Software virtualization technology based material level detection method

A virtual technology and material level detection technology, which is applied in the field of material level detection, can solve the problems that the feeding efficiency and accuracy cannot be guaranteed, the occupational health of workers cannot be guaranteed, and the material deviation cannot be overcome, so as to save spare parts replacement and save Hardware investment cost, effect of occupational health improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

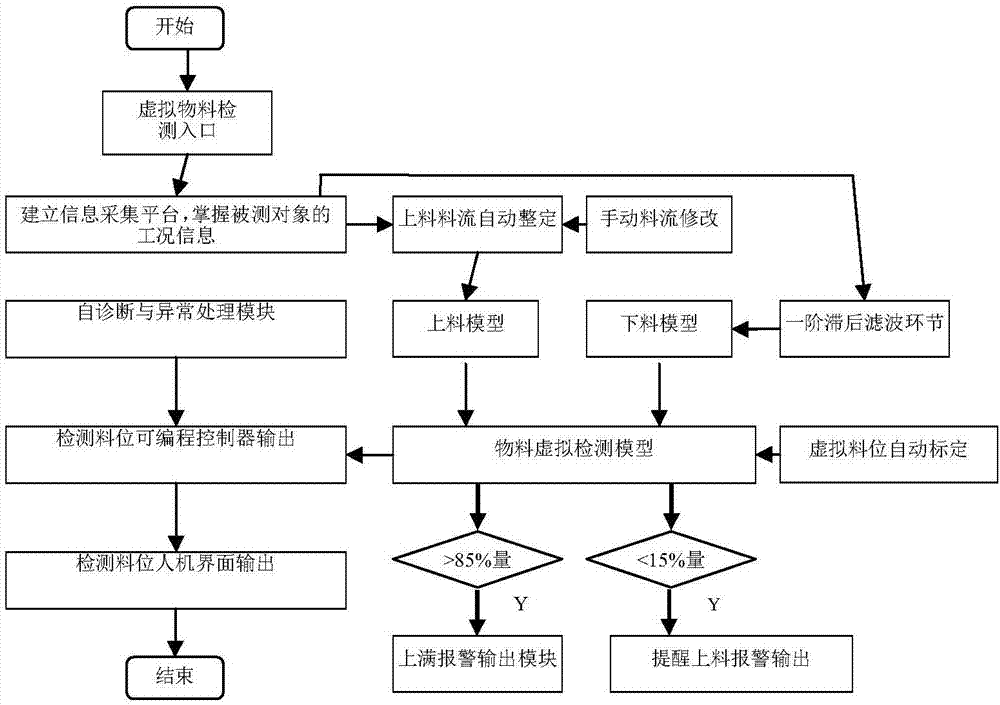

[0031] Usually, before the transformation of the material level detection system, the feasibility evaluation of the original material level detection system is carried out, that is, the feasibility analysis of the detection components of the upper and lower processes of the measured object is carried out, and the measurement accuracy of the virtual material detection For evaluation, the lower-level process of the measured object must have a physical detection link, and the operation and accuracy are relatively reliable. The material detection of the upper-level process can be detected by physical components or calculated by the running time of the feeding equipment. Several typical silos were used for testing during the evaluation. By preliminarily calculating the feeding amount of the upper-level process minus the loss and error, it is compared with the consumption of the lower-level materials. If the deviation is less than or equal to 80%, it is concluded that the transform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com