Conveying guide roller for rapid expanding and setting of high-performance films

A tenter setting and high-performance technology, which is applied to the field of fast tenter setting and conveying guide rollers for high-performance films, can solve the problems of inability to completely solve the problem of wrinkling and shrinkage, reducing the cooling shrinkage rate of the film, and unable to remove wrinkles and flatten the film. Achieve ideal wrinkle removal and smoothing effect, increase friction coefficient, and ensure wrinkle removal and smoothing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

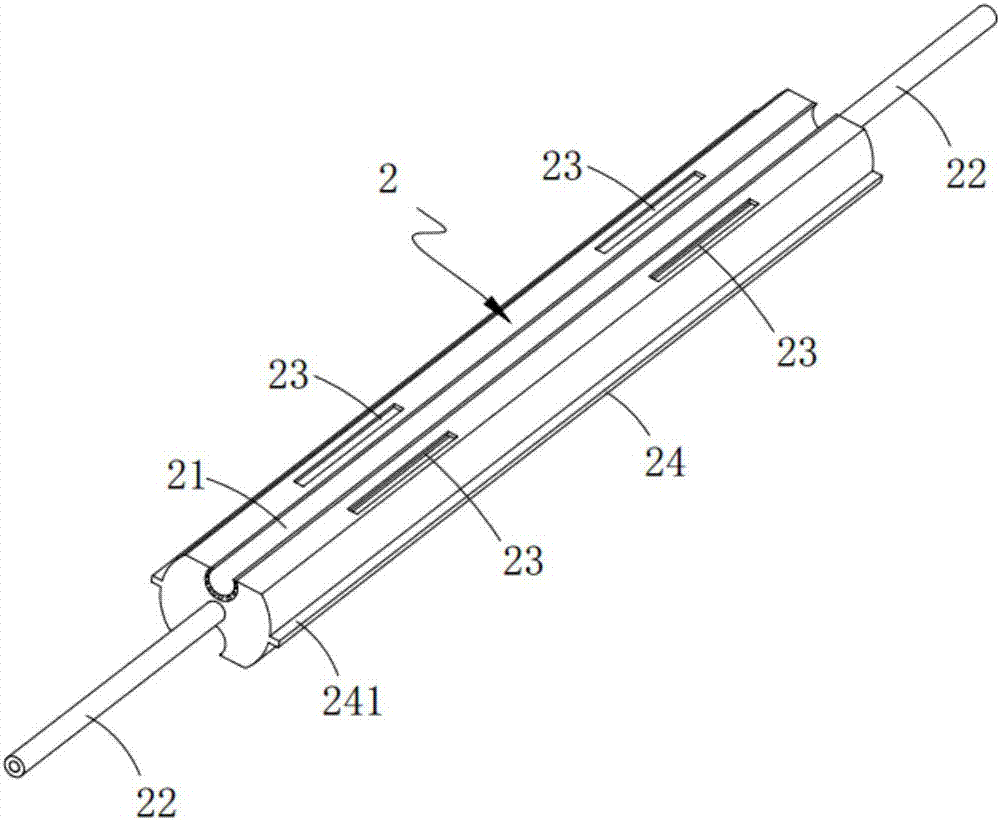

[0039] like figure 1 and figure 2 As shown, a high-performance film is used for rapid tentering and setting conveying guide rollers, including a limit mechanism 1, a guide roller 2 and a leveling mechanism 3 that is slidingly fitted on the guide roller 2, and the two ends of the guide roller 2 They are respectively installed in rotation on the corresponding limit mechanism 1, and a guide cavity 20 is opened inside; the leveling mechanism 3 includes a leveling assembly 30 arranged symmetrically along the radial direction of the guide rail roller 2, and the leveling assembly 30 includes a The smoothing unit 31 arranged symmetrically in the axial direction of the roller 2, the smoothing unit 31 includes a smoothing slider 311 with a cooling cavity 310 inside and a push-pull mechanism 312, one end of the push-pull mechanism 312 is fixedly connected with the smoothing slider 311, and the other end is connected with the smoothing slider 311. The corresponding limit mechanism 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com