A four-link glass cleaning robot

A glass-wiping robot and four-link technology, applied in the field of robotics, can solve the problems of increasing the mass of the robot body, increasing the cost of the motor, and inconvenience in walking, etc., and achieve the effect of smooth movement of the robot, light mechanism operation, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Specific examples of the present invention are given below. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the claims of the present application.

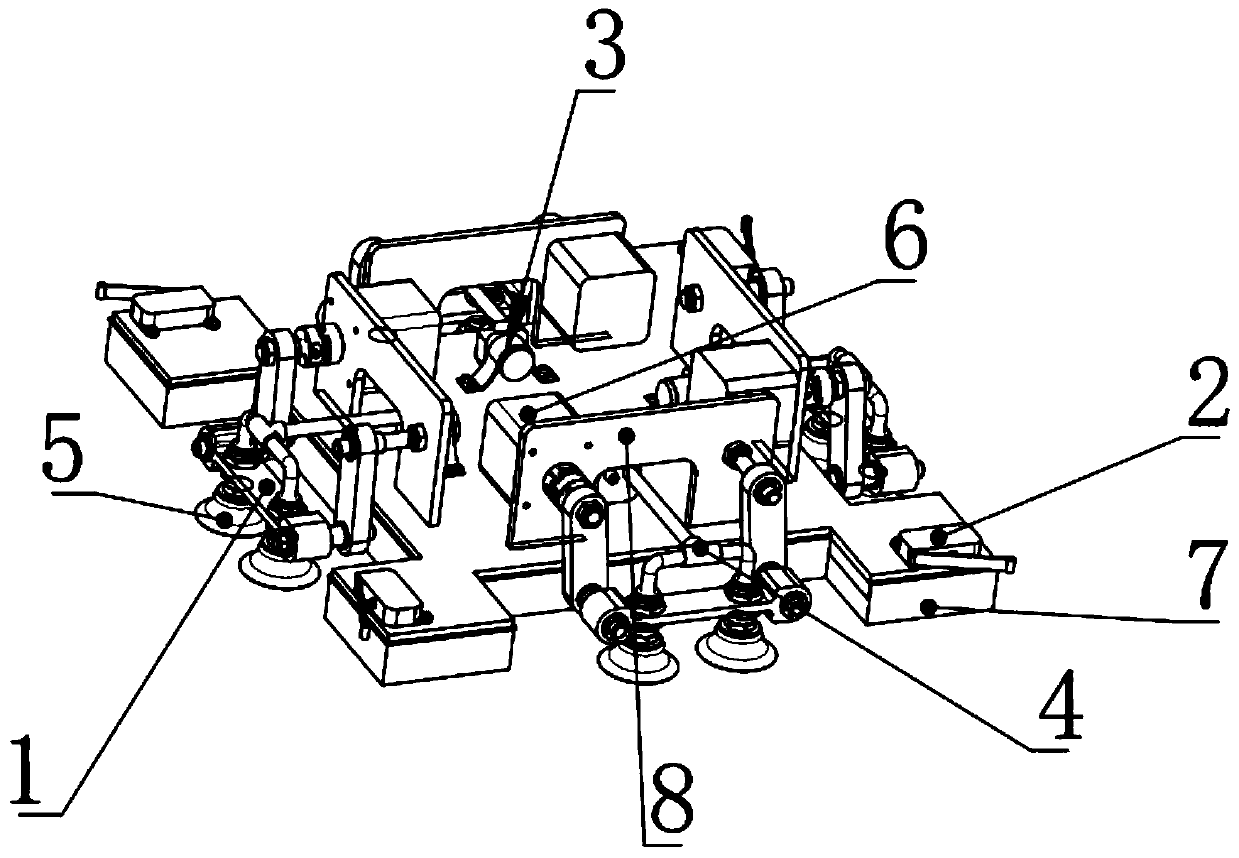

[0026] The invention provides a four-link glass cleaning robot (see Figure 1-7 , referred to as the robot), including a four-bar linkage assembly 1, a sensor assembly 2, a micro-vacuum pump assembly 3, an air circuit 4, a spring suction cup assembly 5, a motor assembly 6, a glass wiping cloth assembly 7 and a frame assembly 8;

