Brake input pressure measurement sensor for disc brake

A technology for measuring sensors and disc brakes, which is applied in force/torque/work measuring instruments, measurement of the properties of piezoelectric devices, measuring devices, etc. , large braking force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

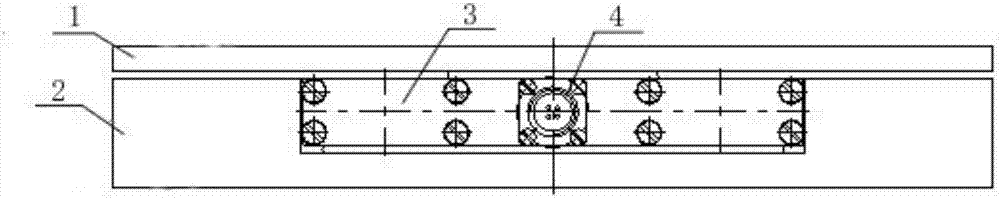

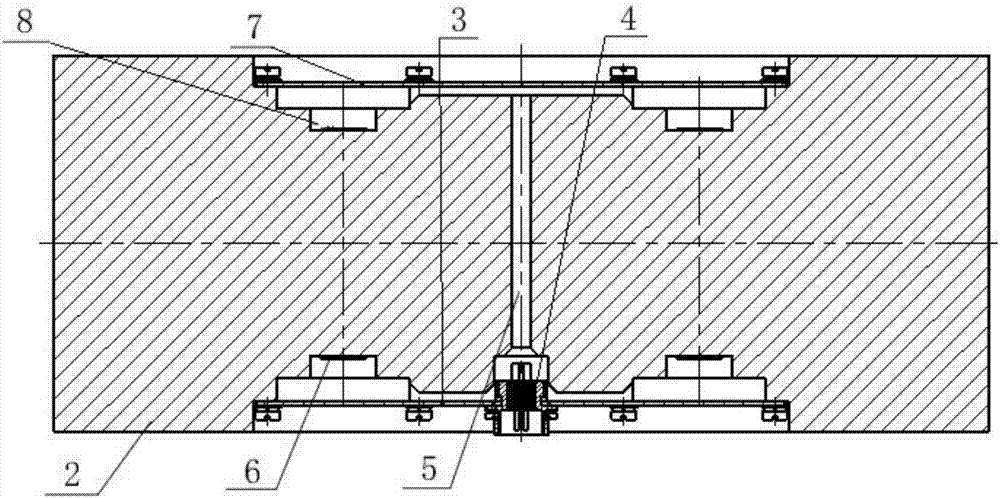

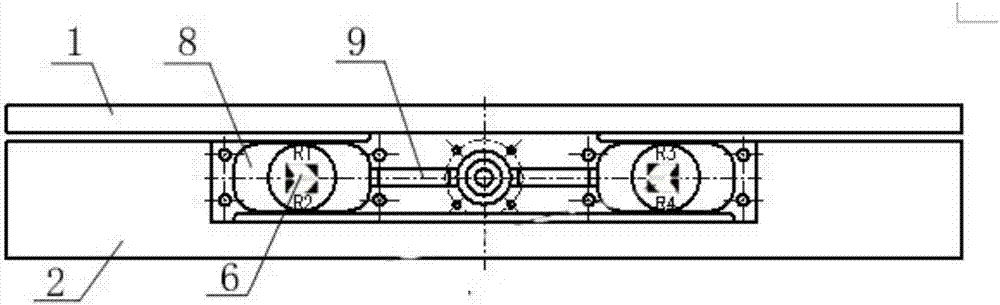

[0021] combine figure 1 , figure 2 and image 3 As shown, the present invention includes a pressure bearing plate 1 and a support plate 2 installed horizontally and parallel to each other, the pressure bearing plate 1 and the support plate 2 are rectangular plates, the pressure bearing plate 1 is supported and connected above the support plate 2, and the pressure bearing plate 1 and the support plate 2 form an I-shaped structure. Grooves are provided on the front and rear sides of the support plate 2, and two blind holes 8 are arranged in the grooves on the front and rear sides. The front and rear grooves are symmetrical to each other, and the four blind holes 8 are symmetrical to each other.

[0022] The sensor is flat as a whole, bears force from top to bottom, and adopts a blind hole 8 shear symmetrical beam integrated strain measurement structure. Simulate the way ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com