Method for determining maximum dry density of natural-gradation sand and gravel materials for damming

A technology of maximum dry density and gravel materials, applied in the direction of analyzing materials, measuring devices, instruments, etc., can solve the problems of damaged vibrating mill, inaccurate test results, tilted density bucket, etc., to improve accuracy, ensure rolling effect, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

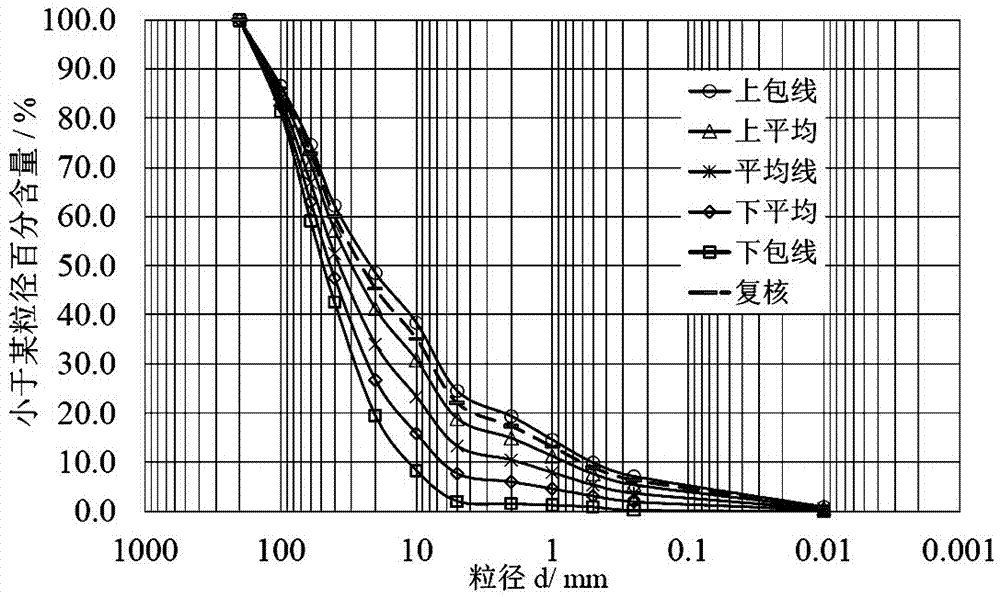

[0034] Taking a large reservoir as an example, the main dam uses clay core wall gravel (pebble) stone dam, and the dam shell material is designed as natural graded gravel (pebble) stone. The main problems in the stockyard are: due to the serious phenomenon of artificial sand mining in recent years As a result, the fine particles of gravel (pebble) in the upper layer of the stockyard are missing, and the natural gradation curve, physical and mechanical parameters, mining conditions, etc. of the gravel (pebble) in the stockyard are changed. Due to the large change in the gradation range of the disturbance material after manual mining, the dispersion is large. In order to ensure the construction quality of the dam, it is very critical to further clarify the gradation envelope of the upper dam material and determine the control standards and control indicators of the dam filling before the dam construction.

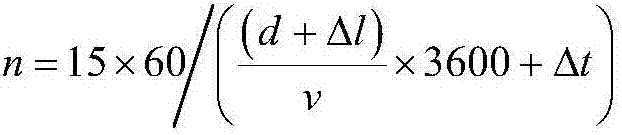

[0035] Adopt the method that the present invention determines the maximu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com