[0027] The frame assembly includes a bottom plate 81, a motor support plate 82 and a ball universal wheel 83; the motor support plate 82 and the ball universal wheel 83 are fixed on the bottom plate 81 by screws;

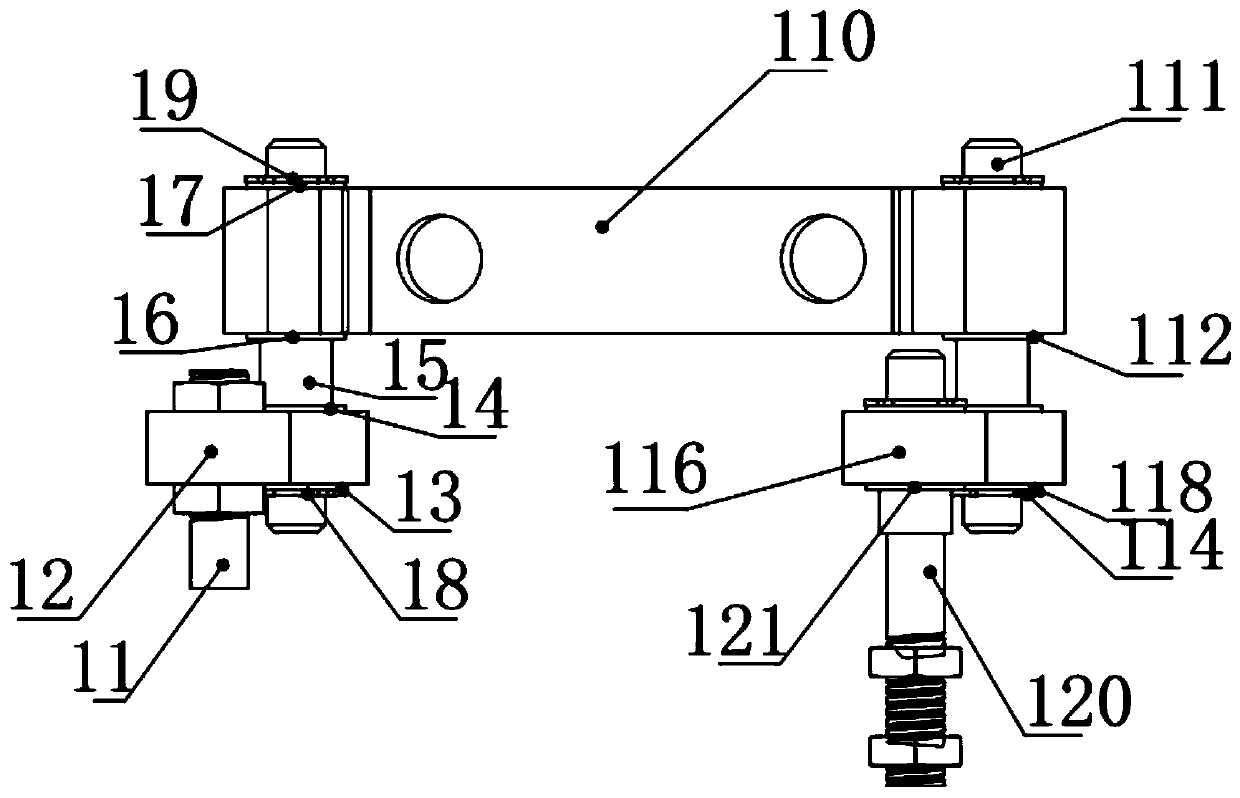

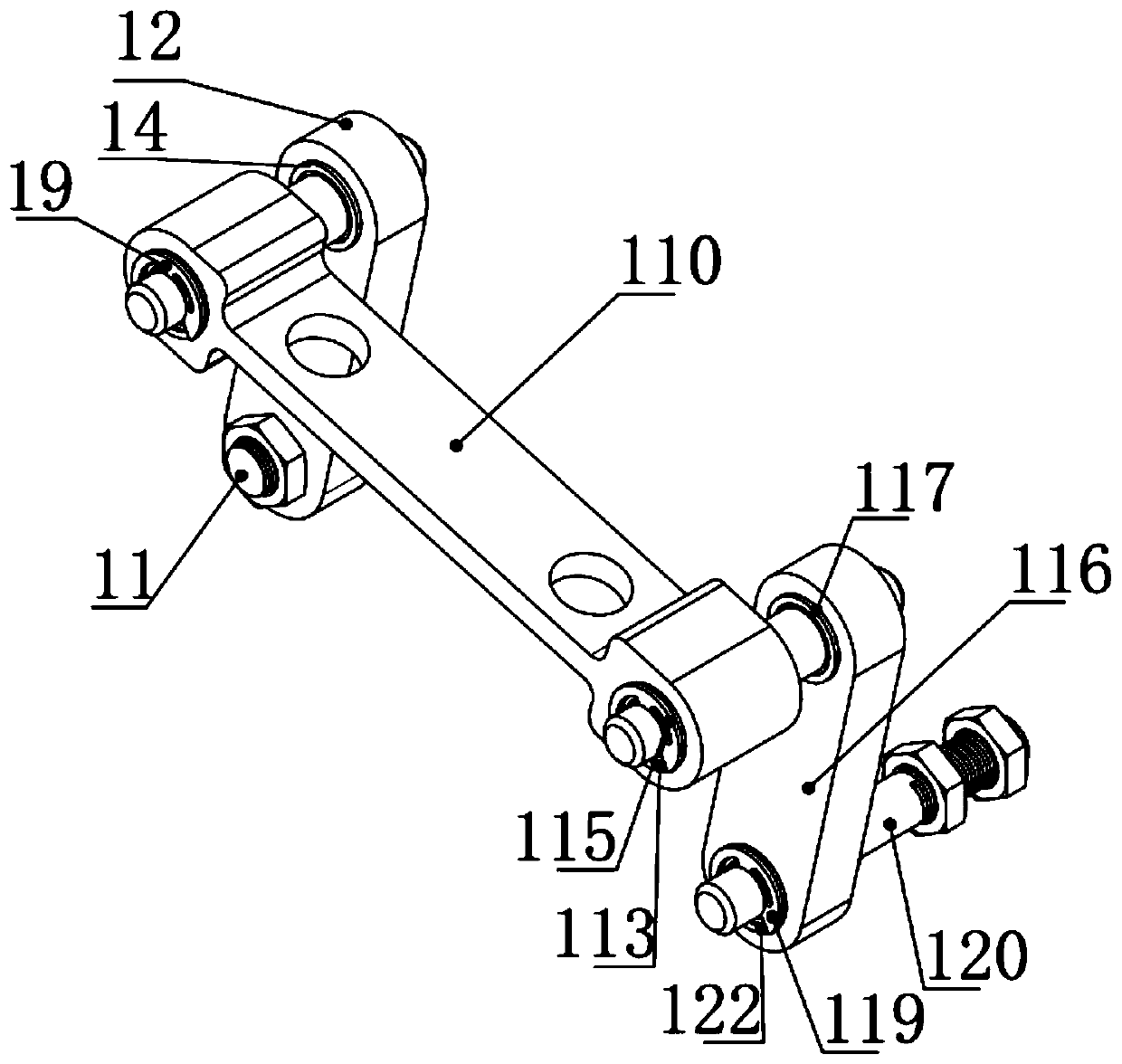

[0028] The four-bar linkage assembly 1 is composed of four four-bar linkages with the same structure; the four-bar linkage includes a motor connecting shaft 11, a crank 12, a crank left flange bearing 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com