Rubber Composition And Pneumatic Tire Comprising Tread Formed From Said Rubber Composition

一种橡胶组合物、化合物的技术,应用在特殊轮胎、轮胎零部件、运输和包装等方向,能够解决低燃耗性、橡胶组合物硬度升高、加工性恶化等问题,达到改善低燃耗性、良好加工性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0128] The present invention is specifically described based on examples, but the present invention is not limited to them.

[0129] Various chemicals used in the production examples are described below.

[0130] Ion-exchanged water: manufactured by our company

[0131] Potassium abietate soap: manufactured by Harima Chemicals, Inc.

[0132] Fatty acid sodium soap: manufactured by Wako Pure Chemical Industries, Ltd.

[0133] Potassium chloride: manufactured by Wako Pure Chemical Industries, Ltd.

[0134] Sodium naphthalenesulfonate formaldehyde condensate: manufactured by Kao Co., Ltd.

[0135] 1,3-butadiene: 1,3-butadiene manufactured by Takachiho Shoji Co., Ltd.

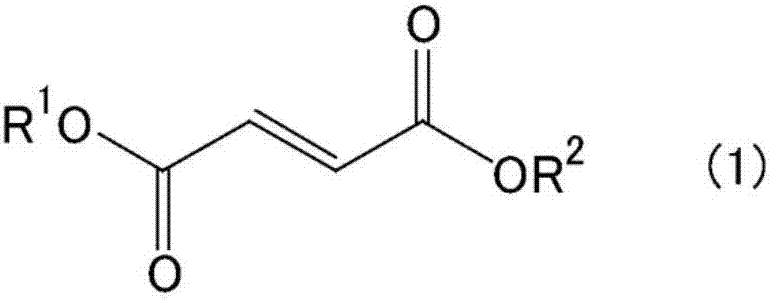

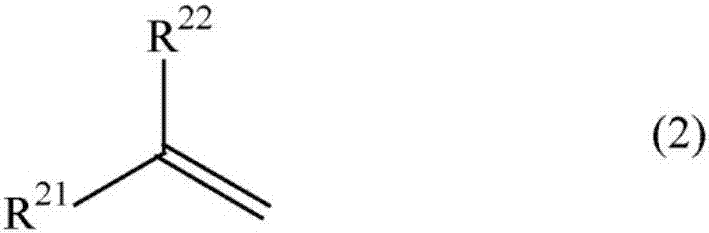

[0136] Styrene: Styrene manufactured by Wako Pure Chemical Industries, Ltd. (compound represented by formula (2))

[0137] Tert-dodecyl mercaptan: tert-dodecyl mercaptan (chain transfer agent) manufactured by Wako Pure Chemical Industries, Ltd.

[0138] Si363: 3-[ethoxybis(3,6,9,12,15-pentoxaoctadecyl-1-yloxy...

manufacture example 1

[0155] A stainless steel polymerization reactor with an internal volume of 50 liters was washed, dried, and replaced with dry nitrogen, and then 3,500 g of 1,3-butadiene, 1,500 g of styrene, 5.74 g of t-dodecyl mercaptan, and the above-mentioned emulsifier were added. 9688g, sodium hydrosulfide 6.3ml (1.8M), active agent (FeSO 4 / EDTA / rongalit) and 6.3 ml (2.3 M) of the polymerization initiator were polymerized at 10° C. for 3 hours while stirring. After the polymerization, add 2.9g of N,N-diethylhydroxylamine, carry out the reaction for 30 minutes and take out the contents of the polymerization reaction vessel, add 10g of 2,6-di-tert-butyl-p-cresol, and evaporate most of the water , and then dried under reduced pressure at 55°C for 12 hours to obtain Copolymer 1.

manufacture example 2

[0157] The copolymer 2 was obtained by the same method except having changed 1,500 g of styrene in the said manufacture example 1 into 1,500 g of diethyl fumarate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com