Preparation method of metal-organic framework material mil-88b(fe)

A metal-organic framework and organic ligand technology, applied in the preparation of metal-organic framework material MIL-88B, the preparation field of metal-organic framework material MIL-88B under normal temperature conditions, can solve the complicated washing and activation process, amplification reaction limitation, Improve production costs and other issues to achieve the effects of reducing synthesis costs, reducing usage, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Weigh 0.354g Fe(NO 3 ) 3 9H 2 O. Put 0.146g of terephthalic acid in a mortar, grind vigorously for 10min to make it evenly mixed, and then transfer the mixture into a 10mL ball mill jar. The volume ratio of large, medium and small ball milling beads is 1:6:3. Occupying 1 / 2 of the volume of the ball milling jar, the materials of the ball milling beads and the ball milling jar are both alumina ceramics, milled at a speed of 420rpm for 1 hour, took out the ball-milled mixture, transferred it to a 20mL glass bottle, added 5mL of ethanol, and ultrasonicated After 15 minutes, the reaction was carried out at a stirring speed of 600 rpm for 12 hours.

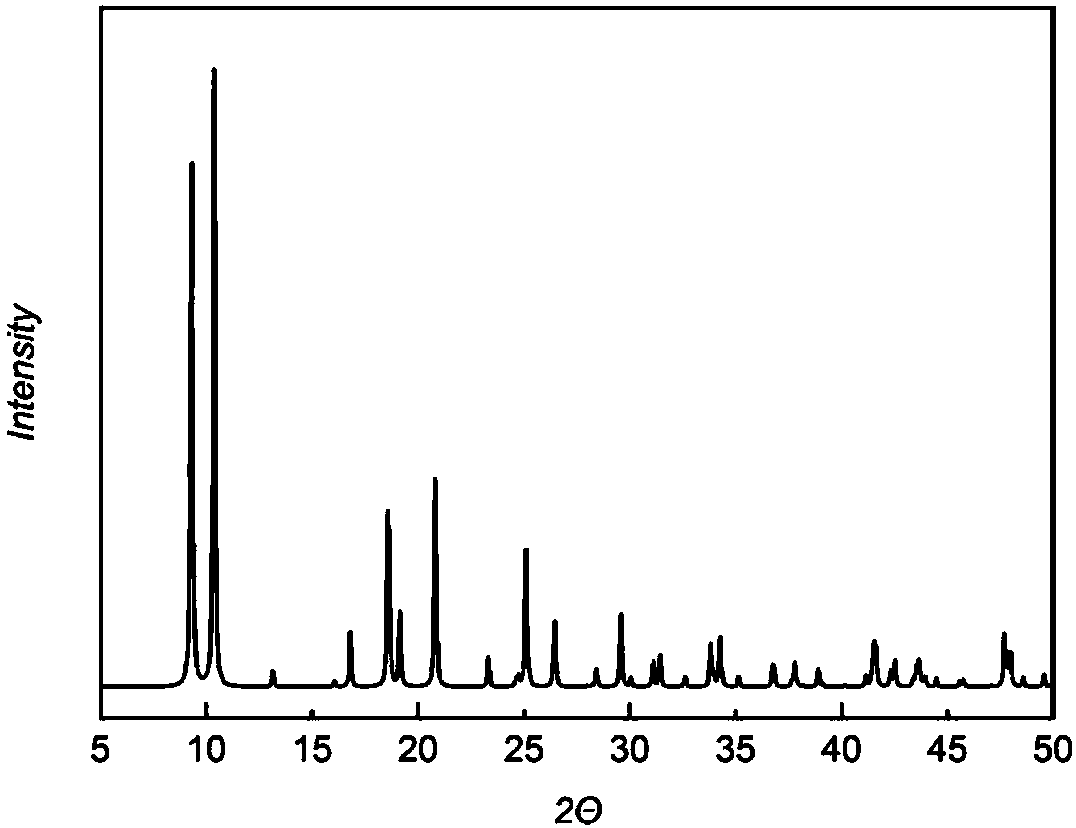

