Anchor rod bracing wire foundation applicable to rock base and construction method thereof

A rock foundation and bolt technology, which is applied in the construction field of the bolt and cable foundation, can solve the problems of foundation safety hazards, poor cable stability, and loose connection, etc., and achieves the elimination of safety hazards, strong pull-out resistance, and not easy to suffer. pull cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the scope of protection of the present invention is not limited to the following Described embodiment.

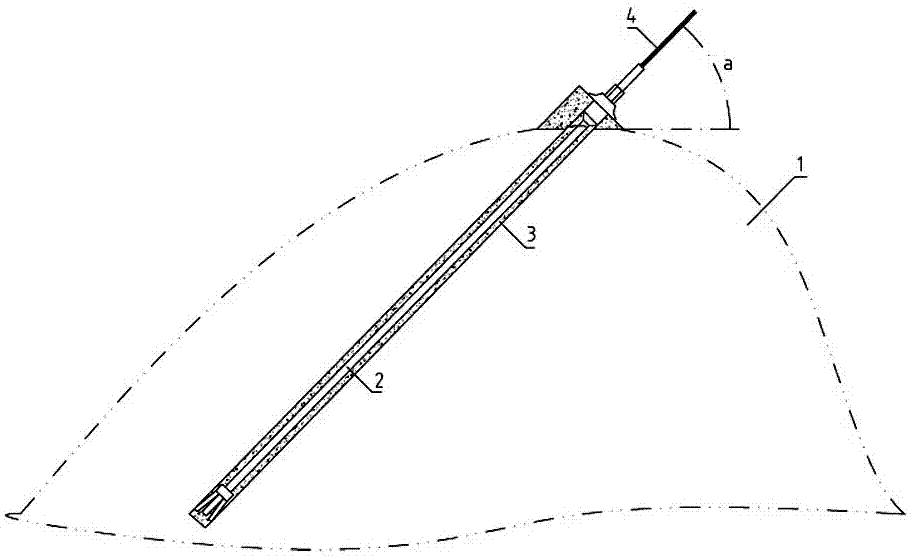

[0027] Such as figure 1 As shown, the bolt and stay wire foundation suitable for rock foundations according to the present invention is composed of a rock hole set on a rock foundation 1, an expanding shell type prestressed hollow grouting bolt 2, a bolt grouting material 3 and a stay wire 4. The angle a formed by backguy 4, expansion shell type prestressed hollow grouting anchor rod 2 and rock hole and horizontal plane is consistent; The other end of the stress hollow grouting anchor 2 is inserted into the rock hole, and the gap between the expansion shell type p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com