Sound sensing circuit based on operational amplifier

A circuit and detection circuit technology, applied in transducer circuits, sensors, electrical components, etc., can solve the problems of component accuracy fluctuation, poor consistency, and high cost, and achieve stable circuit output waveform, reduce complexity, and circuit stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] In order to better understand the technical content of the present invention, specific examples are given and described as follows in conjunction with the accompanying drawings.

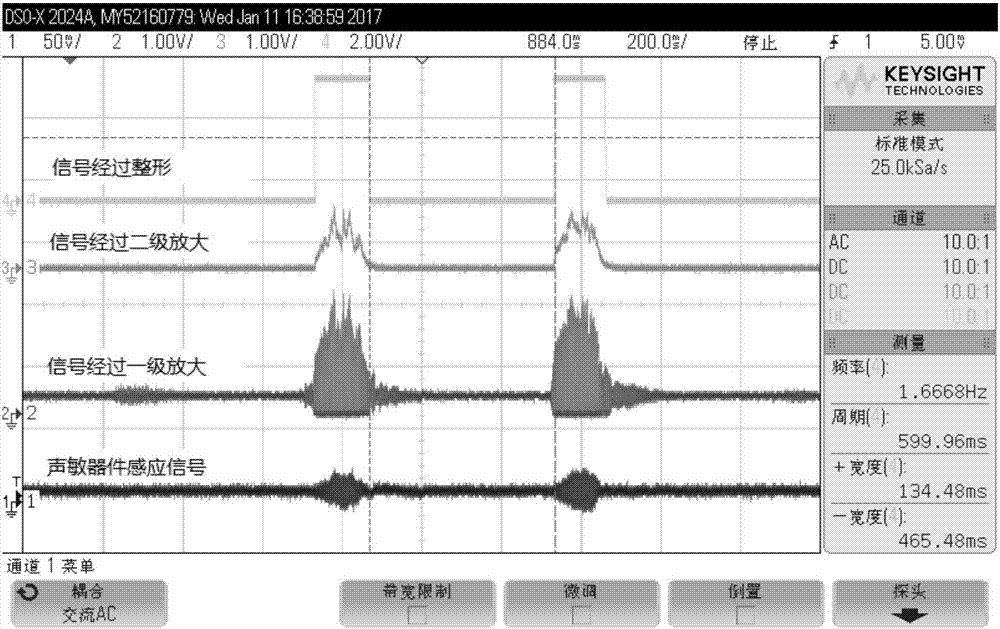

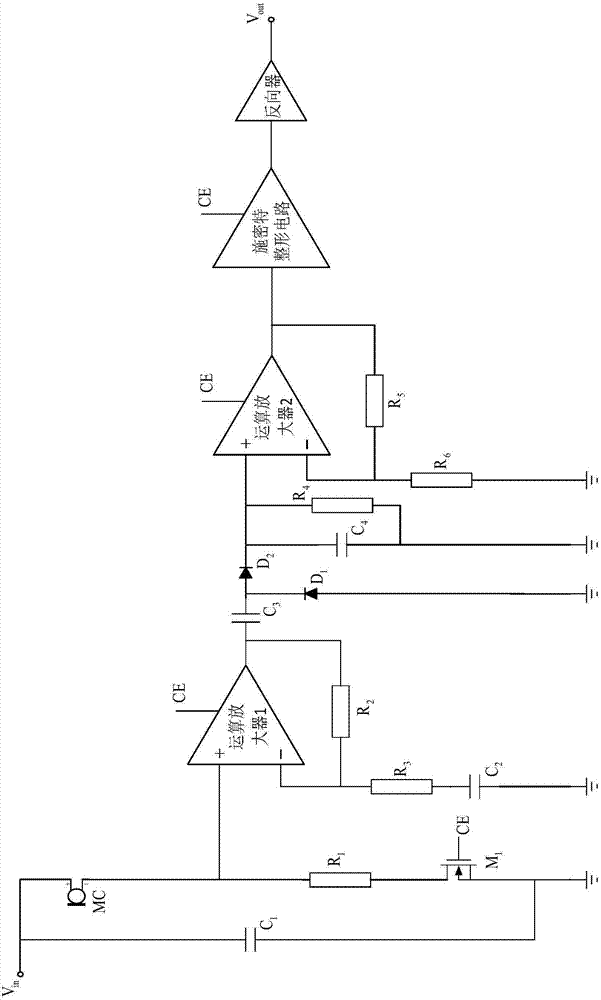

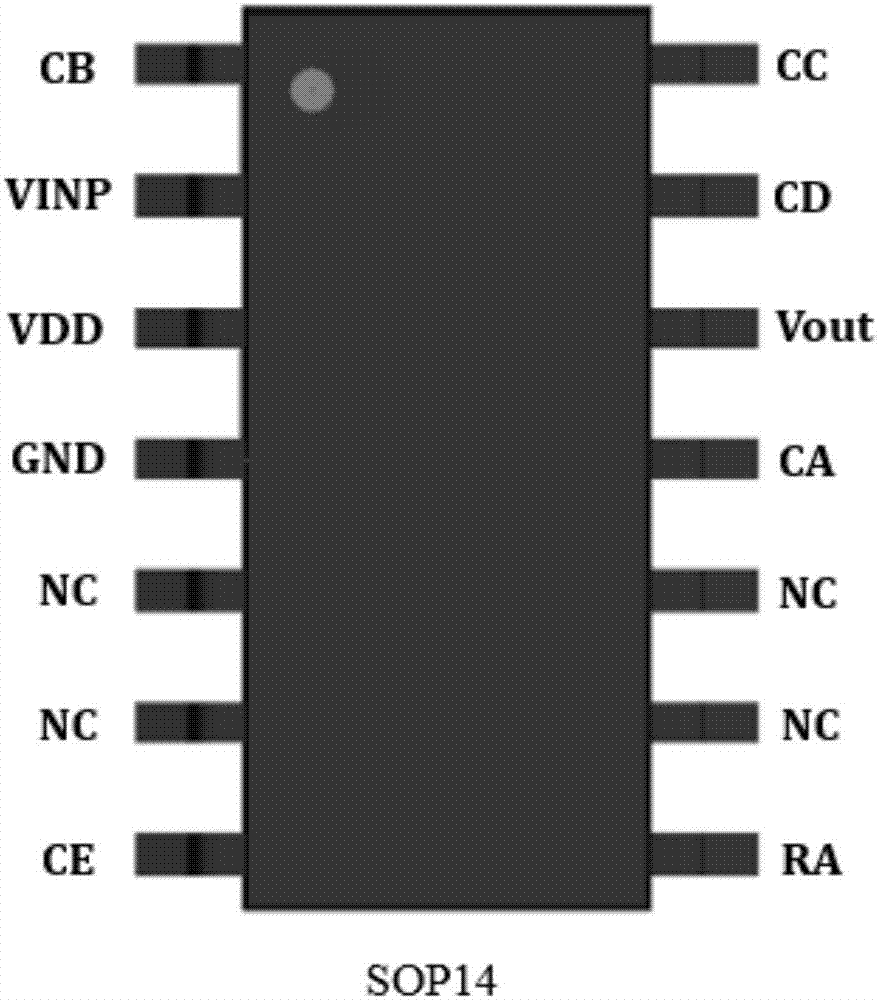

[0062] See figure 1As shown, this is the electrical schematic diagram of the acoustic sensing circuit based on the operational amplifier of the present invention. The acoustic sensing circuit based on the operational amplifier of the present invention includes a sound signal detection circuit, a primary amplifier circuit, a signal processing circuit, a secondary amplifier circuit and a shaping circuit. The enable signal CE controls the working states of M1, operational amplifier 1, operational amplifier 2 and the Schmidt shaping circuit. The positive terminal of the microphone (microphone) MC is connected to the input voltage Vin, the negative terminal is connected to the drain of M1 through the resistor R1, the source level substrate of M1 is grounded, the gate of M1 is connected to the cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com