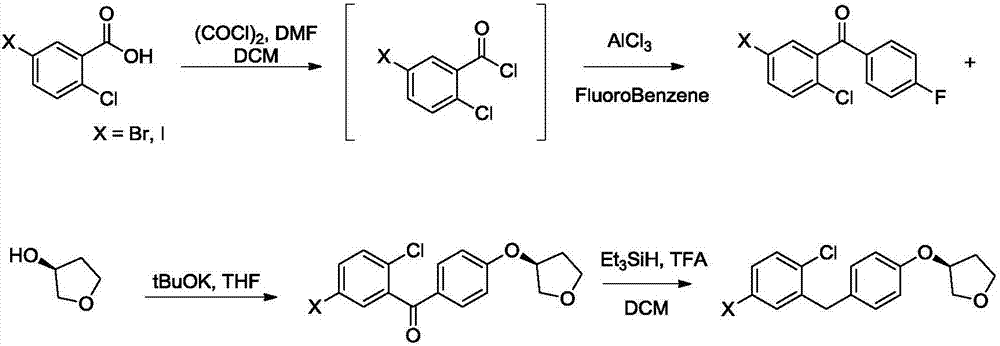

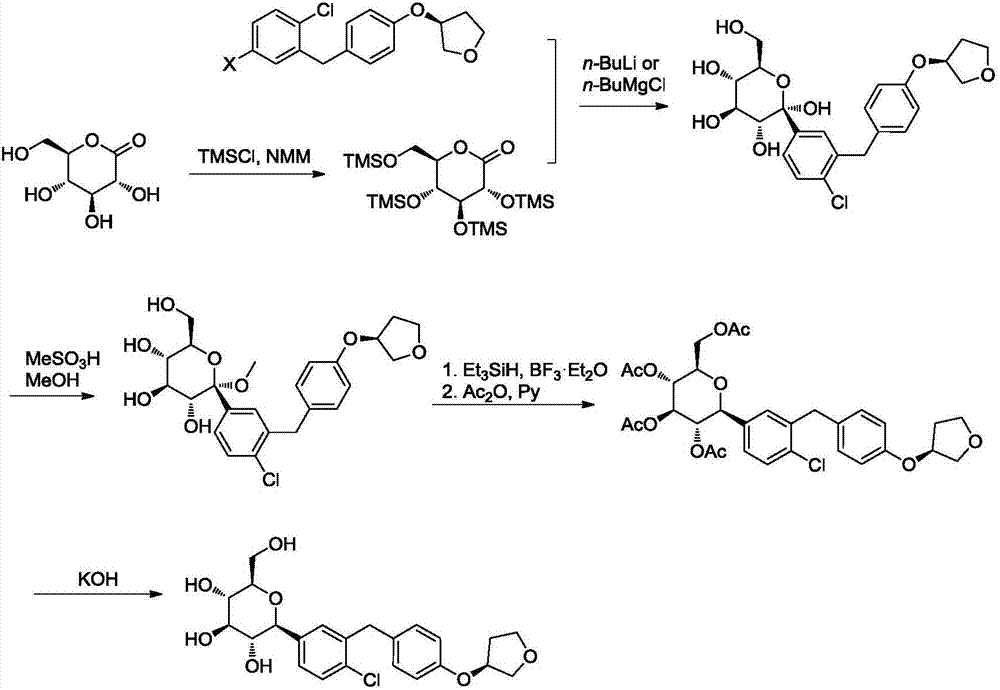

Preparation method of Jardiance

A technology of exchanging empagliflozin and Grignard, which is applied in the field of preparation of empagliflozin for the treatment of diabetes, can solve the problems of selectivity, low yield, unfavorable process amplification, cumbersome route steps, etc., and achieve high product purity, Effect of reducing process cost and shortening reaction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043]

[0044] Add polyphosphoric acid (94mL) into the three-necked flask, add compound formula 1a (23.55g, 100mmol), heat to an internal temperature of about 50°C and stir evenly, add phenol (18.82g, 200mmol), and heat up to 80-85°C after adding ℃ for 3 to 4 hours, after the reaction was completed, cool to 50℃ and slowly add water (235ml) dropwise to quench the reaction, then add dichloromethane (141mL) and stir for 20 minutes. Extracted twice, combined the organic phases, washed once with saturated sodium bicarbonate (141mL) solution, washed twice with saturated brine (70mL), dried over sodium sulfate, concentrated and recrystallized with a mixed solvent of dichloromethane and ethanol to obtain compound 2a (27.11g, 87%). ESI m / z = 311.0 (M+1).

Embodiment 2

[0046]

[0047] Add polyphosphoric acid (113mL) into the three-necked flask, add compound formula 1b (28.25g, 100mmol), heat to an internal temperature of about 50°C and stir evenly, add phenol (18.82g, 200mmol), and heat up to 80-85°C after adding ℃ for 3 to 4 hours, after the reaction was completed, cool to 50 ℃ and slowly add water (283mL) dropwise to quench the reaction, then add dichloromethane (169mL) and stir for 20 minutes, separate the organic phase, and then add dichloromethane (84mL) to the water phase Extracted twice, the combined organic phase was washed once with saturated sodium bicarbonate (169mL) solution, washed twice with saturated brine (84mL), dried over sodium sulfate, concentrated and recrystallized with a mixed solvent of dichloromethane and ethanol to obtain compound 2b (29.76g ,83%). ESI m / z = 358.9 (M+1).

Embodiment 3

[0049]

[0050]Add 2a (31.16g, 100mmol), R-3-chloro-tetrahydrofuran (11.73g, 110mmol), potassium carbonate (27.64g, 200mmol), potassium iodide (830mg, 5mmol) and acetonitrile (155mL) into a three-necked flask, stir well Heat to 50-55°C to react overnight. Concentrate directly to remove part of the acetonitrile after the reaction is completed, add water (155mL) and dichloromethane (155mL), extract the aqueous phase with dichloromethane (78mL) once, combine the organic phases and wash with saturated brine once (155mL), and dry over sodium sulfate , concentrated and then recrystallized from a mixed solvent of petroleum ether and ethyl acetate to obtain compound 4a (34.73 g, 91%).

[0051] Potassium carbonate in embodiment 3 can be replaced by sodium carbonate, cesium carbonate, potassium tert-butoxide, triethylamine or diisopropylethylamine; reaction solvent acetonitrile can be N,N-dimethylformamide, N,N-di Methylacetamide, tetrahydrofuran, 1,4-dioxane, toluene, isopropanol, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com