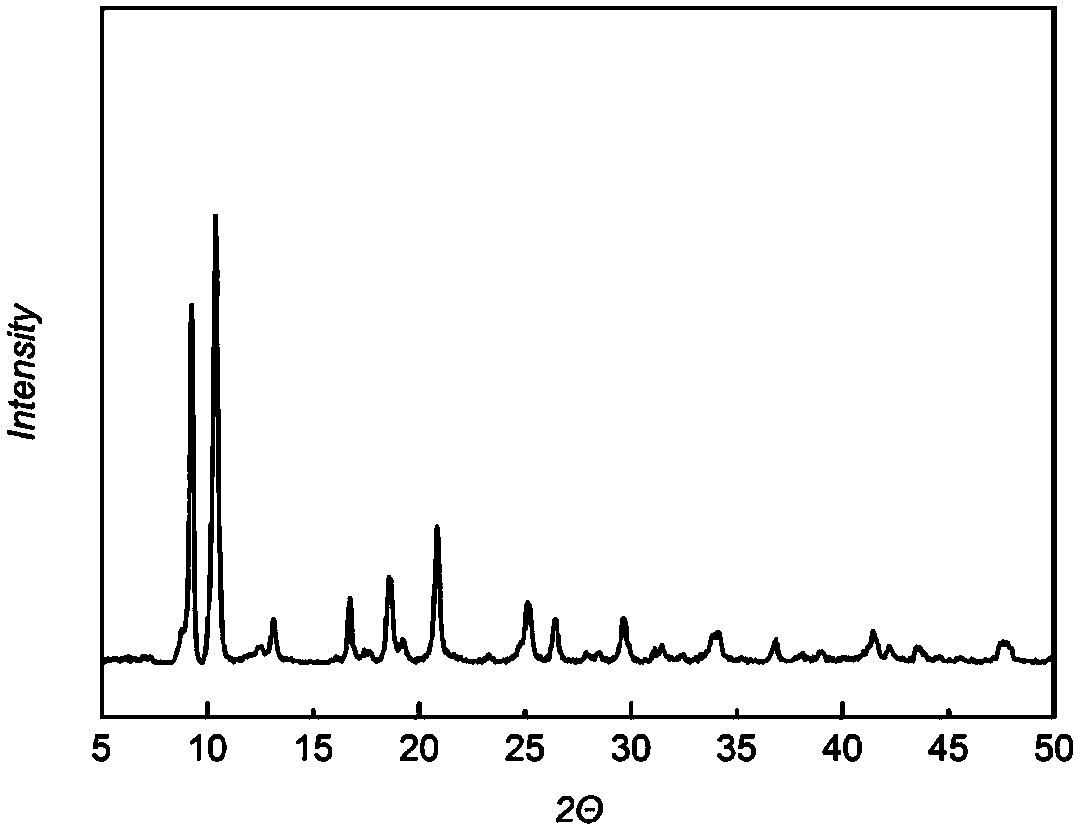

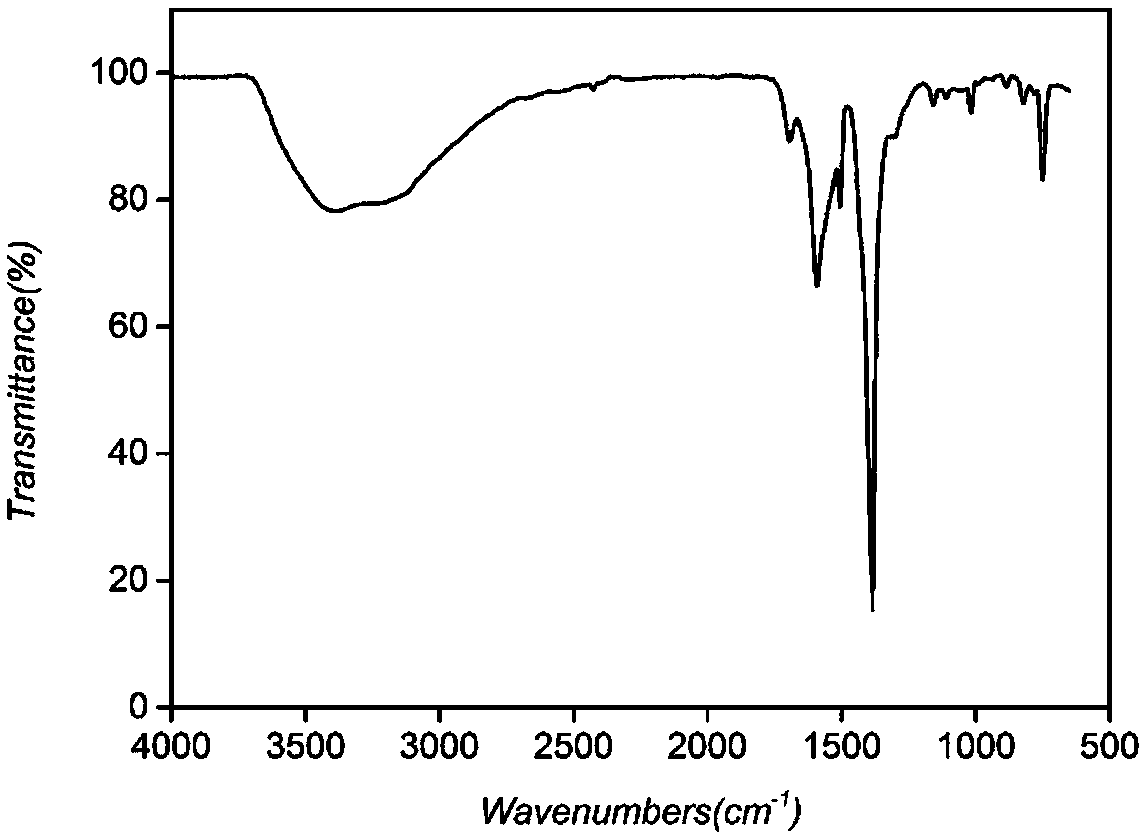

[0045] The reacted crude product was obtained by centrifugation, washed with ethanol several times, and the washed crude product was vacuum-dried to obtain 0.1568 g of the product with a yield of 51%. Through XRD analysis, its characteristic peak (see figure 2 ) and fitted MIL-88B(Fe) characteristic peaks (see figure 1 ) ar...

Embodiment 2

[0047] Weigh 0.354g Fe(NO 3 ) 3 9H 2 0.0.146g of terephthalic acid in a mortar, grind vigorously for 15min to make it evenly mixed, then move the mixture into a 10mL ball mill jar, the volume ratio of the large, medium and small ball mill beads is 1:6:3, Occupying 1 / 2 of the volume of the ball milling jar, the ball milling beads and the ball milling jar are made of alumina ceramics, milled at a speed of 420rpm for 2h, take out the ball-milled mixture, transfer it to a 20mL glass bottle, add 5mL of ethanol, and ultrasonically After 15 minutes, react at 600 rpm for 12 hours.

[0048] The reacted crude product was obtained by centrifugation, washed with ethanol for several times, and the washed crude product was vacuum-dried to obtain 0.1682 g of the product with a yield of 54%. Through XRD analysis, its characteristic peak (see Figure 4 ) and fitted MIL-88B(Fe) characteristic peaks (see figure 1 ) are consistent, indicating that the obtained crystals are pure MIL-88B(Fe), ...

Embodiment 3

[0050] Weigh 0.237g FeCl respectively 3 ·6H 2 O. Put 0.146g terephthalic acid in a mortar, grind vigorously for 10min to make it evenly mixed, then move the mixture into a 10mL ball mill jar, the volume ratio of large, medium and small ball mill beads is 1:6:3, accounting for 1 / 2 of the tank volume, the ball milling beads and the ball milling tank are made of alumina ceramics, milled at 420rpm for 1h, take out the ball-milled mixture, transfer it to a 20mL glass bottle, add 5mL of ethanol, and ultrasonicate for 15min , Reacted for 12h at a stirring speed of 600rpm.

[0051] The reacted crude product was obtained by centrifugation, washed several times with ethanol, and vacuum-dried the washed crude product to obtain 0.1864 g of the product with a yield of 60%. Through XRD analysis, its characteristic peak (see Figure 6 ) and fitted MIL-88B(Fe) characteristic peaks (see figure 1 ) are consistent, indicating that the obtained crystals are pure MIL-88B(Fe), and the results o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com