Double-flow type liquid way variable transmission system

A transmission system, double-flow technology, applied in the direction of liquid injection device, injection device, etc., can solve the problem that the transmission system does not have a variable adjustment device, etc., to reduce the loss of liquid medicine, simple structure, improve the effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

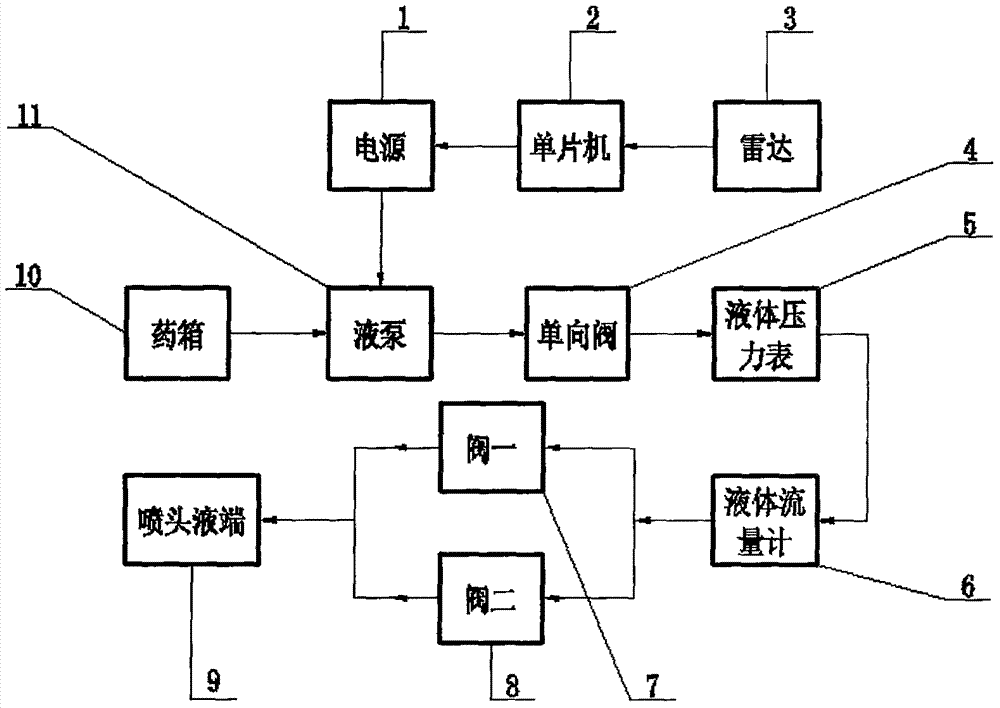

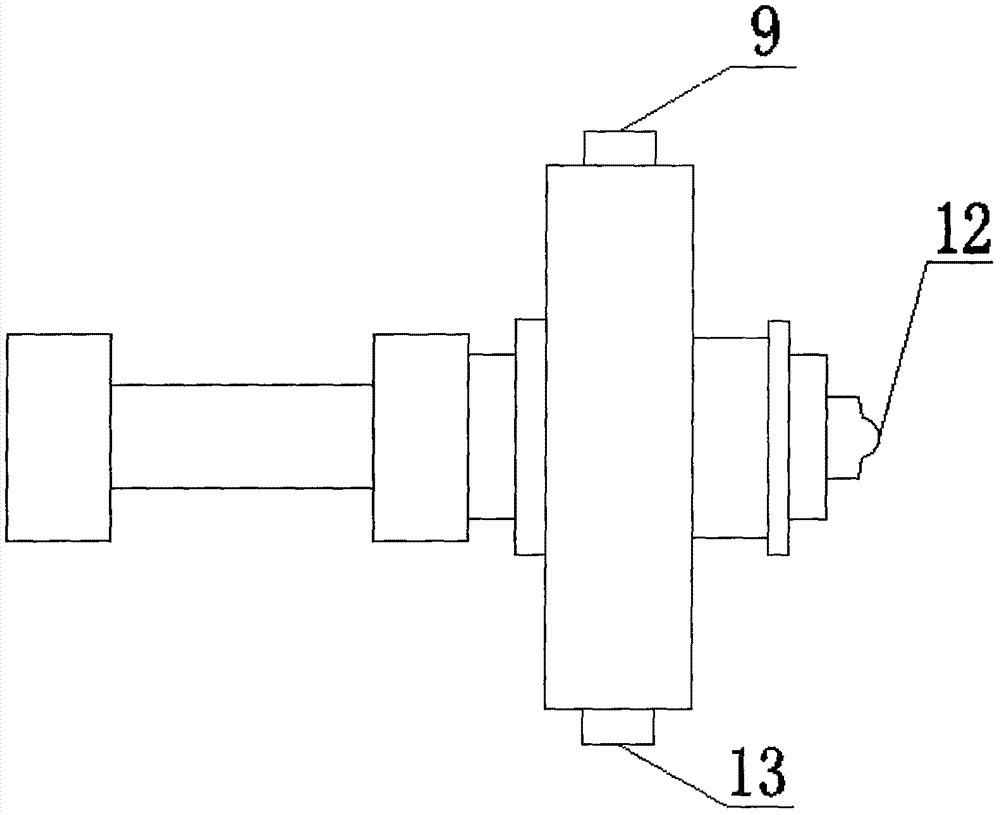

[0013] Attached below figure 1 and figure 2 The present invention is described further:

[0014] A dual-flow hydraulic variable transmission system, including power supply 1, single-chip microcomputer 2, radar 3, one-way valve 4, liquid pressure gauge 5, liquid flow meter 6, valve one 7, valve two 8, nozzle liquid end 9, medicine box 10. Liquid pump 11, nozzle body 12, nozzle gas end 13, characterized in that: the liquid pump 11 is connected to the medicine box 10, the one-way valve 4 is connected to the liquid pump 11, and the liquid pressure gauge 5 is connected to One-way valve 4, the liquid flowmeter 6 is connected to the liquid pressure gauge 5, the valve one 7 and valve two 8 are connected in parallel and connected to the liquid flowmeter 6 and the nozzle liquid end 9 respectively, the nozzle liquid end 9, the nozzle The main body 12 and the gas end 13 of the spray head together form a double-flow spray head. The radar 3 is connected to the single-chip microcomputer 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com