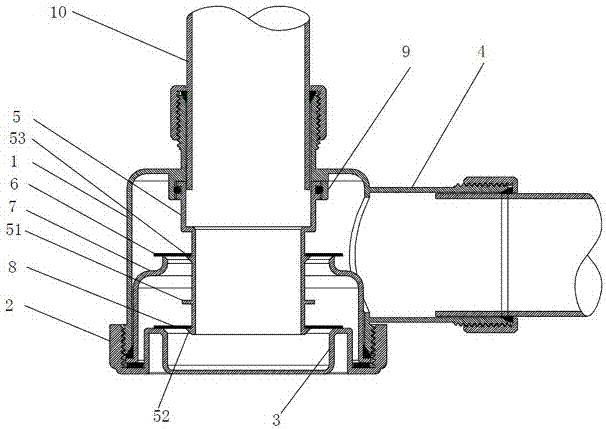

[0035] figure 1 The shown water trap is an embodiment of the present invention, including a water trap housing and a water sealing structure disposed in the housing, and the water trap housing includes a casing 1 and a bottom cover 2 . The shell 1 is cylindrical, with a drain pipe interface 4 on one side, external threads on the outer edge of the lower end, and a pipe joint connected to the sink drainer at the center of the top. The upper outer wall of the pipe joint has threads for the sink. Connector screw connection. The bottom cover 2 is provided with an internal thread adapted to the external thread of the shell 1 for connecting with the shell 1 to form a complete shell of the water trap. The bottom cover 2 has a vertically protruding protruding ring as the supporting protruding ring 3 , which is formed by the material of a local area of the bottom cover 2 arching upward.

[0036] The water seal structure includes a water seal outer cover 7 , a water seal inner cover...

Embodiment 2

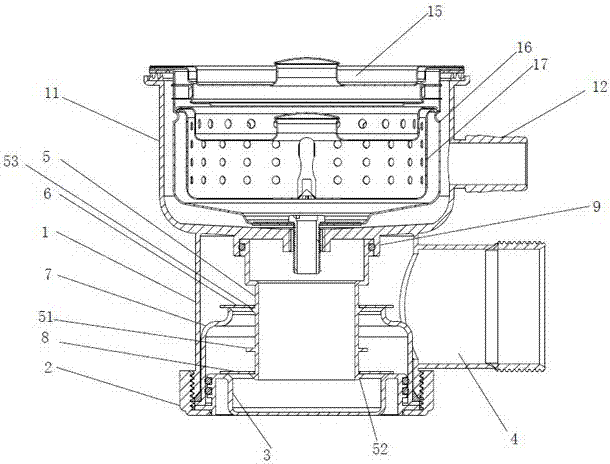

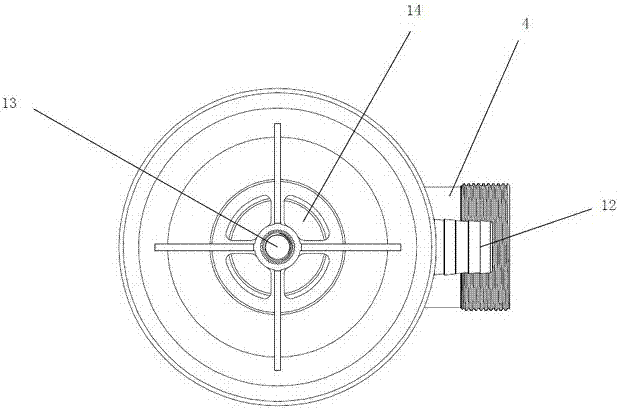

[0040] The difference from Embodiment 1 is: as figure 2 As shown, the sink drain is cup-shaped, which includes a cup-shaped drain main body 16 , a filter basket 17 and a surface cover 15 . Correspondingly, the top of the housing 1 in this embodiment is provided with a cylindrical body 11 whose inner diameter is larger than the outer diameter of the sink drainer, as a sleeve for fitting the drainer. A water overflow nozzle 12 is arranged on the sleeve, and when the water has no time to flow out through the water trap, the water is allowed to directly flow into the drainpipe from the water overflow nozzle 12 . Such as image 3 As shown, in this embodiment, a screw hole 13 is provided in the middle of the top surface of the water trap housing 1, and water leakage holes 14 are arranged around it. When installing, the drain main body 16 and the water trap housing 1 are connected at the screw holes 13 of the water trap housing 1 by screws and nuts, so that the water trap and the ...

Embodiment 3

[0042] The difference from Embodiment 1 is: as image 3 As shown, the water-sealed outer sleeve 7 is a vertical straight cylinder with an inner diameter larger than the water-sealed inner sleeve 5, and its bottom is sealed with the bottom cover 2, and the lower pipe section of the water-sealed inner sleeve 5 extends into the inner cavity of the water-sealed outer sleeve 7. At the position corresponding to the lower port of the vertical annular water channel, the inner wall of the water-seal outer cover 7 is provided with a radially protruding protruding ring along the inner perimeter, as a supporting protruding ring 71, which is connected with the water-sealing inner sleeve 5. The lower inner flange 52 is flush. In this embodiment, the outer diameter of the lower floating cover 8 is smaller than the inner diameter of the water-sealed overcoat 7, so that there is a distance between the outer contour edge of the lower floating cover 8 and the inner wall of the water-sealed overc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com