Universal roller type variable diameter centralizer

A universal roller and centralizer technology, applied in drilling equipment, earthwork drilling, drill pipe, etc., can solve problems such as limited centering effect, lack of centralizing effect, and large frictional resistance on the well wall to achieve hydraulic pressure drive Convenience, reduced friction, improved wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

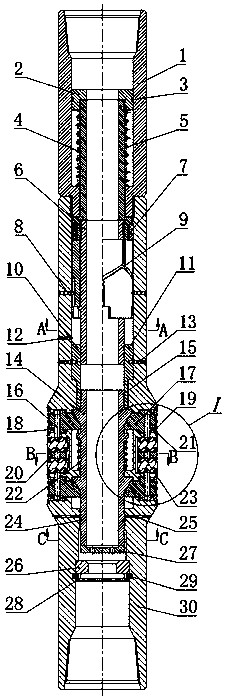

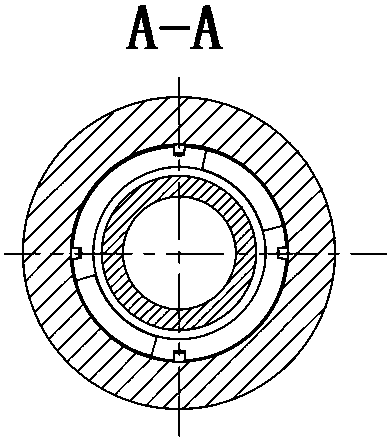

[0026] The technical solutions in the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings in the embodiments of the present invention:

[0027] Referring to the accompanying drawings, the universal roller type variable diameter centralizer is composed of a variable diameter mechanism, a universal roller mechanism, an upper joint 1, and a body 30. The variable diameter mechanism includes a piston 2, a sealing ring a3, a return spring 4, and a piston rod 5. Push cylinder 6, bearing group 7, guide pin 8, guide block 9, seal ring b10, core rod 14, seal ring c15, plunger 17, compression spring 18, plunger cover 19, screw a21, core rod spring 22 , the rear end of the piston rod 5 is connected to the piston 2 through threads, one end of the return spring 4 bears against the piston 2, and the other end bears against the inner step of the upper joint 1, and the piston 2 is sealed with a sealing ring a3 to prevent mud from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com