Environment-friendly high-precision autoclaved aerated block cutting machine

An autoclaved aeration, high-precision technology, which is applied in the field of environmental protection and high-precision autoclaved aerated block cutting machines, can solve the problems of low precision, movement of the autoclaved aerated block, and low degree of automation, and achieves simple structure and cutting. Precise positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

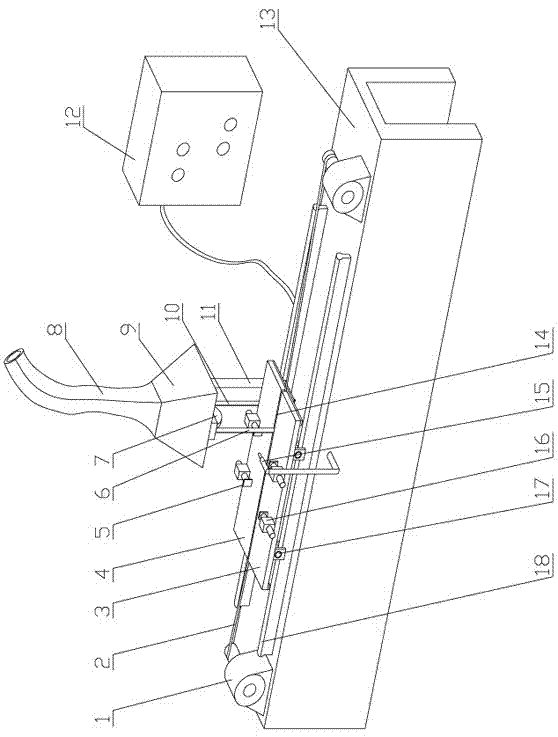

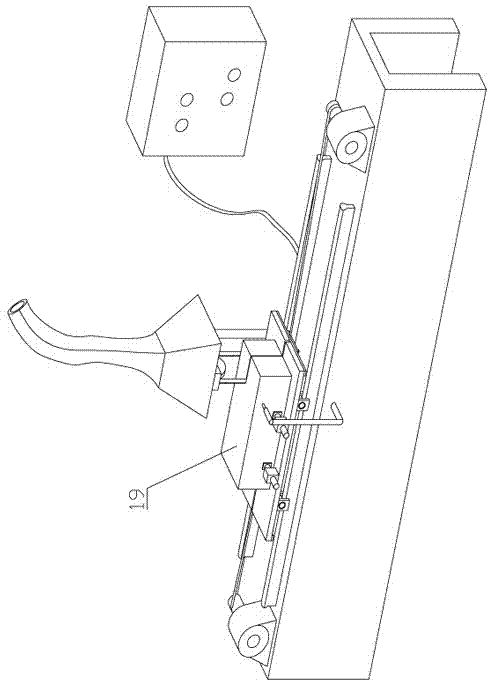

[0014] see figure 1 , the present invention is an environmental protection high-precision autoclaved aerated block cutting machine, which has a workbench 13, a support frame 11 is provided in the outer middle part of the workbench, and a transmission wheel 7 is respectively provided on the upper part and the lower part of the support frame, and the transmission wheel passes through The driving motor is driven to rotate, and the transmission wheel is set with a circular band saw blade. The circular band saw blade includes an inner segment saw blade 6 and an outer segment saw blade 10. On the outside of the table, two rails 18 are arranged symmetrically on both sides of the inner saw blade on the top of the workbench. The direction of the rails is parallel to the circular band saw blade. , the bottom of the table is provided with a roller 17, the roller rolls along the track, a section of cutting seam 14 is provided in the middle of the table along the cutting direction of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com