Device for quickly collecting oil and gas leaked from oil-gas storage tank

A technology of oil and gas storage tanks and collection devices, applied in packaging, transportation, packaging, containers, etc., can solve the problems of complex maintenance process, increased operating costs, and difficult operation, and achieve improved safety factor, low maintenance cost, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and example the present invention will be further described:

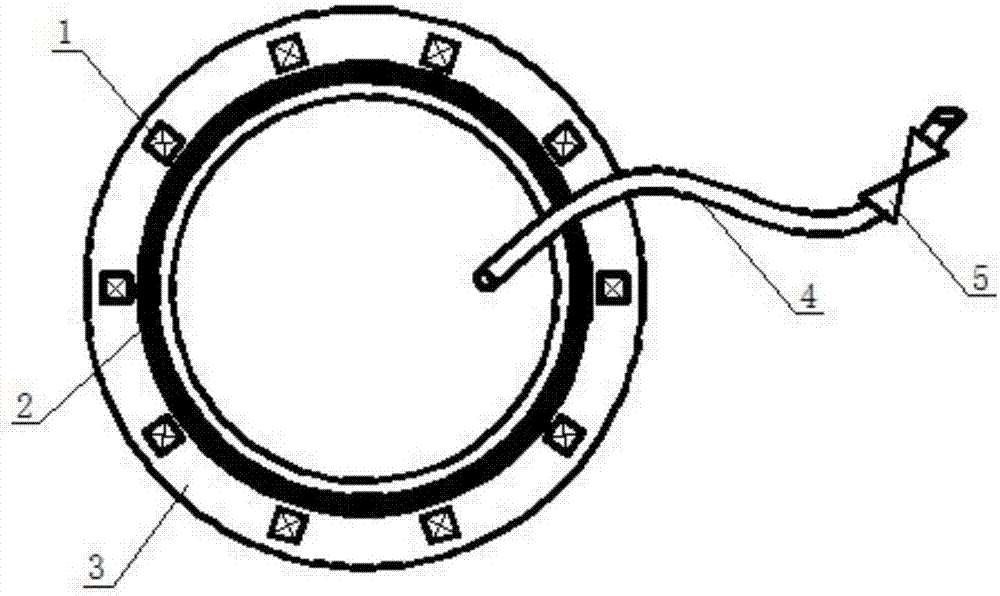

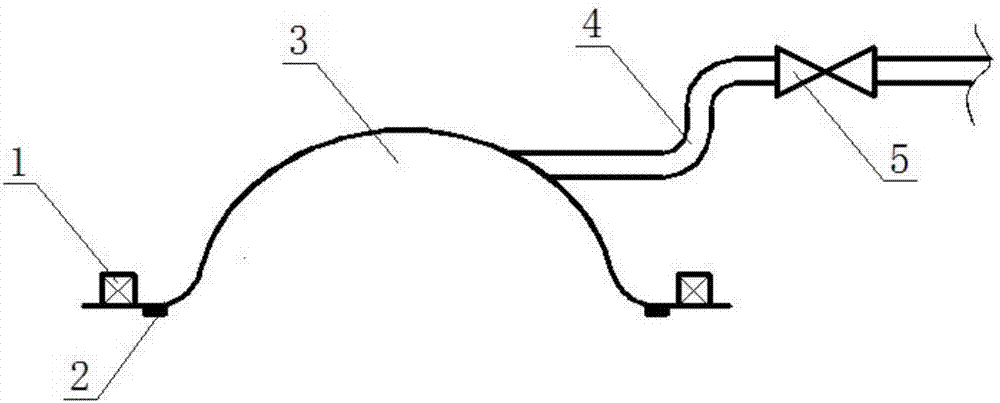

[0013] Such as Figure 1-2 As shown, the device for quickly collecting oil and gas leaked from an oil and gas storage tank provided by the present invention includes a magnet (1), a sealing ring (2), a rubber bladder (3), a conduit (4), a valve (5), a magnet (1) and a storage tank The tanks are attracted to each other, the rubber bladder (3) has a sealing ring (2), the rubber bladder (3) is fixed on the storage tank by the magnetic force between the magnet (1) and the storage tank, and the conduit (4) is connected with the rubber bladder ( 3), a valve (5) is installed on the conduit (4).

[0014] The specific steps for rapid collection of leaked oil and gas by the oil and gas storage tank leakage oil and gas rapid collection device provided in this embodiment are:

[0015] When the oil and gas storage tank leaks, first cover the leak with a rubber bag with a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com